Establishing a Joint Venture with a French Recycling Company

Proactively Responding to EU Battery Recycling Regulations

Postponing the Chinese Joint Venture... Accelerating European Expansion

LG Energy Solution is partnering with Derichebourg (DBG), France's leading metal recycling and environmental services company, to establish the first Korea-Europe battery recycling joint venture (JV) in Europe. This move aims to shift the focus of LG Energy Solution's global recycling strategy toward Europe, where battery resources and demand are abundant, especially as the establishment of a joint venture with a Chinese company has been postponed amid increasing uncertainty.

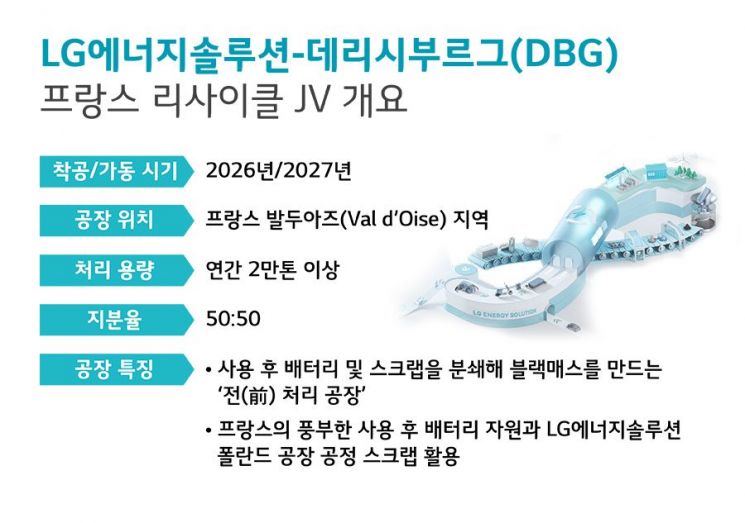

On April 29, LG Energy Solution announced that it will set up a new joint venture with DBG in Bruyeres-sur-Oise, Val-d'Oise, northern France. Construction is scheduled to begin in 2026, with full-scale operations targeted for 2027. The facility will have the capacity to process more than 20,000 tons of used batteries and scrap annually.

The new joint venture will be a preprocessing plant specializing in safely dismantling and crushing used batteries collected locally, as well as process scrap generated during battery manufacturing, to produce an intermediate product called "black mass" in powder form. Black mass is then further processed to recover key metals such as lithium, cobalt, and nickel, which are subsequently used in cathode material production and ultimately supplied to LG Energy Solution's global manufacturing facilities.

The two companies plan to secure raw materials by utilizing battery process scrap supplied from LG Energy Solution's Poland Wroclaw plant, which serves as its European production hub, as well as used batteries collected by DBG in France and neighboring regions. France accounted for 15% of all electric vehicle sales in Europe last year, making it a major market with rapidly growing battery demand. As a result, the volume of used battery resources is also expected to increase rapidly. In particular, DBG, which holds the largest market share in France's metal recycling sector and operates more than 200 collection facilities across the country, is well-positioned to effectively secure the rapidly increasing supply of used batteries in France.

With the establishment of this joint venture, LG Energy Solution is expected to accelerate its entry into the European battery recycling market. Recently, LG Energy Solution postponed plans to build a battery recycling joint venture plant with Huayou Cobalt, China's top cobalt producer. The plan had been to produce metals at the joint venture and supply them to LG Energy Solution's Nanjing battery plant. However, this decision was made due to weakened business momentum with China, which resulted from factors such as the electric vehicle chasm (a temporary stagnation in demand) and the ongoing US-China tariff war.

LG Energy Solution also plans to actively respond to the European Union's "Regulation on Batteries and Waste Batteries." Under this regulation, from 2031, the mandatory recycling rates for battery raw materials in Europe will be set at 16% for cobalt, 6% for lithium, and 6% for nickel. From 2036, these requirements will increase to 26% for cobalt, 12% for lithium, and 15% for nickel, making proactive investment essential for regulatory compliance.

Kang Changbum, Chief Strategy Officer (CSO) of LG Energy Solution, stated, "Through this collaboration, we have not only established a stable battery supply chain but also enhanced our ability to effectively respond to European battery recycling regulations. We will continue to deliver the highest customer value in the battery recycling business by leveraging our differentiated technology and production capabilities."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.