UNIST and LG Chem Develop Catalyst for Producing Aviation Fuel with 80% Carbon Emission Reduction

Isoparaffin-Generating Catalyst Increases Commercialization Potential of Sustainable Aviation Fuel

A catalyst technology for producing sustainable aviation fuel (SAF) that can significantly reduce carbon emissions by utilizing carbon dioxide has been developed.

By capturing carbon dioxide from the atmosphere and generating high-value-added hydrocarbon isoparaffin, this technology is expected to contribute to carbon neutrality.

The research team led by Professor Kwangjin Ahn of the Department of Energy and Chemical Engineering at UNIST (President Jongrae Park) and the Carbon Neutrality Research TFT of LG Chem has developed a catalyst for isoparaffin production suitable for SAF production using carbon dioxide. Used in conjunction with an iron-based catalyst, it replaces conventional zeolite catalysts and has successfully achieved a significant increase in the isoparaffin yield.

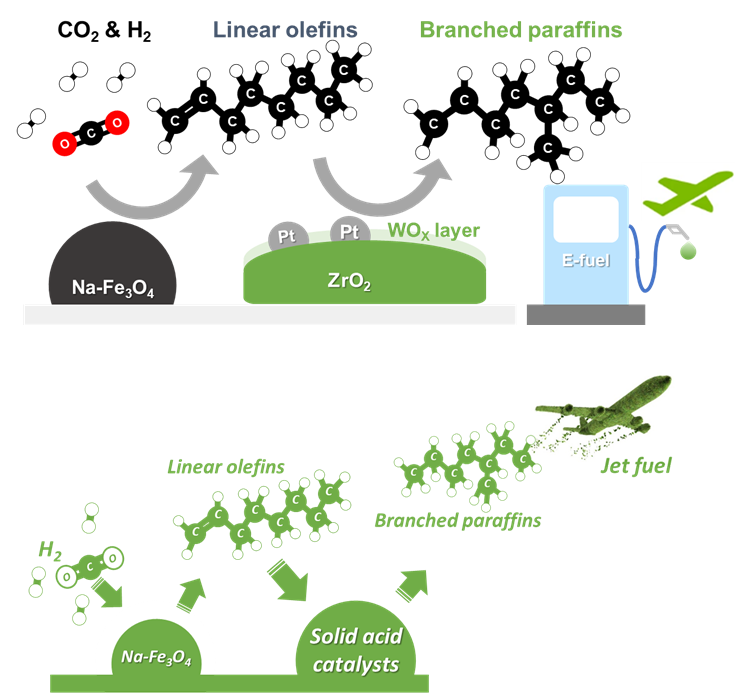

Composition of isoparaffin production via direct hydrogenation of carbon dioxide using iron catalyst and acid catalyst-based reactions.

Composition of isoparaffin production via direct hydrogenation of carbon dioxide using iron catalyst and acid catalyst-based reactions.

In particular, aviation fuel produced using a platinum-based tungsten-zirconia catalyst is expected to reduce carbon emissions by up to 80% compared to conventional fossil fuel-based aviation fuel. By directly converting carbon dioxide into isoparaffin, the process efficiency has also been greatly improved.

This catalyst exhibits low carbon deposition and enables stable reactions over long periods, making it highly promising for commercialization. It is expected to help drastically reduce carbon emissions not only in the aviation industry but also in other transportation sectors.

Professor Kwangjin Ahn explained, "We have overcome the limitations of conventional zeolite catalysts, which are vulnerable to coking during reactions, and presented a new catalytic method that maximizes the isoparaffin yield."

Professor Kwangjin Ahn.

Professor Kwangjin Ahn.

Wonhee Kim, principal researcher at LG Chem, emphasized, "This technology enhances the economic efficiency of fuel and minimizes costs incurred during additional refining processes, making it highly valuable for industrial applications."

Wonhee Kim, Senior Researcher at LG Chem.

Wonhee Kim, Senior Researcher at LG Chem.

Currently, the aviation transport sector accounts for 24.5% of total carbon dioxide emissions, and the commercialization of SAF has emerged as an urgent task to achieve carbon neutrality. The International Air Transport Association is strengthening regulations to increase the use of SAF.

The research was conducted with technical support from the Korea Basic Science Institute, and the results were published online in the world-renowned international journal 'ACS Catalysis' on August 9. The research was supported by the National Research Foundation of Korea and the Materials, Parts, and Equipment Support Program of the Ministry of Trade, Industry and Energy.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.