Next-Generation Low-Cost Batteries Emerge as Rivals to Chinese LFP Cells

Industry Welcomes Timely Government Support to Bolster K-Battery Competitiveness

The Ministry of Trade, Industry and Energy has included research and development (R&D) for high-manganese batteries in next year's budget proposal for the first time. This marks the first time that government funding will be directly allocated to the development of next-generation secondary battery technology that increases the proportion of manganese, one of the key materials in batteries. This move is interpreted as a strategic decision to diversify the domestic battery industry's portfolio in response to aggressive low-cost competition from China.

According to the Ministry's 2026 budget plan released on September 3, a new allocation of 5 billion won has been set aside under the title "Development of Core Materials and Cell Manufacturing Technology for High-Manganese Lithium-Ion Secondary Batteries." A Ministry official explained, "The purpose is to help the domestic battery industry avoid overreliance on specific materials and secure a diverse portfolio of low-cost batteries," adding, "The government will play a catalytic role so that companies can continue to develop affordable batteries that can compete with lithium iron phosphate (LFP) batteries."

High-manganese batteries, which are next-generation cells based on lithium and manganese, have consistently drawn attention for their potential to combine the advantages of traditional high-nickel batteries and LFP batteries. The core of this technology is to significantly reduce the use of expensive nickel and cobalt found in conventional NCM (nickel, cobalt, manganese) batteries, while greatly increasing the use of affordable and supply-stable manganese. Notably, the high lithium recovery rate makes these batteries advantageous from a recycling and economic perspective. However, their relatively slow charging speed and shorter lifespan have long been challenges, making technological improvements in these areas a persistent task.

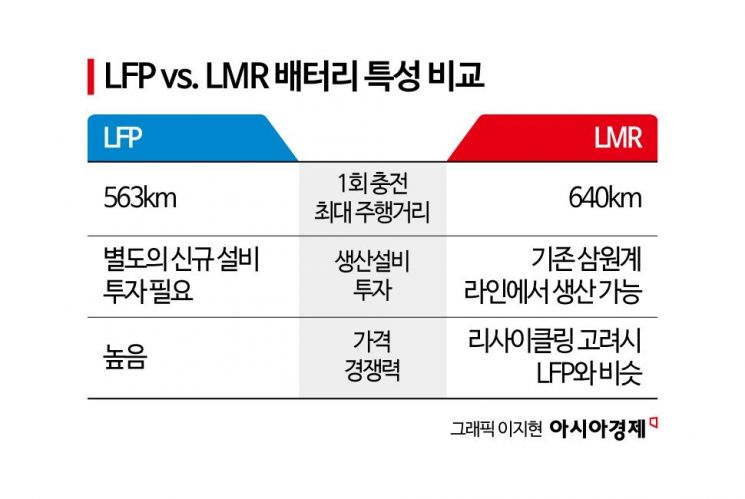

Lithium Manganese Rich (LMR), a representative cathode material for high-manganese batteries, is gaining attention as a next-generation low-cost battery candidate that can replace LFP batteries, as it offers both higher energy density and improved safety. According to industry sources, LMR cathode materials can achieve approximately 33% higher energy density than LFP, enabling greater capacity.

Korean companies are also accelerating the development of high-manganese batteries. POSCO Future M completed the development of LMR cathode materials in May, while EcoPro BM has finished verifying its own LMR cathode material products. Global automakers and battery joint ventures are also stepping up their efforts. Ultium Cells, a joint venture between General Motors (GM) and LG Energy Solution, plans to begin commercial mass production of LMR-based prismatic battery cells in the United States in 2028. This strategy aims to secure both performance and price competitiveness against LFP batteries, which are being supplied in large volumes by Chinese battery companies.

An industry insider commented, "It is encouraging to see support measures for various battery technologies," adding, "As demand grows for affordable, mid- to low-priced batteries with high energy density that can compete with LFP batteries, this is an appropriate move."

Park Jaebum, a senior researcher at POSCO Research Institute, stated, "While LFP batteries have already lost ground to China, focusing on the development of LMR could provide an opportunity to enhance the competitiveness of the domestic battery industry going forward."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.