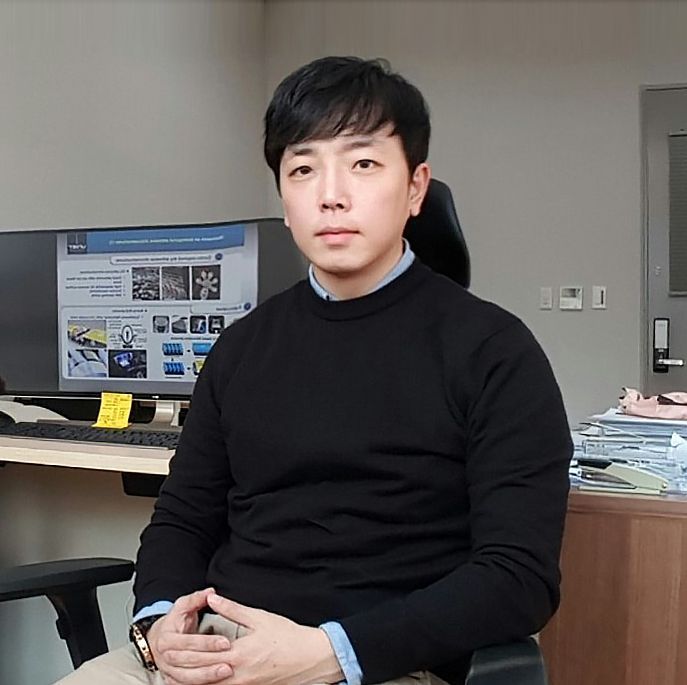

Professor Jeonghoon's Team Develops Skin Patch with Strong Adhesion and Detachment for Body Movements

Applications in Healthcare Monitoring, Transdermal Drug Delivery Devices... Published in Adv. Mater.

A super-strong adhesive patch that sticks well even on rough skin textures and during intense physical movements, yet can be removed without irritation when desired, has been developed.

The secret lies in the adhesive power of barnacles and the strong yet flexible armor structure of the armadillo.

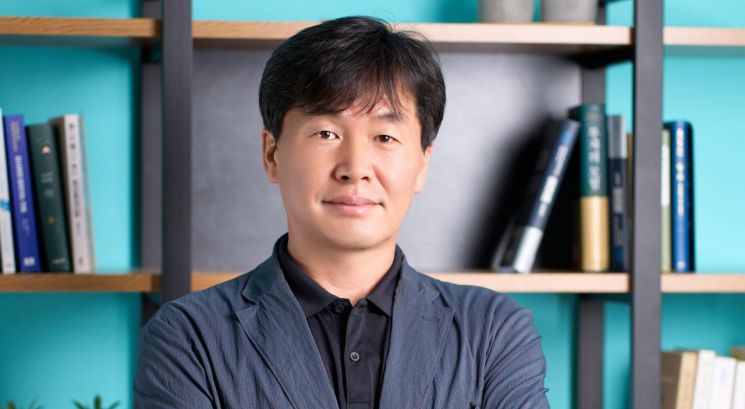

The research team led by Professor Jeong Hoon-ui from the Department of Mechanical Engineering at UNIST (President Jong-rae Park), in collaboration with Professor Kim Jae-jun’s team from the Department of Electrical and Electronic Engineering and the Ecological New Technology Team at the National Institute of Ecology, developed a skin patch (motion-adaptive tessellation patch) that excels in adhesion, removability, and elasticity. This technology is attracting attention as it could aid the commercialization of wearable electronic devices such as healthcare monitoring and transdermal drug delivery.

The research team developed this adhesive patch by arranging shape-memory polymers that mimic the characteristics of barnacle adhesive proteins in a pattern inspired by the armadillo’s armor structure.

Barnacle adhesive proteins have a property where their stiffness changes, allowing them to adhere closely to uneven rock surfaces. The soft adhesive proteins fill the rough rock surface meticulously and then harden to firmly attach to the rock.

The shape-memory polymers, which imitate this principle, can adhere to rough skin surfaces and can be easily removed without irritation by controlling the temperature when desired. By simply changing the temperature, the patch can be attached and detached multiple times.

Additionally, the arrangement modeled after the armadillo’s armor structure enhances elasticity and flexibility, preventing the patch from falling off or being damaged even during intense physical movements.

The armadillo armor has a ‘tessellation’ structure where soft collagen fills the spaces between hard bone plates, making it strong enough to deflect bullets while still being able to curl up. The research team mimicked this structure by filling the gaps between shape-memory polymer pieces with elastic polymers, maximizing adhesion.

Professor Jeong Hoon-ui explained, “Existing body-attached devices are vulnerable to deformation and repetitive stress caused by movement, often causing skin irritation and discomfort during long-term wear. Through this research, we have developed an innovative adhesive technology that solves all these issues.”

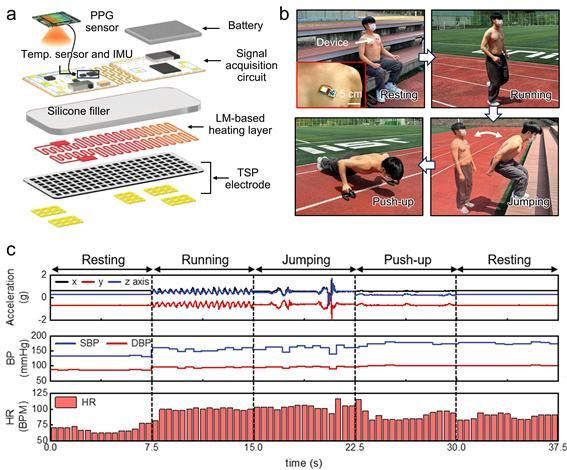

Wearable electronic devices made with this patch maintained adhesion even during intense movements such as running or climbing stairs, successfully measuring the wearer’s heart rate and blood pressure.

Professor Kim Jae-jun said, “To embed batteries and sensors in devices and obtain high-quality biosignals, adhesion must be maintained even during intense movements. This technology overcomes the limitations of existing technologies that were restricted by movement and will contribute to the development of wearable devices usable on various body parts.” He added, “We plan to prepare for technology transfer and startup based on this technology in the future.”

The research results were published online on October 20 in the prestigious materials science journal Advanced Materials and are scheduled for formal publication soon.

The research was supported by the Ministry of Science and ICT, the Ministry of Trade, Industry and Energy, and the National Institute of Ecology.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)