Simultaneous Measurement of Water Pipe Corrosion and Water Quality Published in Nature Partner Journal 'npj Clean Water'

The research team led by Professor Lim Haegyun and student Sung Youngho from the Department of Biomedical Engineering at Pukyong National University, in collaboration with Professor Lee Ojun from The Catholic University of Korea and Dr. Hwan Ryul Jo from Flowserve Corporation in the United States, has developed a system capable of simultaneously measuring both the corrosion of water supply pipes and the water quality inside the pipes through a global joint research project.

Professor Im Haekyun of Pukyong National University, undergraduate student Sung Youngho, Professor Lee Ojun of Catholic University, Hwan Ryul Jo of Flowserve Corporation, USA.

Professor Im Haekyun of Pukyong National University, undergraduate student Sung Youngho, Professor Lee Ojun of Catholic University, Hwan Ryul Jo of Flowserve Corporation, USA.

The results of this research were published in the paper titled "Internal pipe corrosion assessment method in water distribution system using ultrasound and convolutional neural networks" in a Nature partner journal (IF: 10.4, JCR 1.6% in Water Resources).

Iron oxide deposits caused by pipe corrosion can contaminate water, leading to serious health issues such as gastrointestinal infections, skin problems, and lymph node complications. Additionally, corrosion weakens pipe walls, increasing the risk of leaks or ruptures, which can result in higher repair costs and interruptions in water supply.

Accordingly, there has been a demand for a non-destructive and continuous corrosion monitoring assessment method that can protect water quality and extend pipe lifespan by enabling early detection of pipe conditions and proper maintenance. Conventional corrosion assessment methods often require damaging the pipes or shutting down the system, resulting in economic inefficiency.

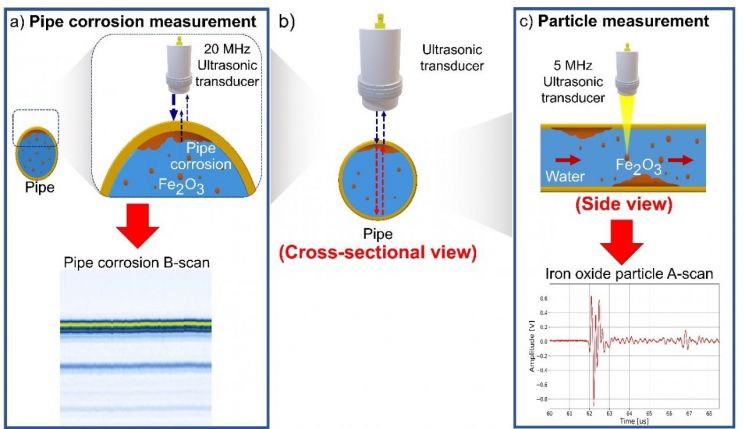

The research team developed a dual-diagnosis system that enables non-destructive and continuous monitoring using ultrasound and artificial intelligence. By utilizing a high-frequency scanning acoustic microscope (SAM), they successfully generated high-resolution pipe thickness images to monitor the degree of pipe corrosion. At the same time, they used a convolutional neural network (CNN) to analyze ultrasonic signals inside the pipes to measure the concentration of iron oxide in the water.

As a result, measurements of pipes with a thickness reduction of 69 to 80 micrometers due to corrosion using the high-frequency microscope showed an error margin within 5%. Additionally, the classification of iron oxide concentration inside the pipes using the CNN achieved an accuracy of up to 99%. The implementation of such a dual-diagnosis system capable of both pipe corrosion and water quality analysis in industrial settings is expected to enable efficient and precise management of pipe infrastructure.

Professor Lim Haegyun's research team conducted this study with support from BK21 Four, the National Research Foundation of Korea's Excellent Young Researcher Program, the Regional Leading Research Center (RLRC), and the BrainLink Excellent Researcher Exchange Program, publishing the paper on July 13.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)