A foundational technology that simultaneously enhances the energy storage and load-bearing performance of structural batteries has been developed domestically. Structural batteries are utilized in eco-friendly energy-based industries such as automobiles, mobility, and aerospace.

KAIST announced on the 19th that Professor Seongsu Kim's research team from the Department of Mechanical Engineering has developed a multifunctional carbon fiber composite structural battery.

(From left) Bae Sang-yoon, Ph.D. candidate, Department of Mechanical Engineering, KAIST; Professor Kim Sung-soo; Lim Soo-hyun, Ph.D. candidate. Provided by KAIST

(From left) Bae Sang-yoon, Ph.D. candidate, Department of Mechanical Engineering, KAIST; Professor Kim Sung-soo; Lim Soo-hyun, Ph.D. candidate. Provided by KAIST

The multifunctional composite structural battery is significant in that each material constituting the composite can serve both as a load-bearing structure and as an energy storage component.

While existing structural battery technologies faced conflicts between these two functions, making it difficult to enhance performance simultaneously, the structural battery developed by the research team overcame these limitations.

Early structural batteries involved inserting commercial lithium-ion cells into laminated composites, resulting in low integration of mechanical and electrochemical performance, which complicated material processing, assembly, and design optimization, thus hindering commercialization.

Inspired by this, the research team approached the development of a high-density multifunctional carbon fiber composite structural battery from the perspective of an ‘energy-storing composite material,’ focusing on interfacial and curing characteristics critical in conventional composite design to maximize the multifunctionality of the structural battery.

During this process, the team analyzed the curing mechanism of epoxy resin with high mechanical properties and solid polymer electrolytes based on ionic liquids and carbonate electrolytes, which harden during curing, and optimized the curing process by controlling appropriate temperature and pressure conditions.

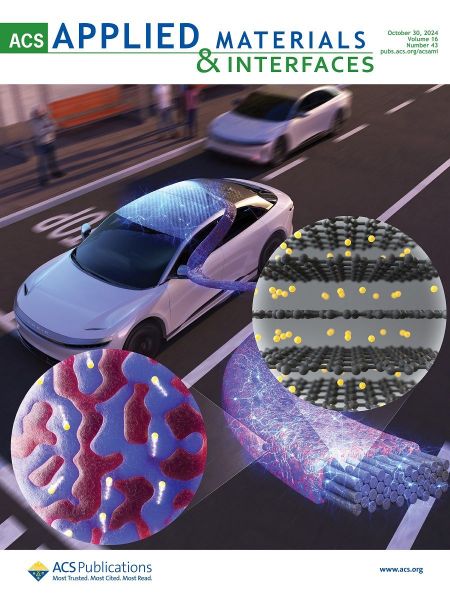

They also succeeded in increasing the volume fraction of carbon fibers, which act as electrodes and current collectors within the structural battery, by more than 160% compared to batteries using conventional carbon fibers, by compressing and molding the composite material under vacuum conditions.

This significantly increased the contact area between the electrodes and electrolyte, driving the production of a high-density structural battery with improved electrochemical performance.

The research team also effectively controlled bubbles that could form inside the structural battery during the curing process, simultaneously enhancing the mechanical properties of the structural battery.

Professor Seongsu Kim, the lead researcher, stated, “Our team proposed a framework for designing solid polymer electrolytes, the core material of high-rigidity ultrathin structural batteries, from both material and structural perspectives. The structural battery based on the materials developed by our team will serve as a foundational technology contributing to the development of ‘next-generation multifunctional energy storage applications’ that dramatically extend operating times when embedded and charged inside structures such as automobiles, drones, aircraft, and robots.”

Meanwhile, this research was conducted with support from the Korea Research Foundation’s Mid-career Research Program and the National Semiconductor Research Laboratory Development Project. The research paper, with Mohamad Raja, a master’s student in KAIST’s Department of Mechanical Engineering, as the first author, was published on the 10th of last month in the internationally renowned journal ‘ACS Applied Materials & Interfaces.’ Notably, the paper was recognized for its excellence and selected as a cover article for the journal.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)