UNIST Research Team Achieves Precise Gas Detection by Combining Nanotechnology and Deep Learning

Ultra-Low Power Operation Below 200 Microwatts... Enhanced Efficiency and Cost-Effectiveness

An ultra-miniature electronic nose that operates with ultra-low power consumption has been developed.

This innovation opens up possibilities for application in various fields such as air quality monitoring, health diagnostics, food safety, and environmental protection.

A research team led by Professor Shin Heungjoo from the Department of Mechanical Engineering and Professor Kim Jaejun from the Department of Electrical and Electronic Engineering at UNIST (President Park Jongrae) has successfully implemented an electronic nose capable of precisely measuring the type and concentration of gases by combining nanofabrication and deep learning technologies.

From the left, Professor Kim Jaejun, Researcher Kim Yonggi, Researcher Kim Taejung, Professor Shin Heungjoo.

From the left, Professor Kim Jaejun, Researcher Kim Yonggi, Researcher Kim Taejung, Professor Shin Heungjoo.

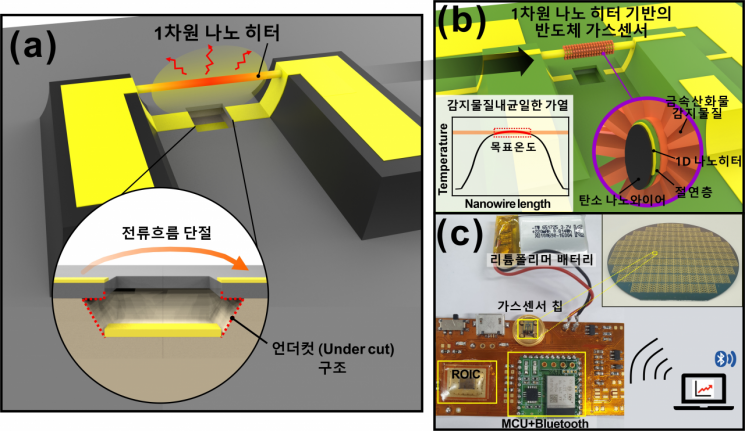

The newly developed electronic nose uses a semiconductor gas sensor based on a nano-sized heater. While conventional sensors consume a lot of power due to their high operating temperatures, this sensor can operate with less than 200 microwatts of power. It is suitable for mobile and IoT devices, and its productivity is enhanced by manufacturing the sensor using semiconductor processes.

By miniaturizing the sensor, the team reduced the high power consumption typical of conventional electronic noses. They further decreased power consumption by up to 90% by introducing duty cycling technology, which periodically supplies and cuts off power to minimize energy usage.

The nano-sized heater can be rapidly heated to 250 degrees Celsius and cooled to room temperature in just one ten-thousandth of a second, enabling smooth gas measurement even during short duty cycles.

The research team improved the conventional electronic nose structure, which previously required multiple sensors, so that it can now operate with a single sensor. The desorption of gases adsorbed on the semiconductor surface is slower than the operation speed of the nanoheater. As a result, even during the brief cooling periods in rapidly repeating duty cycles, gas reactions continue. This allows for the collection of different signals during heater operation and shutdown. By analyzing these dual signals in real time using a convolutional neural network (CNN), the system can accurately identify the type and concentration of various gases.

One-dimensional nano heater-based semiconductor gas sensor and real-time wireless monitoring system based on it.

One-dimensional nano heater-based semiconductor gas sensor and real-time wireless monitoring system based on it.

Professor Shin Heungjoo stated, "We have overcome the limitations of conventional electronic noses with a single sensor, making it easy to apply to mobile and IoT devices where miniaturization is essential."

Professor Kim Jaejun explained, "By implementing an ultra-miniature gas measurement device that operates with low power, it can be utilized in various application fields such as real-time wireless monitoring systems."

The research results were published in the nanotechnology journal Small and the international journal ACS Sensors. The nanoheater-based gas sensor was featured in September 2022, and the electronic nose technology was announced in June 2024, with both selected as cover papers.

The research was supported by the National Research Foundation of Korea (NRF) under the Ministry of Science and ICT, the Ministry of Trade, Industry and Energy, and the Ministry of Science and ICT.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)