Jeon Gi-yeon, World's First Development of High-Dispersibility Carbon Nanotube Powder Manufacturing Technology

The Korea Electrotechnology Research Institute (Director Namkyun Kim) announced on the 25th that Dr. Han Jungtak's team at the Nano Convergence Research Center has developed the world's first 'high-dispersibility carbon nanotube (CNT) powder manufacturing technology' that can be easily applied to the eco-friendly dry process of next-generation secondary batteries.

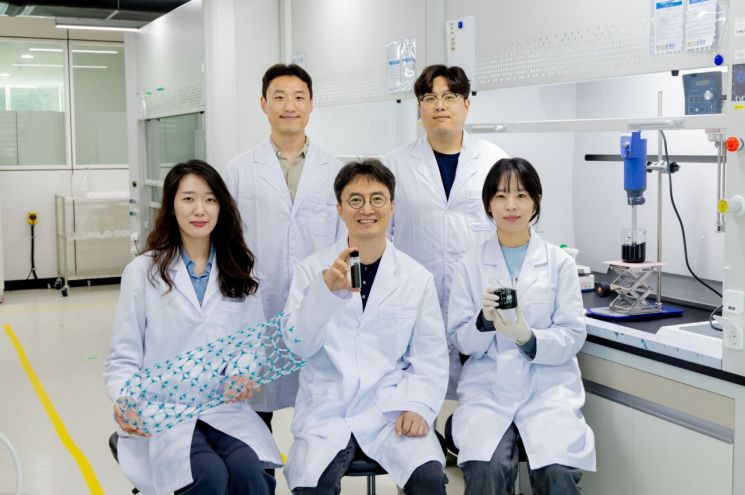

The Korea Electrotechnology Research Institute's research team (Team Leader: Kim Minsoo) has developed a carbon nanotube (CNT)-based sensor that shows high sensitivity to gases. Photo by Korea Electrotechnology Research Institute

The Korea Electrotechnology Research Institute's research team (Team Leader: Kim Minsoo) has developed a carbon nanotube (CNT)-based sensor that shows high sensitivity to gases. Photo by Korea Electrotechnology Research Institute

CNT is a new material with a strength 100 times that of steel and electrical conductivity comparable to copper. It consists of carbon atoms connected in hexagonal rings forming a long cylindrical shape. Compared to carbon black, which is used as a conductive material in conventional secondary batteries, CNT is a flexible and electrically superior one-dimensional nanomaterial.

When CNT is used as a conductive material in next-generation secondary batteries, even a small amount of addition can significantly increase energy density. However, CNT has a very strong tendency to agglomerate, forming tangled structures, and does not mix uniformly with other battery materials such as binders and active materials. Especially in the dry process, CNT must be uniformly mixed with other materials without solvents. This has been considered one of the challenges the battery industry must overcome.

The achievement by Dr. Han Jungtak's team is the development of a technology that produces CNT in powder form to minimize agglomeration and easily disperse it with active materials or binder materials in the dry process. Through years of research, the team succeeded in controlling CNTs so that they do not clump together and maintain a dispersed state even in powder form.

The Korea Electrotechnology Research Institute has developed a high-efficiency power semiconductor device called the Silicon Carbide (SiC) MOSFET, which is expected to significantly improve power conversion efficiency in electric vehicles. Photo by Korea Electrotechnology Research Institute

The Korea Electrotechnology Research Institute has developed a high-efficiency power semiconductor device called the Silicon Carbide (SiC) MOSFET, which is expected to significantly improve power conversion efficiency in electric vehicles. Photo by Korea Electrotechnology Research Institute

This breakthrough opens the way to manufacture high-capacity batteries using conductive materials made from long one-dimensional CNTs even in the demanding dry process. Well-dispersed, highly conductive CNTs without solvent use electrically connect other internal materials effectively, greatly contributing to enhancing the performance of next-generation secondary batteries.

Dr. Han Jungtak of the Korea Electrotechnology Research Institute stated, "The dry process is eco-friendly as it does not use toxic solvents, does not require solvent recovery, simplifies the process, and reduces production costs, attracting attention from global electric vehicle manufacturers." He added, "We are the first in the world to effectively disperse CNTs to make conductive materials in the dry process, which will greatly help secure a technological lead in next-generation secondary battery technology."

The Korea Electrotechnology Research Institute has completed domestic patent applications for this achievement and is conducting various verifications, including applying the 'high-dispersibility CNT powder manufacturing technology' to thick, high-capacity thick-film anodes and cathodes. The institute expects this achievement to attract significant interest from related industries requiring dry processes for next-generation batteries such as lithium-sulfur batteries and all-solid-state batteries, and plans to identify demand companies and proceed with technology transfer. This research was supported by the Creative Convergence Research Project of the National Research Council of Science & Technology.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)