KRICT Develops World's First Technology to Produce Semiconductors and Displays with Water, Free of Toxicity

Researchers at the High-Performance Polymer Research Center who developed waterborne polyimide manufacturing technology are posing for a commemorative photo. Photo by Korea Research Institute of Chemical Technology

Researchers at the High-Performance Polymer Research Center who developed waterborne polyimide manufacturing technology are posing for a commemorative photo. Photo by Korea Research Institute of Chemical Technology

As environmental regulations tighten and demand for eco-friendly materials increases, a domestic research team has developed the world's first polyimide manufacturing technology using water instead of toxic organic solvents. Korean battery companies have rushed to sign technology transfer agreements to secure this technology.

On the 16th, the research team led by Drs. Won Jong-chan, Kim Yun-ho, and Park Jong-min at the Korea Research Institute of Chemical Technology announced that they successfully implemented an eco-friendly process that polymerizes polyimides with high-temperature durability and high strength using water as a solvent.

Polyimide is a polymer material with excellent heat resistance, mechanical strength, and chemical stability. It is widely used in advanced industries such as displays, semiconductors, and aerospace. In particular, due to the increasing demand for semiconductors and electronic devices, the global polyimide market has recorded an average annual growth rate of over 7%.

However, conventional polyimide polymerization requires the use of toxic organic solvents such as NMP, DMAc, and DMF, which pose environmental pollution and health hazards. Additionally, the polymerization process temperature is above 350 degrees Celsius, resulting in high energy consumption and production costs.

To address these issues, the research team developed a water-borne polymerization process. This opened the way to synthesize high-performance polyimides in an eco-friendly manner by replacing the existing organic solvent process.

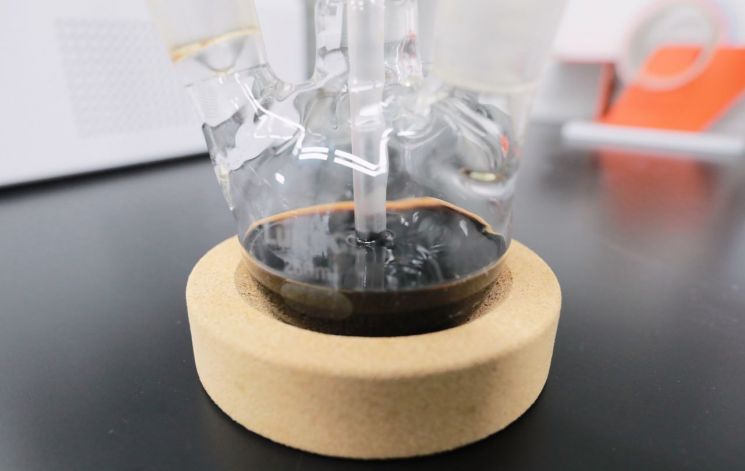

Aqueous polyimide solution after polymerization completion. Photo by Korea Research Institute of Chemical Technology

Aqueous polyimide solution after polymerization completion. Photo by Korea Research Institute of Chemical Technology

The developed technology lowered the process temperature to below 250 degrees Celsius compared to the conventional method while achieving physical properties equivalent to those of representative polyimide products already commercialized using the traditional organic solvent method.

Generally, conventional polyimide material manufacturing processes use organic solvents with high boiling points and strong toxicity. In contrast, this technology uses water as the reaction solvent, significantly reducing the cost of synthetic materials to less than 10%. Moreover, it eliminates the need for costly distillation recovery facilities required for handling toxic organic solvents.

Electricity consumption required for the process can also be greatly reduced. According to the research team, while the conventional organic solvent-based process requires high temperatures above 350 degrees Celsius, the new low-temperature process at 250 degrees Celsius, which is more than 100 degrees lower, can reduce electricity usage by over 30%.

The Korea Research Institute of Chemical Technology explained that this technology enhances the commercialization potential of polyimide materials by presenting an eco-friendly process that replaces existing toxic organic solvents.

Companies such as GL Chem have also signed technology transfer agreements with the Chemical Research Institute. This creates a virtuous cycle where technology developed by government-funded research institutes using government investment is applied to private companies' battery anode binders and insulating materials. The research team plans to expand into high value-added industries through various applied studies such as battery binders, insulating coatings, and 3D printing materials.

Drs. Won Jong-chan and Kim Yun-ho stated, "This research is an innovative eco-friendly process that satisfies both environmental and economic aspects. We plan to continue research to strengthen the long-term development and global competitiveness of not only polyimide materials but also high-performance polymer materials."

The research results were published as the cover paper in the October issue of ACS Sustainable Chemistry & Engineering (IF: 8.3) and in the July issue of the Chemical Engineering Journal (IF: 13.4), respectively.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)