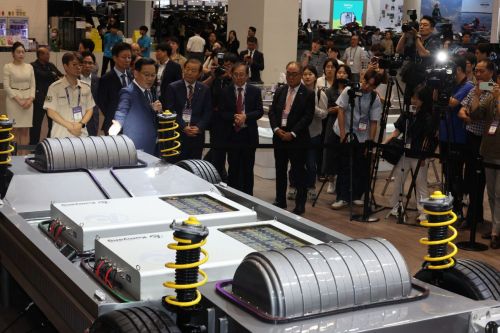

Kwangyong Lee, Vice President of Geumyang, is unveiling a model of a four-wheel-drive complete vehicle equipped with a 4695 cylindrical battery at the Busan Mobility Show press day held at BEXCO in Haeundae-gu, Busan on June 27. 2024.6.27

Kwangyong Lee, Vice President of Geumyang, is unveiling a model of a four-wheel-drive complete vehicle equipped with a 4695 cylindrical battery at the Busan Mobility Show press day held at BEXCO in Haeundae-gu, Busan on June 27. 2024.6.27 [Photo by Yonhap News]

Geumyang announced that it will complete the construction of its Gijang factory by the end of this year and start mass production of 2170 cylindrical batteries from March next year. The goal is to begin the first mass production of 4695 batteries in June next year.

Kim Chan-jung, a research fellow at Geumyang, announced this roadmap on the 23rd at the 2024 SNE Battery Day held at the Science and Technology Center in Yeoksam-dong, Seoul.

Geumyang is building a cylindrical battery factory in Gijang, Busan, on a site area of 180,296㎡ with a total floor area of 63,759㎡. Currently, the building is 70% complete, and equipment capable of producing actual batteries is planned to be installed starting in September.

The Gijang factory will be constructed in two phases. Currently, the first phase factory, capable of producing 200 million cells of 2170 cylindrical batteries (3.7GWh) and 100 million cells of 4695 cylindrical batteries (12.5GWh), is under construction. When fully completed, the total capacity will be 16.2GWh, which, based on 75 kilowatt-hours (kWh), can be installed in 216,000 electric vehicles.

Geumyang plans to sequentially start operating the 2170 cylindrical battery production line, capable of producing 100 million cells, by the end of this year. The first mass production of 4695 batteries is targeted to begin in June next year.

Currently, Geumyang is producing 7 million cells annually of 2170 cylindrical batteries on a pilot line. The gravimetric energy density of the 2170 cylindrical battery is 272Wh/kg.

Geumyang is also developing the 4695 cylindrical battery with an energy density of 290.2Wh/kg. This surpasses Tesla's 4680 cylindrical battery energy density of 243.4Wh/kg. Geumyang explained that the capacity of the 4695 battery is 34.0 ampere-hours (Ah), which is superior to Tesla's 23.4Ah.

Research fellow Kim Chan-jung explained, "The cathode uses high-nickel NCMA with 97% nickel content developed by our subsidiary SM Lab, and the anode applies graphite with less than 5% silicon."

As a result, when installing a 75kWh capacity in an electric vehicle, Geumyang's 4695 battery requires 600 cells, while Tesla requires 867 cells, reducing the number of cells per vehicle by 31%. Also, with 600 cells installed, Geumyang's battery can drive 600 km (based on 8 km per kWh), which is 44% longer than Tesla's 416 km, according to Geumyang. The 4695 battery is currently undergoing tests for commercial production at the secondary battery R&D center, with plans to start mass production in June 2025.

Geumyang is conducting sample evaluations with customers for the 2170 cylindrical battery. Research fellow Kim said, "We have received positive evaluations from several companies regarding the 2170 battery." A Geumyang official explained, "We are currently conducting sample evaluations for customers regarding both the 2170 and 4695 batteries, and the sales progress varies from 30% to 95% depending on the customer."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.