A soft artificial muscle that is strong enough to withstand being run over by a car and has elasticity like a rubber band has been developed.

On the 15th, the Korea Research Foundation announced that a research team led by Professor Jeong Hoon-ui from the Department of Mechanical Engineering at Ulsan National Institute of Science and Technology (UNIST) developed a magnetic composite artificial muscle with a stiffness change rate increased up to 2700 times.

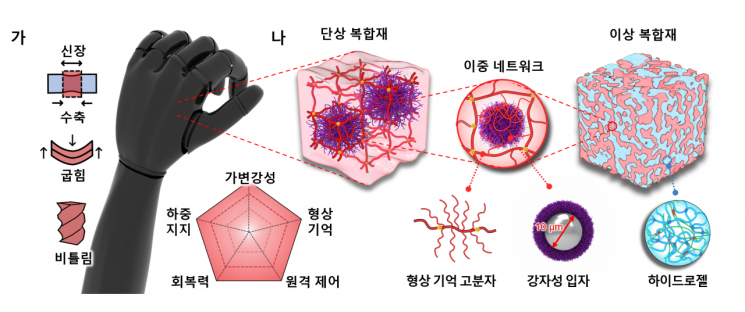

Schematic diagram of self-magnetic composite artificial muscle and material. Provided by the National Research Foundation of Korea

Schematic diagram of self-magnetic composite artificial muscle and material. Provided by the National Research Foundation of Korea

The research team developed this artificial muscle by combining ferromagnetic particles with conventional shape memory polymers.

Shape memory polymers are a type of variable stiffness material that can deform into a specific shape in response to external stimuli such as temperature, electricity, or light, and return to their original shape once the stimulus is removed. Ferromagnetic particles strongly respond to magnetic fields and can maintain a magnetized state; iron and nickel are examples of such particles.

Artificial muscles are mainly used in applications such as robots, wearable devices, and biomedical devices, and are recognized as core technology.

However, conventional artificial muscles made from soft polymer materials allowed flexible movement without complex control, but due to their low stiffness, they had difficulty lifting heavy objects and showed limitations in precise control because of unnecessary vibrations.

To address this, variable stiffness materials that can change stiffness from a hard state to a soft state have been used, but the limited range of stiffness adjustment and insufficient mechanical performance have remained challenges to overcome.

In contrast, the research team succeeded in increasing load-bearing capacity and elasticity by developing an artificial muscle combining shape memory polymers and ferromagnetic particles.

Ferromagnetic particles with special surface treatment form physical entanglements with the shape memory polymer, enhancing the mechanical properties of the composite while enabling the external magnetic field to respond quickly and efficiently.

The artificial muscle developed by the research team based on this principle can increase stiffness up to 2700 times. In the soft state, it can stretch more than 8 times its original length, and in the hard state, its load-bearing capacity can improve tensile stress up to 1000 times and compressive stress up to 3690 times its own weight.

In terms of operational performance as an actuator controlling movement, it demonstrated excellent energy efficiency of 90.9%.

To reduce unnecessary vibrations occurring in conventional soft actuators, the research team fabricated the artificial muscle with a double-layer structure by adding a hydrogel layer, enabling precise control even during rapid operation.

Professor Jeong said, “We expect that the soft artificial muscle developed through this research will be applied in various fields based on its excellent mechanical properties and driving performance.”

Meanwhile, the research was conducted with support from the Ministry of Science and ICT and the Korea Research Foundation’s mid-career research program. The research results were published online on September 10 in the international journal Nature Communications.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.