Hyundai Motor Group Hosts 2025 ZER01NE Day Event

AI Robot Process Planning Platform Developer Roai

Technology Implementation Begins at Hyundai Factories This Month

A startup that has developed a platform to optimize robot placement and movement paths using artificial intelligence (AI) is drawing attention from the automotive manufacturing industry. The company is Roai, a technology startup spun off from Hyundai Motor Company’s Manufacturing Solutions Division.

At Hyundai Motor Group’s ‘ZER01NE Day’ held at Hyundai Seongsu Complex Hub in Seongdong-gu, Seoul on September 17, a Roai representative emphasized, “Robot process design that would take more than three months for a human can be completed within a week by utilizing AI.”

The company began full-scale application of its self-developed AI robot process planning platform at Hyundai Motor factories this month. Kia is also running a project, and overseas automakers have shown strong interest. Roai has conducted proof-of-concept (PoC) tests at some General Motors plants, and it is reported that global automakers such as BMW and Rivian are also expressing interest.

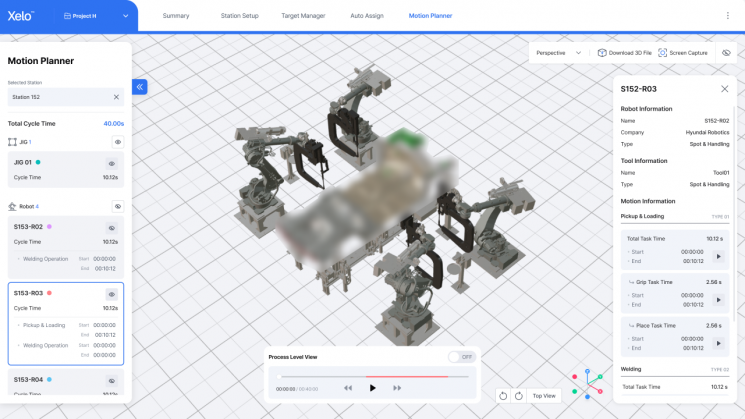

Roai’s AI platform, XELO, calculates the optimal movement and placement of manufacturing robots installed in factories. When a new vehicle is assigned to an assembly line and a new process must be designed, XELO determines how many robotic arms should be installed, what the appropriate spacing should be, and calculates the directions and sequences of movement to avoid collisions with existing structures or robots.

By utilizing this platform, factory movements can be simulated in a virtual environment, reducing both the time and cost required for equipment readjustment. A Roai representative explained, “The time required for factory manufacturing design is reduced by more than 90% compared to manual work, and the work time per process decreases by more than 15%. This means productivity is significantly increased.”

As the deployment of various robots-such as six-axis robots, automated guided vehicles (AGVs), and humanoid robots-is expected to expand in manufacturing sites, the need for platforms that calculate robot movements and optimize factory operations is expected to grow. Another competitive advantage of the company is that the platform is web-based. Once security procedures are approved, authorized personnel can view the status of automated production lines anytime and anywhere, and can also change manufacturing route plans in real time.

Hong Seokui, CEO of Roai, emphasized, “Our goal is to create a future where the entire factory can be operated with a single click,” adding, “We will implement a fully unmanned automated factory by integrating control of various robots and present a new standard for the manufacturing industry.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.