9th Generation TLC Mass Production Followed by QLC in 4 Months

Read/Write Power Consumption Improved by 30% and 50%

Samsung Electronics has become the first in the industry to mass-produce enterprise solid-state drive (eSSD) quad-level cell (QLC) NAND flash products, which are experiencing rapidly increasing demand in the artificial intelligence (AI) server sector. This expands its portfolio of AI SSD products.

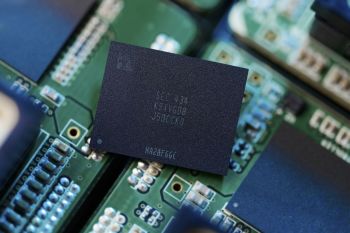

Samsung Electronics' 9th generation QLC V-NAND product, the industry's first mass-produced model.

Samsung Electronics' 9th generation QLC V-NAND product, the industry's first mass-produced model. [Photo by Samsung Electronics]

On the 12th, Samsung Electronics announced that it has become the first in the industry to mass-produce 1Tb (terabit) capacity QLC 9th generation (286-layer) NAND. Following the industry's first mass production of 'triple-level cell (TLC) 9th generation NAND' in April, Samsung has now introduced QLC products for the first time. QLC can record 4 bits of data per cell, offering higher performance than TLC, which records only 3 bits.

Samsung's 9th generation V-NAND achieved the industry's highest number of layers at 286 through channel hole etching technology and a double stack structure. In particular, the 9th generation QLC product minimized the area of the cell and peripheral circuits (peri). It increased the number of stored bits per unit area by about 86% compared to the previous generation, meaning a significant increase in capacity.

As the stacking number of V-NAND layers increases, maintaining uniform cell characteristics between and within layers becomes increasingly important. To address this, Samsung Electronics applied 'Designed Mold' technology to the product. Designed Mold is a stacking technology that adjusts the spacing of wordlines (WL) that operate the cells. By applying this technology, the product's data retention performance improved by about 20% compared to previous products.

By applying 'predictive program technology,' write performance improved by 100% and data input/output speed by 60% compared to the previous generation QLC. This technology predicts changes in cell status to minimize unnecessary operations.

Additionally, through low-power design technology, power consumption for data reading and writing was reduced by approximately 30% and 50%, respectively. Power consumption was lowered by reducing the voltage driving the NAND cells and sensing only the necessary bit lines (BL). BL refers to the wiring responsible for data writing and reading.

Huh Sung-hoe, Vice President of the Flash Development Office at Samsung Electronics' Memory Business Division, said, "We succeeded in mass-producing QLC NAND just four months after producing 9th generation TLC NAND, completing the latest lineup required by the AI high-performance and high-capacity SSD market. Samsung Electronics' leadership in the rapidly growing eSSD market for AI will be further highlighted."

Samsung Electronics plans to expand applications of 9th generation QLC V-NAND based products, starting with branded products and extending to mobile universal flash storage (UFS), PC, and server SSDs in the future.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.