Applying 'High-K EMC' to Product Packaging

3.5x Higher Thermal Conductivity, 47% Lower Thermal Resistance

Solving Heat Generation in On-Device AI Implementation

"Leading the Next-Generation Mobile DRAM Market"

On August 28, SK Hynix announced that it has developed and begun supplying to customers the industry's first high-heat-dissipation mobile DRAM product using "High-K Epoxy Molding Compound (High-K EMC)" material.

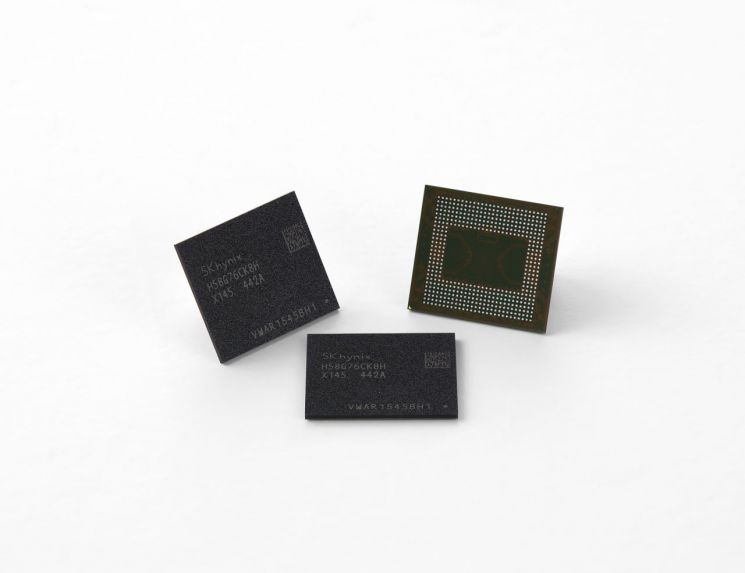

SK Hynix has become the first in the industry to apply 'High-K EMC' material to high-heat-dissipation mobile DRAM products. Photo by SK Hynix

SK Hynix has become the first in the industry to apply 'High-K EMC' material to high-heat-dissipation mobile DRAM products. Photo by SK Hynix

Epoxy Molding Compound (EMC) is an essential semiconductor post-processing material that seals and protects semiconductors from various external environments such as moisture, heat, shock, and electric charges, while also serving as a channel for heat dissipation. The material developed by SK Hynix is named "High-K" because it uses substances with a high thermal conductivity coefficient (K), thereby increasing heat conductivity. Thermal conductivity is a physical property that indicates how well a material transfers heat, referring to the amount of heat that moves through a specific material in a given period of time.

SK Hynix explained, "The heat generated during high-speed data processing for on-device artificial intelligence (AI) implementation has become a major cause of performance degradation in smartphones," and added, "With this new product, we are solving the heat dissipation issues of high-spec flagship smartphones, earning high praise from global customers."

The latest flagship smartphones are adopting the "Package on Package (PoP)" method, where DRAM is stacked on top of the mobile application processor (AP). This is a representative stacked package widely used in mobile products, in which different types of semiconductor packages are stacked vertically to achieve space efficiency, performance improvement, and flexible combinations. In particular, it offers the advantage of efficiently utilizing limited space and enhancing data processing speed. However, there is also a risk that heat generated by the mobile AP accumulates inside the DRAM, which can lead to an overall decline in smartphone performance.

To address this issue, SK Hynix focused on improving the thermal conductivity performance of EMC, the core material that encapsulates the DRAM package. As a result, the company developed a new material, "High-K EMC," by mixing alumina with the silica traditionally used in EMC. Through this, the thermal conductivity was significantly improved to 3.5 times that of the previous material, and thermal resistance in the vertical heat transfer path was reduced by 47%.

The enhanced heat dissipation performance is expected to improve smartphone performance and reduce power consumption, thereby extending battery life and overall product lifespan. As a result, interest and demand for this product are expected to increase within the mobile industry.

Lee Gyuje, Executive Vice President in charge of PKG Product Development at SK Hynix, emphasized, "This product is significant not only because it improves performance, but also because it helps alleviate the inconveniences experienced by high-performance smartphone users. Based on innovations in material technology, we will continue to solidify our technological leadership in the next-generation mobile DRAM market."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.