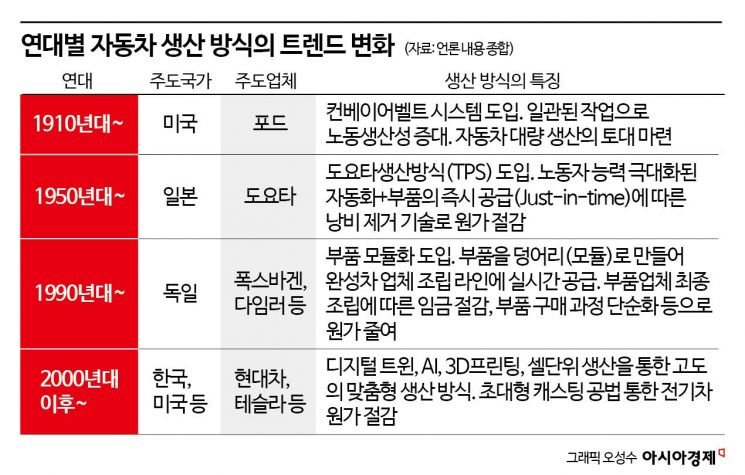

Evolution of Global Automobile Production Methods

From Conveyor Belts to Cell-Based Manufacturing

Hyundai's Modern Production System Combining the Strengths of Japan and Europe

Production Flexibility Across Diverse Models and Classes as a Key Advantage

The core competitiveness of all manufacturers ultimately lies in production know-how. No matter how excellent the technology developed is, it is meaningless if defect rates cannot be controlled during mass production. Perfectly implementing the developer's ideas to efficiently produce products of consistent quality is the key challenge of all manufacturing industries.

How Has Global Automobile Production Evolved?

The automotive industry has grown through innovations in production technology. The conveyor belt production method developed by Henry Ford in the United States laid the foundation for mass automobile production in the 1910s. By standardizing parts and subdividing each process, productivity was dramatically increased. Workers repeated the same tasks at fixed positions while products moved along the line on the conveyor belt. Ford's production method greatly contributed to the popularization of automobiles and is still widely applied across various industries today. However, Ford's method is advantageous for mass production of a few product types but is difficult to expand to diverse product lines. Additionally, even a small defect found on the production line could halt the entire line, which is a noted limitation.

The production method that emerged to complement these limitations is the Japanese-style Toyota Production System (TPS). In the 1950s, Toyota devised TPS to reduce costs and innovate productivity. The core of this method can be summarized in two main points: ▲ automation with a human touch (jidoka) ▲ just-in-time (JIT) supply to reduce inventory. First, Toyota pursued mechanical automation while maximizing the use of skilled workers' expertise. No matter how high the automation rate on the production line, mechanical defects inevitably occur. Toyota allowed workers to stop the production line themselves if mechanical defects could cause defective products. Workers would gather to solve problems and then restart the automated production line, minimizing defect rates.

Another pillar of TPS is Just-in-Time (JIT), a production technology that supplies all parts exactly when needed, allowing no waste. Finished vehicle manufacturers request parts production from suppliers only as orders come in. By producing only the quantity of products customers need at the right time, inventory can be drastically reduced. This system requires perfect synchronization between the production lines of finished vehicle manufacturers and parts suppliers. Later, when Toyota expanded to local factories in the United States, the existing JIT production method was extended to include supply chain management, research and development, and customer management. Known as the 'lean production system,' this method spread throughout the automotive industry after the 1980s.

In the 1990s, German automakers such as Volkswagen and Daimler developed the modular production method. This method involved parts suppliers delivering large modules of parts to the automaker's assembly line using the JIT method. However, the role of parts suppliers was limited to the 'assembly' function of the modules. Since parts suppliers' wages were about 20-30% lower than those of European automakers at the time, outsourcing parts procurement and assembly to external companies significantly reduced costs.

In the mid-1990s, Japanese and Korean automakers actively adopted the European modular method, adapting it to their own circumstances. Modularization is a double-edged sword for automakers. Outsourcing to parts suppliers simplifies parts and increases productivity, as well as reduces costs through labor savings. However, the stronger the parts suppliers' influence, the more the automaker's position can be shaken. If parts suppliers are involved in development and supply modules, automakers may fear losing technological leadership. Therefore, Japanese companies such as Toyota, Honda, and Nissan have promoted modularization centered on affiliated key parts suppliers. Hyundai Motor Group has also expanded its modular business by strengthening vertical integration centered on Hyundai Mobis.

