Hyundai Transys has applied the AI technology-based system 'TADA (Transys Advanced Data Analytics)' to its production sites, increasing defect inspection accuracy to 99.9%.

The TADA system is a digital platform developed by Hyundai Transys by applying AI technology to drive business innovation. It is used across all operations, including implementing smart manufacturing technology, data-driven big data platforms, and digital transformation capability enhancement training for employees. In particular, the in-house developed programs using AI deep learning technology, ▲TADA Smart Solution ▲TADA Edge Solution, contribute to quality enhancement by improving defect inspection accuracy in manufacturing sites.

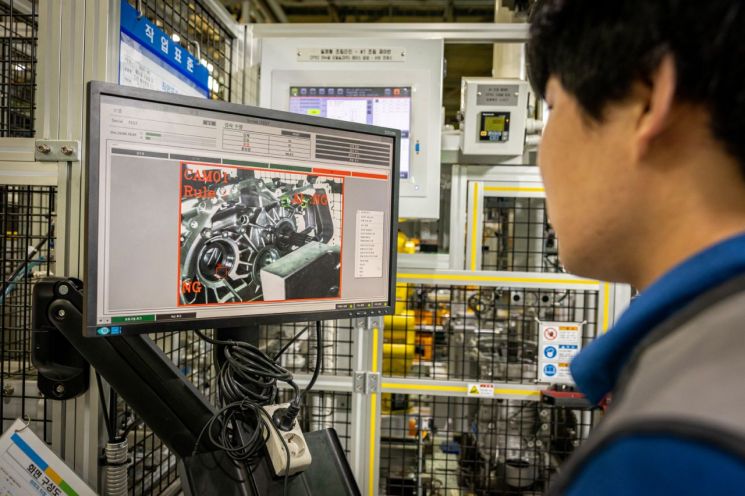

The 'TADA Smart Solution' applied at Hyundai Transys Seosan Plant conducting parts quality inspection using AI technology

The 'TADA Smart Solution' applied at Hyundai Transys Seosan Plant conducting parts quality inspection using AI technology[Photo by Hyundai Transys]

The TADA Smart Solution detects defects during the scanning process that checks for small bubbles or damages inside parts in the manufacturing and assembly process using deep learning AI as a vision inspection solution. It captures defects that humans might miss, raising inspection accuracy from the previous 93% to 99.9%. It has been applied to seven processes at Hyundai Transys Seosan Plant and 54 processes at the Georgia Powertrain Plant in the United States.

The TADA Edge Solution is a compact AI inspection solution developed to allow non-experts to easily create customized deep learning models and apply them on-site. By collecting production process images such as the mounting status and quantity confirmation of parts to be inspected through a small camera and performing labeling work, the TADA Edge Solution learns and then conducts defect inspections. Currently, it is used in four locations at the Seosan Plant for inspecting the number of assembled bolts, mounting status, and joint looseness. This solution is also provided to partner companies to help build smart factories.

Hyundai Transys has improved work efficiency by utilizing TADA AI not only in production sites but also in research and development. The Electrification R&D Headquarters applied AI technology to durability testing during the powertrain gear development process. The gear durability inspection, which took up to 24 hours when done manually, was reduced to about one hour by introducing deep learning AI measurement machines.

Kim Young-wook, Executive Director of Hyundai Transys ICT Promotion Office, said, "Since 2022, through TADA in-house training, employees have been leading a change in work methods based on data," adding, "We will strive for digital innovation and improved work efficiency across all business areas of Hyundai Transys, including production, development, and support."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.