The U.S. government has decided to provide a production subsidy of $75 million (approximately 106.4 billion KRW) under the CHIPS and Science Act (CSA) to Absolix, an investment company in SKC's semiconductor glass substrate business.

According to the U.S. Department of Commerce on the 5th (local time), Absolix finalized a contract with the authorities on the same day to receive a $75 million production subsidy under the semiconductor law. This was finalized after on-site due diligence following the preliminary memorandum of transaction (PMT) signed in May. SKC is the first semiconductor materials, parts, and equipment (MPE) company to receive a production subsidy under the semiconductor law.

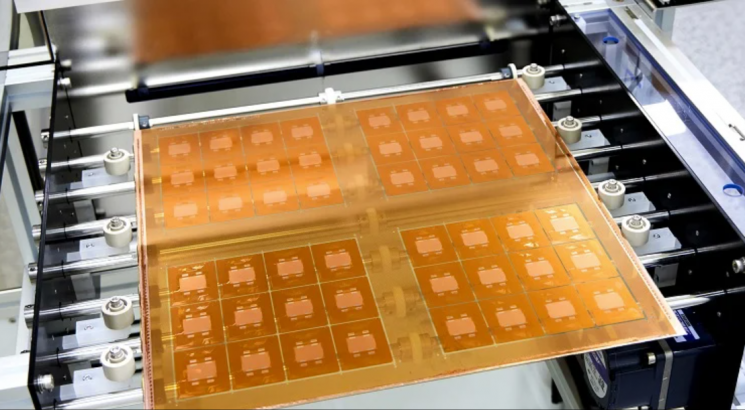

Absolix secured this subsidy by investing about $300 million to complete its first glass substrate factory in Covington, Georgia, USA. The subsidy ratio relative to the investment amount is about 22%. Absolix’s Covington Glass Substrate Plant 1, currently producing prototypes, is the world's first mass production plant for glass substrates.

Earlier, on the 21st of last month, Absolix was also selected as a recipient of a $100 million grant from the National Advanced Packaging Manufacturing Program (NAPMP) by the U.S. government. Absolix formed a consortium with over 30 partners including global big tech companies, academia, and non-profit organizations, becoming the first to receive R&D subsidies in the glass substrate field.

Since announcing its glass substrate business in 2021, SKC has established Absolix and steadily prepared for commercialization. It is actively engaged in creating an industrial ecosystem through collaboration with global companies and academia. However, glass substrates, the next-generation semiconductor material, are still in the pre-commercial development stage and are called the "dream substrate" in the semiconductor industry.

Compared to existing silicon interposer substrates, glass substrates are known to be 40% faster in speed and can reduce power consumption, package thickness, and production time by more than half, making them a "game changer" for processing large volumes of data at high speed, such as in artificial intelligence (AI).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.