Professor Seo Minho's Team Identifies Causes of Palladium Contamination Using Quantum Technology... Develops Recovery Technology

Semiconductor MEMS-Based Wireless Palladium Hydrogen Sensor Maintains Initial Performance for Over Two Months

While hydrogen gas is gaining attention as a clean energy source in various fields, there is now a way to safely detect it, even though it poses explosion risks at certain concentrations.

A research team at Pusan National University has developed a palladium-based hydrogen gas sensor that maintains excellent initial performance over long periods, raising expectations for innovation in the next-generation energy industry.

Pusan National University (President Choi Jaewon) announced on the 10th that a research team led by Professor Seo Minho of the School of Biomedical Convergence Engineering at the College of Information and Biomedical Engineering has succeeded in developing a high-sensitivity sensor technology that can wirelessly detect hydrogen gas concentrations stably over extended periods.

Hydrogen gas is attracting attention as an eco-friendly fuel with excellent energy efficiency, emitting only water when burned. However, colorless and odorless hydrogen becomes extremely explosive at concentrations above 4%, making safety management essential. In this context, where the development of ultra-sensitive hydrogen detection sensors is required, a domestic research team has developed a high-performance palladium-based sensor that maintains its performance over long periods.

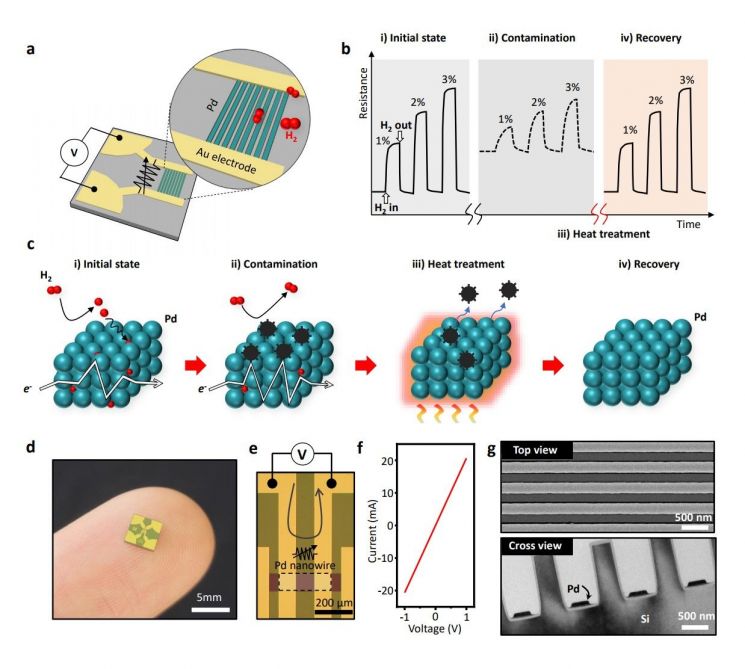

Existing hydrogen detection sensors using palladium (Pd), a silvery-white metal, are highly sensitive but have the limitation of rapid performance degradation due to contamination when exposed to the atmosphere. This research identified the fundamental cause of palladium surface contamination and proposed a method to completely eliminate it.

The research team revealed, through density functional theory (DFT) based on quantum mechanics and experimental analysis, that carbon dioxide (CO₂) in the atmosphere is the main culprit contaminating the palladium surface. They developed a technology to perfectly restore the initial performance of palladium by removing contaminants with heat at 200°C.

Based on this technology, the team applied semiconductor-based microelectromechanical systems (MEMS) to fabricate a high-performance palladium hydrogen sensor the size of a fingernail. They succeeded in completely restoring its initial performance with heat treatment, even after leaving it exposed to the atmosphere for more than two months.

Professor Seo Minho, who led the research, stated, "This achievement provides a groundbreaking turning point for preventing hydrogen gas leakage accidents and enhancing the safety of hydrogen energy, and it will become a core technology in the hydrogen economy."

The results of this research were published online on October 9 in the international journal 'Nature Communications' under the title 'Long-term reliable wireless H2 gas sensor via repeatable thermal refreshing of palladium nanowire.'

This research was jointly conducted by Professor Seo Minho's team at the School of Biomedical Convergence Engineering at Pusan National University, Professor Kang Junhee's team at the Department of Nanoenergy Engineering, and Professor Yoon Junbo's team at the Korea Advanced Institute of Science and Technology (KAIST), with support from the 2024 Leading Research Center Program, the Mid-career Researcher Program, and the Innovation Research Center Program of the Ministry of Science and ICT and the National Research Foundation of Korea.

Research on Semiconductor-type MEMS-based Wireless Palladium Hydrogen Sensor by Professor Minho Seo of Pusan National University.

Research on Semiconductor-type MEMS-based Wireless Palladium Hydrogen Sensor by Professor Minho Seo of Pusan National University.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.