Ultra-fast, Ultra-precise AI Quality Inspection System Developed

Detects Micro-level Step Defects in 2.79 Seconds

Enables 100% Inspection on Automated Production Lines

Published in Journal of Manufacturing Systems

An ultra-fast and ultra-precise AI quality inspection technology capable of detecting micro-level step defects of several hundred micrometers in just 2.79 seconds has been developed.

On September 1, the team led by Professor Jeong Imdu from the Department of Mechanical Engineering at UNIST announced that they have developed a "smart jig quality inspection system" that combines a 3D-printed sensor cap with an anomaly detection AI algorithm to identify step defects in real time.

Research team, (from left) Professor Jeong Imdu, Researcher Park Seobin (first author), Researcher Kim Taekyung (first author). Provided by UNIST

Research team, (from left) Professor Jeong Imdu, Researcher Park Seobin (first author), Researcher Kim Taekyung (first author). Provided by UNIST

Step defects refer to misalignments in surface height between assembled components, which can lead to weakened joints and overall quality degradation. The main causes include individual component molding errors, impacts or twisting during transport, and other factors. Since these defects cannot be corrected after final assembly processes such as welding, early detection is crucial.

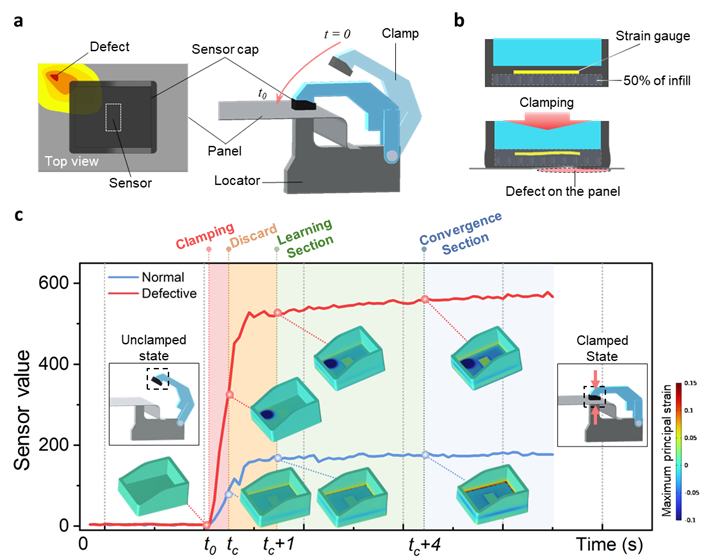

The developed smart jig determines the presence of step defects at the moment components are fixed during the assembly process. A jig is a device that holds components in precise positions for assembly. The research team attached a soft 3D-printed sensor cap to the clamp contact surface of the jig, which acts as the fixing arm. When the clamp grips a component, the attached sensor cap is subtly compressed or expanded to match the surface shape of the part. The AI analyzes these deformation patterns to detect defects.

This technology reduces the inspection time from about 12 minutes to just 2.79 seconds, enabling 100% inspection on fast-moving automated production lines without stopping them. It can also detect ultra-micro step defects as small as several hundred micrometers (μm).

Detected defects are visualized as heatmaps, allowing operators to intuitively identify the location and severity of the defects for immediate response.

The AI model can be trained using only normal product data, making it applicable in real manufacturing environments where collecting defective data and manual labeling are challenging. Additional advantages include low maintenance costs and easy scalability to other manufacturing lines.

Professor Jeong Imdu explained, "This technology can be applied to all industries where high-precision assembly is important, such as mobility, home appliances, semiconductors, and aerospace, where robot-based continuous assembly is performed. It is expected to reduce inspection manpower and time, improve quality reliability, and save hundreds of millions of won annually by minimizing defects."

Operating principle and simulation results of diagnostic technology detecting component defects using AI smart jig.

Operating principle and simulation results of diagnostic technology detecting component defects using AI smart jig.

This research was conducted with researchers Park Seobin and Kim Taekyung as first authors. The results were published online on July 10, 2025, in the Journal of Manufacturing Systems (IF 14.2, JCR<1%), the leading international journal in the manufacturing industry, and are awaiting formal publication.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.