A technology capable of precisely diagnosing batteries with a small amount of current has been developed. This technology is expected to enhance the long-term stability and efficiency of electric vehicle batteries.

KAIST announced on the 17th that a joint research team led by Professors Kwon Kyungha and Lee Sangguk from the Department of Electrical Engineering has developed an Electrochemical Impedance Spectroscopy (EIS) technology that can be used to improve the stability and performance of large-capacity electric vehicle batteries.

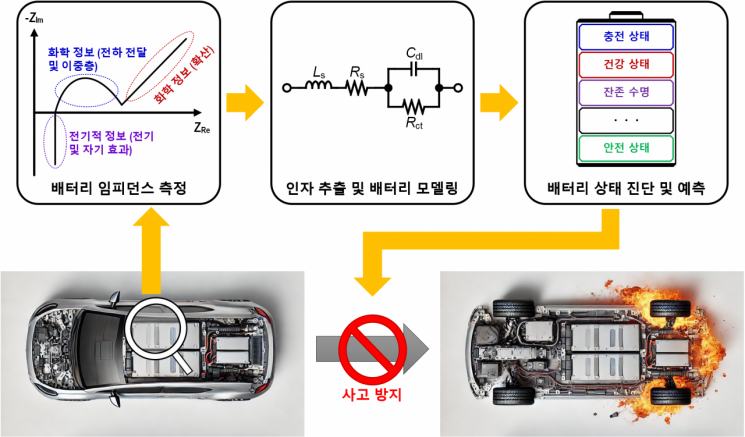

Flowchart for Electric Vehicle Battery Impedance Measurement for Condition Diagnosis and Accident Prevention. Provided by KAIST

Flowchart for Electric Vehicle Battery Impedance Measurement for Condition Diagnosis and Accident Prevention. Provided by KAIST

The EIS technology is a tool that measures the magnitude and changes of battery impedance (the factors resisting current flow inside the battery) to evaluate battery efficiency and loss. It enables the analysis of thermal characteristics, chemical and physical changes, lifespan prediction, and identification of failure causes in batteries.

However, existing EIS equipment faced difficulties due to sensitivity and precision limitations, as applying current disturbances of several amperes (A) to the battery increased the risk of electrical stress leading to failure or fire hazards.

The joint research team developed a low-current EIS system to overcome these limitations. This system can precisely measure battery impedance with a low (10mA) current disturbance, minimizing thermal effects and safety issues during measurement.

Another strength is its design, which minimizes bulky and costly components, making it easy to install in vehicles.

The joint research team also demonstrated that the low-current EIS system effectively captures the electrochemical characteristics of electric vehicle batteries across various temperatures and state-of-charge (SOC) levels representing remaining battery capacity.

Professor Kwon stated, "The low-current EIS system can be easily integrated into electric vehicle battery management systems (BMS), significantly reducing cost and complexity compared to conventional high-current EIS methods while demonstrating high measurement precision. We expect it to contribute not only to electric vehicles but also to battery diagnosis and performance enhancement in energy storage systems (ESS) in the future."

Meanwhile, this research was conducted with support from the National Research Foundation of Korea’s Basic Research Program, the Korea Institute for Advancement of Technology’s Next-Generation Intelligent Semiconductor Technology Development Program, and the Institute for Information & Communications Technology Planning & Evaluation’s AI Semiconductor Graduate School Program.

The research results were published on the 5th of last month in the internationally renowned journal ‘IEEE Transactions on Industrial Electronics.’

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![From Bar Hostess to Organ Seller to High Society... The Grotesque Con of a "Human Counterfeit" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)