Launch of High-Voltage MLCC Lineup for 800V Electric Vehicle BMS

Enabling Reduced Charging Time and Vehicle Weight Reduction

Samsung Electro-Mechanics announced on the 17th that it has developed a 2000V (volt) multilayer ceramic capacitor (MLCC) for electric vehicle battery management systems (BMS).

The battery management system of an electric vehicle manages the battery's current, voltage, temperature, and other factors, serving a role similar to the engine in internal combustion engine vehicles. Since the driving range of electric vehicles is determined by battery capacity, there is a trend toward increasing capacity. To rapidly charge high-capacity batteries, the operating voltage is expected to continue rising.

Currently, electric vehicles mainly use 400V battery management systems, but recently, 800V high-voltage battery systems have been applied primarily in plug-in hybrid electric vehicles (PHEV) and battery electric vehicles (BEV). The 800V high-voltage battery system offers advantages over the existing 400V system, such as reduced charging time, vehicle weight reduction, and design space optimization. Accordingly, the proportion and demand for 2000V high-voltage, high-reliability MLCCs with more than twice the safety margin that can operate stably in 800V high-voltage electric vehicles are expected to increase.

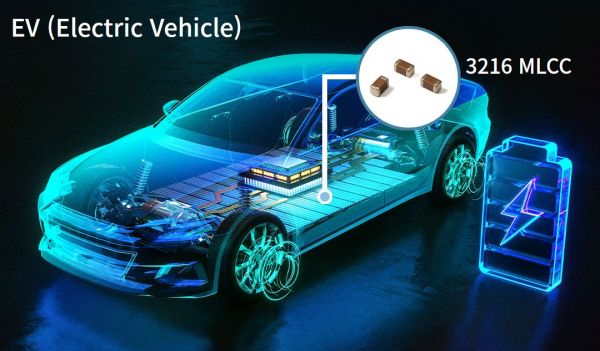

High-voltage MLCC for electric vehicle battery management systems by Samsung Electro-Mechanics.

High-voltage MLCC for electric vehicle battery management systems by Samsung Electro-Mechanics. [Photo by Samsung Electro-Mechanics]

High-voltage MLCCs for electric vehicles face challenges in securing reliability due to internal cracks and electrical discharges caused by high voltage, as their operating voltage environment is more than 300 times higher than the 6.3V used in general IT MLCCs. High-voltage MLCCs are high-difficulty, high-value-added products because they guarantee durability in harsh environments and supply current.

To address these issues, Samsung Electro-Mechanics applied a voltage distribution safety design that can stably distribute high voltage inside the MLCC. Additionally, based on its proprietary raw material development technology, Samsung Electro-Mechanics secured MLCC product reliability through dielectric particle size reduction.

Samsung Electro-Mechanics developed two types of products to operate stably in high-voltage environments: 3216 size (3.2mm X 1.6mm) MLCCs rated for 2000V with capacitances of 1nF (nanofarad) and 2.2nF. Samsung Electro-Mechanics independently developed raw materials and changed the internal electrode structure to develop MLCCs that operate stably even at high voltages, and obtained AEC-Q200 certification, the automotive electronic component reliability test standard.

Choi Jae-yeol, Vice President and Head of the Component Business Division at Samsung Electro-Mechanics, said, "Through the development of 2000V high-voltage products, we have proven Samsung Electro-Mechanics' MLCC technology for automotive applications," adding, "Samsung Electro-Mechanics will expand its market share in automotive MLCCs through timely development aligned with electric vehicle trends and market demand."

Meanwhile, the high-voltage MLCC market is expected to steadily grow due to the expansion of the electric vehicle market and the high-voltage trend in battery systems for fast charging and increased driving range. The high-voltage MLCC market size is projected to grow at an average annual rate of about 22%, from $4 billion in 2024 to approximately $11 billion by 2029.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.