Reduces Shoulder Load by 60% to Assist Workers

Targeting Construction, Shipbuilding, and Agriculture; Global Expansion Planned Next Year

Hyundai Motor and Kia announced on the 9th that they have delivered the first unit of their industrial wearable robot, 'X-ble Shoulder,' to Korean Air. The handover ceremony took place the previous day at the Korean Air aircraft maintenance hangar in Jung-gu, Incheon, and was attended by Dongjin Hyun, Executive Director of the Robotics Lab at Hyundai Motor and Kia, Hyunbo Jung, Executive Director of the Aerospace Business Division at Korean Air, and others.

On the 8th, participants at the 'X-BL Shoulder' No.1 handover ceremony pose for a commemorative photo. (From left) Jongwoo Kim, Head of Robotics Business Team 1 at Hyundai Motor and Kia; Jooyoung Yoon, Head of Joint Robotics Team at Hyundai Motor and Kia; Rikun Choi, Executive Director of Robotics Business Office at Hyundai Motor and Kia; Dongjin Hyun, Executive Director of Robotics Lab at Hyundai Motor and Kia; Hyunbo Jung, Executive Director of Aerospace Business Division at Korean Air; Dohun Shin, Head of Technology Team 3 at Aerospace Business Division at Korean Air; Daeil Lee, Head of Business Planning Team at Aerospace Business Division at Korean Air. Hyundai Motor and Kia...

On the 8th, participants at the 'X-BL Shoulder' No.1 handover ceremony pose for a commemorative photo. (From left) Jongwoo Kim, Head of Robotics Business Team 1 at Hyundai Motor and Kia; Jooyoung Yoon, Head of Joint Robotics Team at Hyundai Motor and Kia; Rikun Choi, Executive Director of Robotics Business Office at Hyundai Motor and Kia; Dongjin Hyun, Executive Director of Robotics Lab at Hyundai Motor and Kia; Hyunbo Jung, Executive Director of Aerospace Business Division at Korean Air; Dohun Shin, Head of Technology Team 3 at Aerospace Business Division at Korean Air; Daeil Lee, Head of Business Planning Team at Aerospace Business Division at Korean Air. Hyundai Motor and Kia...

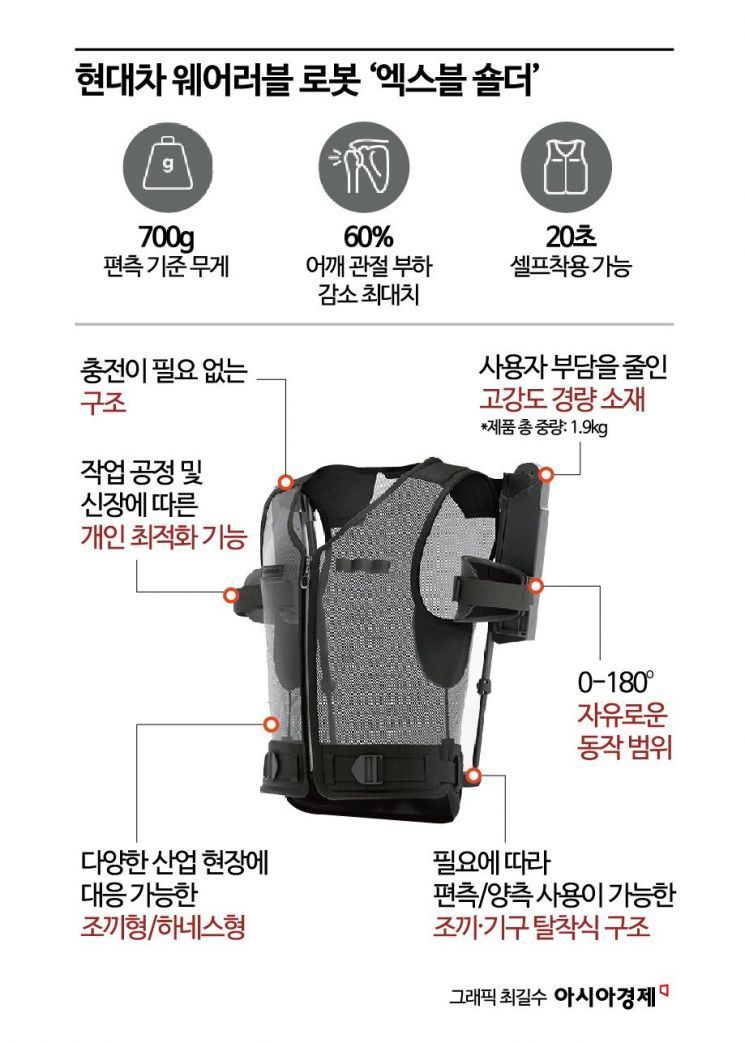

The X-ble Shoulder, developed with proprietary technology by the Hyundai Motor and Kia Robotics Lab, supports shoulder strength in overhead work environments where workers must raise their arms. It is designed to reduce the load on the shoulder joint by 60% and decrease activation of the anterior and lateral deltoid muscles by 30% during work. The device weighs approximately 1.9 kg, is lightweight, does not require charging, and offers easy and hygienic maintenance as additional advantages.

This handover ceremony marked the first delivery of the product to a contract customer since Hyundai Motor and Kia announced their commercialization plans for the X-ble Shoulder in November of last year. Korean Air, selected as the first customer, will initially deploy the X-ble Shoulder at sites within its Aerospace Business Division where it assembles and maintains military aircraft, commercial aircraft, unmanned aerial vehicles, urban air mobility (UAM) vehicles, space launch vehicles, and stealth aircraft. Because the aviation industry requires repetitive overhead work due to the large size of aircraft, the X-ble Shoulder is expected to improve worker efficiency and reduce musculoskeletal strain.

Going forward, Hyundai Motor and Kia plan to begin full-scale deliveries of the X-ble Shoulder to a variety of customers, including Hyundai Motor Group affiliates with pre-orders and domestic manufacturing companies. The company also plans to expand sales to industries such as construction, shipbuilding, and agriculture, and to enter the global market starting in 2026.

Meanwhile, since its unveiling, the X-ble Shoulder has been widely recognized worldwide for its product safety and design competitiveness. In February, it received the 'ISO 13482 certification' for safety from DNV (Der Norske Veritas), an integrated certification body for the European Union. In May, it obtained 'Machinery Directive certification.' It also won the main prize in the product category at the '2025 iF Design Award,' one of the world's top three design awards. Last year, it received an excellent design award in the robotics category at the U.S. 'Good Design Award.'

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

!["The Woman Who Threw Herself into the Water Clutching a Stolen Dior Bag"...A Grotesque Success Story That Shakes the Korean Psyche [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)