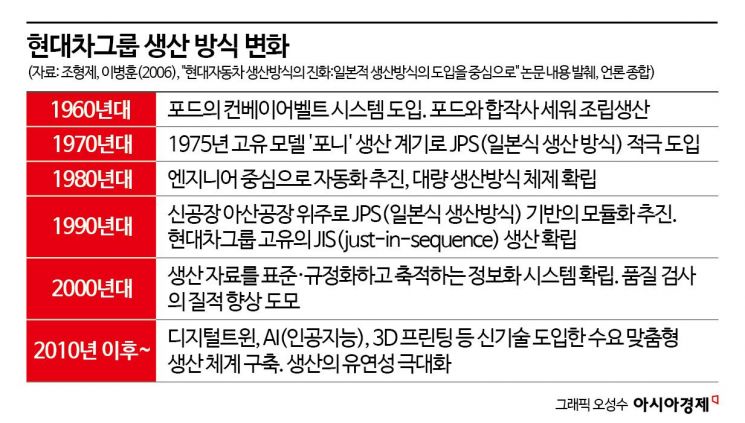

Modern Production System (HPS) Combining the Best of Japan and Europe

Hyundai Motor Group borrowed the strengths of Japanese (JIT) and European (modularization) production methods to create a new Hyundai Production System (HPS) tailored to Korea's production environment. HPS is a core competency that enables Hyundai's greatest strength: 'production flexibility.' Hyundai established the JIS (just-in-sequence) method, which adds production and assembly sequencing of vehicle models to Japan's JIT (just-in-time parts supply) method. Parts suppliers and automakers share production schedules in real time, supplying modules at the exact time and sequence required.

Hyundai Motor Group introduced the Japanese JIT concept while actively pursuing modularization. Japanese companies also promoted modularization mainly through affiliated parts suppliers but were passive and automaker-centered. In contrast, Hyundai's modularization, centered on Hyundai Mobis, involves a much more active role for parts suppliers. After the late 1990s foreign exchange crisis, major Hyundai parts suppliers such as Mando Machinery, Halla Climate Control, and Deokyang Industry were acquired by foreign companies, which emphasized the importance of a reliable affiliate like Hyundai Mobis.

Another production strength of Hyundai is mixed production beyond vehicle classes (body sizes). Even today, many American and European automakers divide their global factories by vehicle class. For example, U.S. factories mainly produce large vehicles, while European or Korean factories focus on small vehicles, planning production according to local labor costs and capital procurement conditions. In contrast, Hyundai Motor Group has the advantage of mixed production of various vehicle models beyond vehicle classes at all its global factories. This means that a single line can produce a wide range of models from small to large vehicles. Moreover, Hyundai and Kia are known among global brands for offering many diverse specifications (options), made possible by an active modularization policy based on parts informatization.

Established in 1996, Hyundai Motor Asan Plant served as a test bed for Hyundai Motor Group's modularization business. Hyundai built the Hyundai Mobis Asan Plant just 25 minutes by truck from the finished vehicle plant to enable real-time module delivery. According to the thesis 'Changes in the Nature of Labor Unions Due to Changes in Production Methods' by Lee Hong-il (2008), the modularization rate of the Starex launched in 1997 was about 12.5%, but the modularization rate of the Grand Starex launched in 2007 rose to 42%. With parts commonality achieved through shared platforms, it is estimated that the current modularization rate is much higher.

Another point that differentiates Hyundai Production System (HPS) from the Japanese method is how labor is utilized. Toyota emphasized maximizing labor with a 'human touch' while pursuing automation. Even when using machines, human hands are needed, and the ultimate goal was to create workers who 'think while working.' The concept is to fill in defects or flexibility needs that machines might miss with the experience of skilled workers.

Hyundai supplemented some defects occurring during automation with informatization and management systems operated by production engineers. Rather than expecting active roles from on-site workers, Hyundai enhanced the technical roles of middle engineers to keep the site running. Experts explain that this characteristic of HPS stems from Hyundai's 'adversarial labor-management relations.' Kim Jin-baek and Lee Nam-seok (2017) in their study 'Comparison of Hyundai Motor and European/Japanese Modular Production Methods and Their Impact on Electronic Trade Environment' stated, "Due to adversarial labor relations and a weak domestic parts industry base, Hyundai found it difficult to pursue the Japanese production method as is," and "As an alternative, Hyundai developed a production method relying on automation and information technology while depending on internal affiliates."

