Development of a High-Performance Seawater Battery Catalyst Using Lignin and Urea

Comparable to Platinum Catalysts with Waste-Derived Materials, Published in Chem. Eng. J

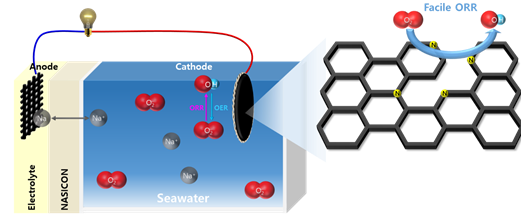

Seawater batteries are next-generation energy storage devices that store and discharge electricity using seawater.

The key to commercialization is the development of inexpensive catalytic materials, and a research team at UNIST has developed such a catalyst.

Professor Dongwook Lee's team at UNIST developed a high-performance catalyst for seawater batteries by adding urea to wood waste. The developed catalyst lowers the overpotential applied to seawater batteries and increases the reaction rate, allowing electricity to be discharged quickly.

Research team (clockwise from top right): Professor Dongwook Lee, Researcher Jinhoon Lee, Researcher Jihwan Hong (first author), Dr. Myungjin Baek. Provided by UNIST

Research team (clockwise from top right): Professor Dongwook Lee, Researcher Jinhoon Lee, Researcher Jihwan Hong (first author), Dr. Myungjin Baek. Provided by UNIST

Previously, expensive materials such as platinum were used as catalysts.

The catalyst developed by the research team is based on inexpensive lignin and urea. Lignin, which makes up 15?35% of wood, is a byproduct left over from paper manufacturing processes or biofuel production. Urea, mainly found in industrial wastewater, contains a high amount of nitrogen.

When this lignin is burned at 800°C and then reacted at the same temperature with urea, nitrogen is doped into every corner of the lignin, creating a high-performance catalyst. The nitrogen atoms that replace specific carbon atoms in lignin were analyzed to significantly reduce the energy required for discharge.

When the developed catalyst was applied to the electrodes of seawater batteries and tested for performance, it showed performance comparable to platinum catalysts. In particular, the overpotential was lower than that of the platinum (Pt/C) catalyst. The lower the overpotential, the higher the ratio of energy that can be extracted during discharge from the charged electrical energy.

The maximum power density also recorded a level close to that of the platinum catalyst (16.15 mW/cm²) at 15.76 mW/cm². Maximum power density is an indicator related to the discharge rate.

Professor Dongwook Lee of the Department of Energy and Chemical Engineering said, “This not only replaces expensive precious metal catalysts but also presents a carbon-neutral approach that maximizes the value of biomass and industrial waste,” adding, “It can also be applied to various energy storage systems such as metal-air batteries.”

This research was conducted with master's students Jihwan Hong and Inwoo Song from the Department of Energy and Chemical Engineering at UNIST as first authors, supported by the National Research Foundation of Korea (NRF) through the ‘Mid-career Researcher Support Program’ and the ‘Nano and Future Materials Core Technology Development Project.’

The research results were published in the February issue of the international journal Chemical Engineering Journal.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)