Busan National University, Gwangju Institute of Science and Technology, and Nano Convergence Technology Institute Joint Research Published in 'Optica' Journal

Successful Development of Humidity Sensor Based on Nanostructure with High Reactivity and High Color Reproduction Structural Color

A sensor capable of accurately measuring humidity changes in real time using only color, without electricity or batteries, has been developed.

This sensor was made using a special material called "hydrogel." Hydrogel has the property of changing its volume according to humidity, and this change is used to alter its color. While existing sensors had limited colors and slow response times, the research team enhanced the sensor's responsiveness by adding multiple layers of structure and tiny nano holes to the hydrogel.

In particular, this structure was designed to display various colors such as red (R), green (G), and blue (B), making the colors more vivid. Additionally, thanks to these nano holes, water molecules can directly contact the hydrogel, enabling faster response to humidity.

Made using light-based structures and precise processing technology, this sensor can detect humidity faster and express colors more accurately than conventional methods, and it is expected to be applicable to temperature and pressure measurement sensors as well.

The research team led by Professor Gil-Joo Lee of the Department of Electronic Engineering, School of Electrical and Electronic Engineering at Pusan National University, in collaboration with Professor Young-Min Song’s team from the Department of Electrical Engineering and Computer Science at Gwangju Institute of Science and Technology and Dr. Il-Seok Kang’s team at the Korea Institute of Nanotechnology, announced on the 15th that they successfully developed a high-reactivity, high-color-reproducibility structural color-based humidity sensor that changes color according to humidity.

(From left) Professor Gilju Lee, Professor Youngmin Song, Dr. Ilseok Kang, Master's student Heejun Nam, Dr. Joohwan Ko.

(From left) Professor Gilju Lee, Professor Youngmin Song, Dr. Ilseok Kang, Master's student Heejun Nam, Dr. Joohwan Ko.

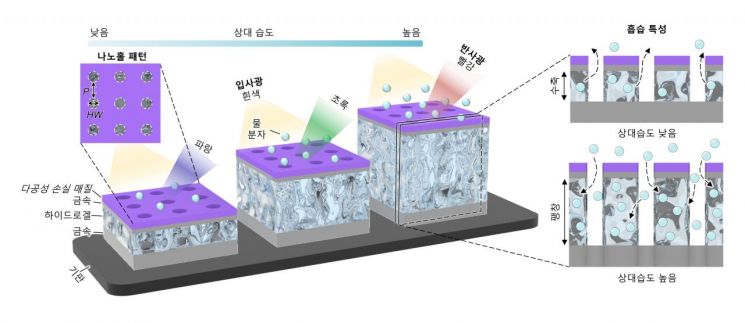

The fabric-parrot resonance structure-based metal-hydrogel-metal structure has been proposed as a humidity-responsive structural color that changes color according to the resonance thickness by utilizing the volume change characteristics of hydrogel. However, the existing structure was based on subtractive colors (CMY: cyan-magenta-yellow, colors darken as mixed), limiting the range of expressible colors, and the top metal layer hindered water molecules from penetrating the hydrogel layer, resulting in low responsiveness.