Since its establishment in 1987, the Hyundai Motor labor union has become one of South Korea's most militant unions. When the 1997 foreign exchange crisis hit, Hyundai faced waves of layoffs, and the union's 'anti-layoff struggle' intensified, pushing labor-management relations to the extreme. This period coincided with Hyundai's active overseas expansion, including the completion of its first overseas production plant in Turkey in 1997. Hyundai chose to reduce dependence on highly skilled workers by promoting automation using middle engineers and informatization through IT investment.

Paradoxically, this systemization became a catalyst for Hyundai's active overseas plant expansion after the 2000s. Lacking skilled workers and a domestic parts industry base, Hyundai pursued engineer-centered automation and informatization and expanded overseas by jointly entering with parts suppliers through automaker-led modularization. The Alabama plant in the United States, established in 2005, achieved rapid production yield within 2-3 years despite a low proportion of skilled workers, thanks to these HPS characteristics.

How Will Hyundai Make Cars 10 Years from Now?

What changes will Hyundai's production methods undergo in the next 10 years? The Hyundai Motor Group Innovation Center Singapore (HMGICS), a representative innovation hub of Hyundai Motor Group, provides insight into future directions. Established in November 2023 in the Jurong Innovation District of Singapore, HMGICS comprises not only smart manufacturing facilities but also brand experience spaces, vehicle test drives, and test tracks.

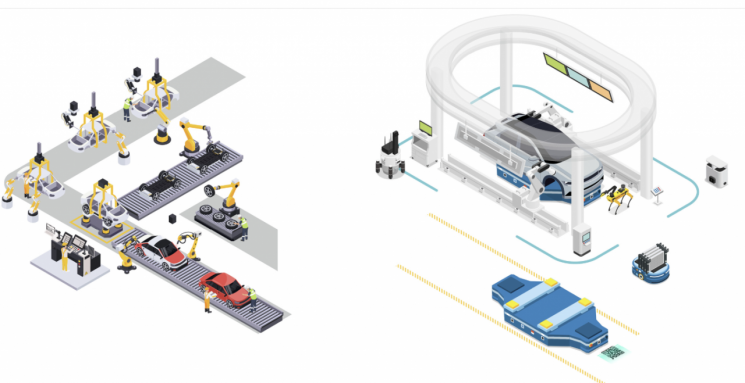

The core facility, the Smart Manufacturing Technology Center, specializes in small-volume, multi-model production using advanced technologies. Instead of the traditional conveyor belt, vehicles are produced in oval-shaped 'cells.' Workers operate as a team with robots within a single cell. Once all necessary parts are installed, an Automated Guided Vehicle (AGV) moves the vehicle to the next cell. All processes flow seamlessly according to the input vehicle model, specifications, and parts assembly sequence. Autonomous Mobile Robots (AMRs) deliver the required parts to each cell unmanned.

The advantage of cell-based production is the ease of process improvement or change. Traditional conveyor belt systems have fixed equipment and processes tailored to specific vehicle models. Therefore, changes require large-scale investments whenever a new model is introduced. However, with cell-based production, each cell can input different equipment and process sequences for various models and specifications, allowing easy changes to production plans. However, labor required for processes actually increases. To compensate, Hyundai Motor Group plans to actively utilize various industrial robots.

Another notable point is that all processes are data-driven. Hyundai Motor Group has already established various data-based systems to prevent incorrect parts installation, such as specification instruction monitors, barcode systems, automatic parts sorting systems, and parts inspection systems using laser vision. In future Hyundai Motor Group factories, everything from equipment to parts movement and work status will be recorded and managed as data.

Ioniq 5, produced at the cell level at Hyundai Motor Group Singapore Global Innovation Center (HMGIS). Photo by Hyundai Motor Company

Ioniq 5, produced at the cell level at Hyundai Motor Group Singapore Global Innovation Center (HMGIS). Photo by Hyundai Motor Company

At HMGICS, numerous movements of different robots, machines, and workers in various cells are digitized. Additionally, a 'digital twin' technology creates a virtual twin factory to monitor the real factory, implemented based on data. Unlike traditional CCTV, which has blind spots due to camera limitations, the digital twin monitoring system has no blind spots because it monitors based on data assigned to all production equipment, processes, and components within the factory. Hyundai Motor Group has also built a 5G network system to share the vast amount of data accumulated from factory operations in real time. The data-driven smart factory operation solutions tested at HMGICS are planned to be expanded to Hyundai Motor Group's factories worldwide. Ultimately, the goal is to transform all factories into smart factories and create data-driven factories that operate automatically based solely on data.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)