Research Team of Professor Kim Kyung-jin at Kyungpook National University, Zien, and CJ CheilJedang Industry-Academic Collaboration Team

Develop World's Highest Performance PET Plastic Degrading Enzyme

Enabling Eco-Friendly Plastic Recycling Based on Advanced Bio

Published in Prestigious Journal 'Science'

A world-class bio-catalyst, an enzyme developed with domestic technology, enables the recycling of waste PET plastics without chemical contamination or quality degradation. It is expected to contribute to establishing a leading position for domestic companies in the field of plastic recycling in the future.

Photo of a transparent PET bottle newly synthesized using a world-class bio-catalyst from C-grade composite flakes mixed with colored flakes and aluminum materials. Photo by Ministry of Science and ICT

Photo of a transparent PET bottle newly synthesized using a world-class bio-catalyst from C-grade composite flakes mixed with colored flakes and aluminum materials. Photo by Ministry of Science and ICT

The Ministry of Science and ICT announced on the 3rd that Professor Kim Kyung-jin of Kyungpook National University (also CEO of Zyen) and the CJ CheilJedang research team have developed the world's highest-performance bio-catalyst (PET depolymerase, PETase) that decomposes PET (polyethylene terephthalate) plastic under industrial conditions.

This research achievement was published in the international academic journal Science under the title "Landscape profiling of PET depolymerases using a natural sequence cluster framework." Dr. Seo Ho-gyun (Kyungpook National University Microbial Research Institute), Dr. Hong Hwa-seok (CJ CheilJedang Bio Research Institute), and doctoral candidate Park Ji-young (Kyungpook National University) participated as first authors.

PET is used not only for PET bottles but also for clothing, seat belts, take-out cups, vehicle mats, and more. Currently, most PET is recycled through mechanical recycling (MR). According to the Ministry of Environment, the recycling rate of transparent PET bottles in Korea reached 77% in 2021, but most of it is used for low- to mid-grade applications such as staple fibers (nonwoven fabric) (73%), while high-grade uses such as sheets account for only 15%.

This is based on the problem of low quality of recycled plastics. The mechanical recycling method mainly used for waste plastics currently results in low quality, leading to incineration or landfill, which causes environmental pollution. Chemical recycling also has issues with raw material contamination and environmental impact.

On the other hand, biological recycling using bio-catalysts selectively reacts with PET and produces pure reaction products, resulting in less environmental burden and superior quality of recycled materials.

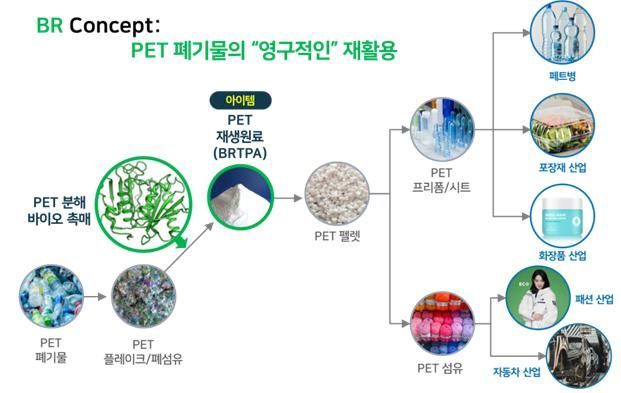

Flowchart of the process in which PET waste is transformed into products. The PET-degrading biocatalyst breaks down the waste to produce recycled raw materials, creating a link that supplies recycled raw materials to the existing PET plastic industry, enabling endless recycling. Photo by Ministry of Science and ICT

Flowchart of the process in which PET waste is transformed into products. The PET-degrading biocatalyst breaks down the waste to produce recycled raw materials, creating a link that supplies recycled raw materials to the existing PET plastic industry, enabling endless recycling. Photo by Ministry of Science and ICT

The research team approached this with the concept of biocatalytic recycling (BR). Just as PET does not decompose in the environment, finding a bio-catalyst that decomposes PET is almost impossible. The team developed a new approach to predict the activity of bio-catalysts existing in nature.

The team drew a landscape of clusters of similar bio-catalysts hidden in nature to predict their potential and succeeded in discovering a new bio-catalyst called 'Kubu-P.' Then, using enzyme engineering technology, they developed a more powerful 'KubuM12.' KubuM12 demonstrated the ability to decompose 45% of 1 kg of PET within 1 hour and over 90% within 8 hours using only 0.58 g of the enzyme.

Professor Kim Kyung-jin stated, "Biological recycling through bio-catalysts is a revolutionary technology that enables permanent recycling even of contaminated plastics that cannot be recycled. We expect innovations applying bio-catalysts to various chemical industries in the future."

The Ministry of Science and ICT and the research team anticipate that this will open the door to the commercialization of domestic white biotechnology (White biotechnology, bio-technology applied to the chemical industry) research beyond the petrochemical industry.

The research team has already produced biologically recycled PET bottles for the first time in Korea from C-grade flake raw materials mixed with colored chips and aluminum using KubuM12. Additionally, Zyen is expanding the industrial application of bio-catalysts by starting research on fiber recycling in collaboration with companies such as Hyosung TNC.

This research was conducted with the support of the Ministry of Science and ICT’s Bio and Medical Technology Development Program.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![From Hostess to Organ Seller to High Society... The Grotesque Scam of a "Human Counterfeit" Shaking the Korean Psyche [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)