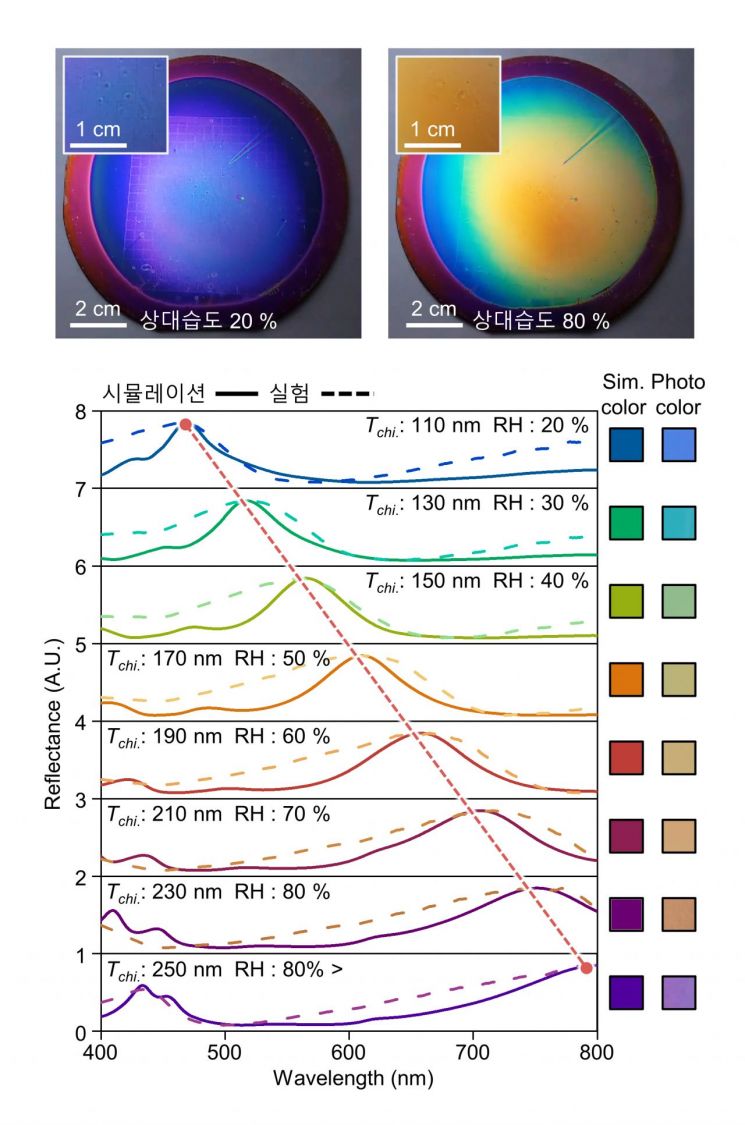

To address this, the research team added a lossy medium to the metal-hydrogel-metal structure to implement a multilayer Fano resonance structure, changing the reflected colors to additive colors (RGB: red-green-blue, colors brighten as mixed) to enhance the sensor’s color reproducibility. They also created nano-hole channels that allow water molecules to directly contact the hydrogel layer, improving responsiveness.

A lossy medium is a material that absorbs or scatters some light or energy passing through it, causing some of the light’s energy to appear lost rather than fully reflected or transmitted. The lossy medium interacts with light to create unique resonance phenomena, absorbing or dissipating energy in the process. When combined with multilayer structures, this enables the realization of structures with higher color reproducibility. For example, it can be used to effectively absorb or reflect light of specific wavelengths to change the color of the structure.

Fano resonance is a resonance phenomenon that occurs through the coupling of a continuous energy state structure (lossy medium) and a discrete energy state structure (metal-hydrogel-metal), with resonance results varying depending on the energy states of each structure and the degree of coupling. The research team designed a Fano resonance that produces highly color-reproducible reflected colors by using a porous lossy medium whose optical properties vary with porosity, and implemented the porous lossy medium using an oblique angle deposition method.

Meanwhile, adding a channel structure to the multilayer Fano resonance structure reduces the Fano resonance region, causing unwanted reflections that lower color reproducibility. To address this, the research team designed a nano-hole structure that induces the same plasmonic resonance regardless of polarization direction, maintaining Fano resonance while designing a reflected spectrum with higher color purity, thereby enhancing both color reproducibility and responsiveness.

The nano-hole pattern consists of hundreds of nanometers (nano, 10^-9) in size, making it difficult to realize practically with conventional lithography methods due to long processing times and high costs. However, the research team used the roll-to-plate nano imprint lithography process, which allows the pattern to be transferred over a large area quickly onto a pre-applied photosensitive layer as the roll rotates, similar to stamping.

The ultra-fast Fano resonance colorimetric humidity sensor, fabricated by integrating precise optical structure design and semiconductor process technology, demonstrated a high color expression of 141% within the standard RGB color space, a response time of 287 ms, and a recovery time of 87 ms.

Professor Gil-Joo Lee of Pusan National University said, “In this study, by combining multilayer Fano resonance structures with nano-hole structures, we were able to dramatically overcome the limitations of existing colorimetric humidity sensors.”

Professor Young-Min Song of Gwangju Institute of Science and Technology expressed expectations, saying, “This technology can be used not only for humidity measurement but also for developing colorimetric sensors for temperature and strain measurement using various materials.”

Dr. Il-Seok Kang of the Korea Institute of Nanotechnology added, “This research was possible thanks to the collaboration of the three research institutions, and I am especially pleased that the Korea Institute of Nanotechnology’s skilled nano-fabrication technology could greatly contribute to this groundbreaking development,” emphasizing that the research achievements are the result of cooperation.

This study involved Professor Gil-Joo Lee of Pusan National University, Professor Young-Min Song of Gwangju Institute of Science and Technology, and Dr. Il-Seok Kang of the Korea Institute of Nanotechnology as corresponding authors, with Hee-Jun Nam, a master’s student at Pusan National University, and Dr. Joo-Hwan Ko of Gwangju Institute of Science and Technology as first authors.

Supported by the Korea Research Foundation’s Basic Research Laboratory Advanced Program, Hanwoomulpagi Basic Research, Nano and Materials Technology Development Strategic Program, Sejong Science Fellowship, and Pusan National University BK21 FOUR Graduate Innovation Support Program, the results of this research are scheduled to be published in the October 20 issue of "Optica," a prestigious journal published by the Optical Society of America in the field of optics and photonics.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![From Hostess to Organ Seller to High Society... The Grotesque Scam of a "Human Counterfeit" Shaking the Korean Psyche [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)