Evaluation of Waste Plastic Upcycling Process Secures Green Growth Potential

Development of Carbon Nanotube Production System... Utilization of Renewable Energy Sources

A technology that converts waste plastic into high-value-added material, carbon nanotubes (CNT), has been developed by a research team at UNIST.

Plastic waste is expected to be transformed into a key resource for carbon neutrality and the circular economy.

Professor Kwangjin Ahn, UNIST.

Professor Kwangjin Ahn, UNIST.

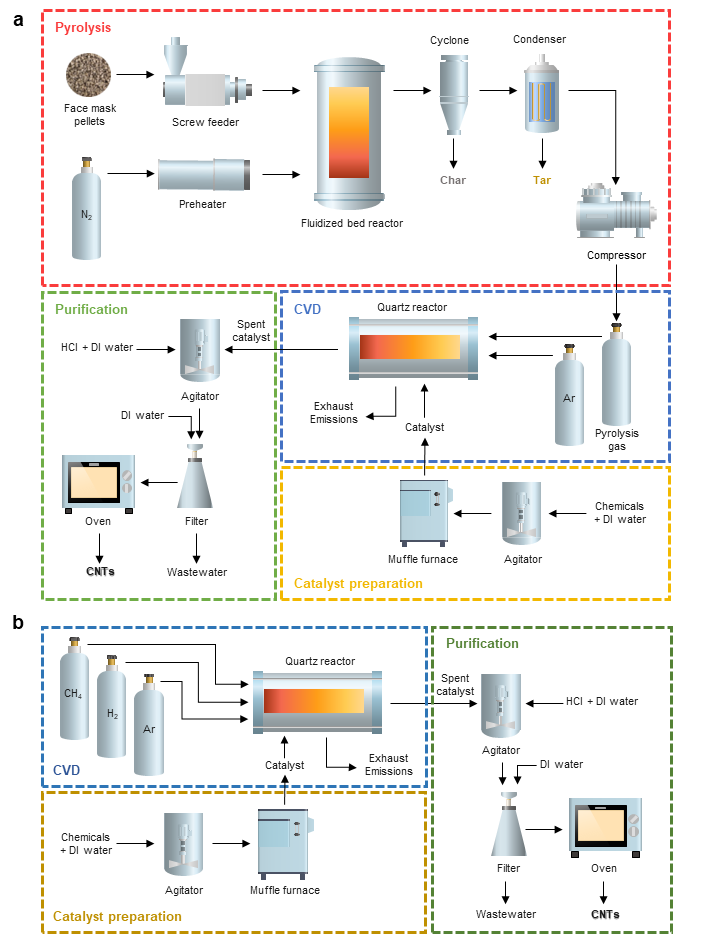

The joint research team led by Professors Kwangjin An and Hangwon Lim from the Department of Energy and Chemical Engineering at UNIST (President Park Jongrae) has devised a method to produce carbon nanotubes using mixed gases generated from discarded masks. When waste plastic undergoes pyrolysis, it is converted into hydrocarbon gases such as methane, ethylene, and propylene. These gases are then processed at high temperatures to be transformed into carbon nanotubes.

The carbon nanotubes produced through this upcycling process are environmentally friendly. Compared to conventional methane and hydrogen-based processes, this method emits less carbon dioxide. It also has the advantage of processing gases without the need for waste separation.

Utilizing gases generated from the pyrolysis of mask waste enables the mass production of carbon nanotubes at a low cost. Notably, despite the complexity of the upcycling system, it can be operated at a cost similar to existing methods.

The research team presented a carbon-neutral strategy through scenario analysis using renewable energy. They conducted the first economic and environmental assessment of carbon nanotube production via waste plastic upcycling, confirming new possibilities for converting plastic waste into high-value-added materials.

First authors Kim Heehyang and Nam Eonwoo stated, "If the scale of this process is expanded and power supply using renewable energy is secured, production can be achieved at a low cost. Carbon dioxide emissions can also be dramatically reduced."

Professors Hangwon Lim and Kwangjin An commented, "As pyrolysis technology advances and the supply of carbon nanotubes increases, it will also contribute to energy security. In the future, we plan to design larger-scale devices beyond the laboratory level to secure technology applicable to actual industry."

This research was supported by the UNIST Carbon Neutral Demonstration Center, the Defense Acquisition Program Administration, the Ministry of Trade, Industry and Energy, the National Research Foundation of Korea under the Ministry of Science and ICT, and JO Technology. The results were published online in the international journal Chemical Engineering Journal on June 28.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)