Supply of 23,000 Reverse Osmosis Membranes for Gubra Project

Desalination of 770,000 Tons per Day... Nearly Half of Total Desalination Volume

LG Chem will supply reverse osmosis membranes (RO membranes) to the largest desalination plant in Oman. It is expected that half of the water desalinated in Oman will be produced through LG Chem's reverse osmosis membranes.

On the 15th, LG Chem announced that it will supply 23,000 reverse osmosis membranes to GS Inima, the engineering, procurement, and construction (EPC) company for the Ghubrah Phase 3 desalination project in Oman. This scale can desalinate 100 million tons of seawater annually (300,000 tons per day), producing water used by 2.5 million people in the metropolitan area of Oman.

The Ghubrah Phase 3 desalination project is a reverse osmosis seawater desalination plant located in the coastal area of Muscat, the capital city. Once it begins operation in the first quarter of 2027, it will become the largest desalination facility in Oman.

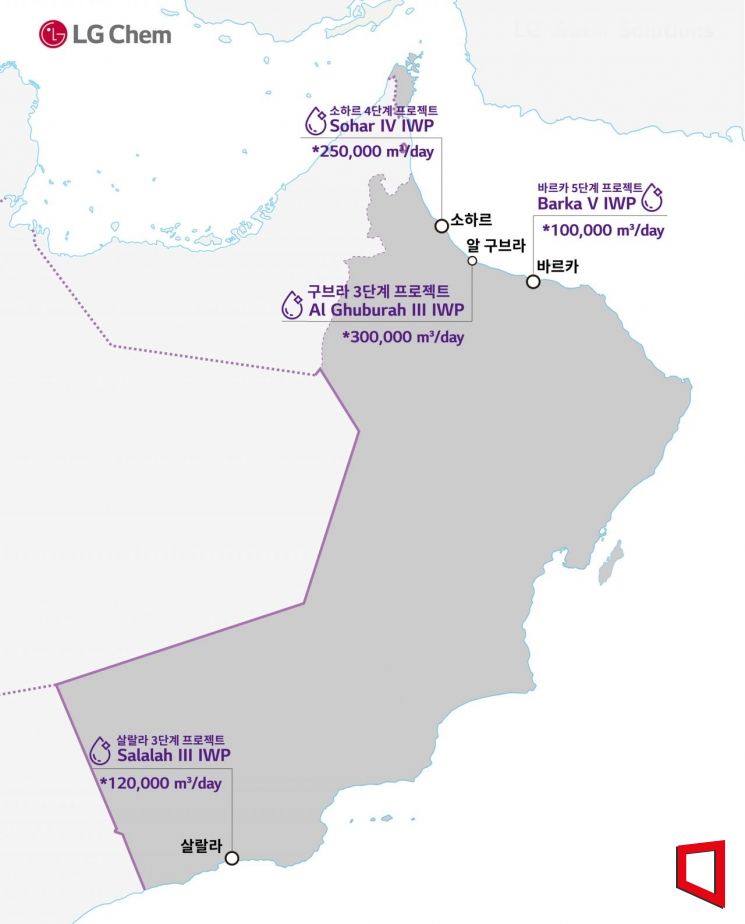

LG Chem's reverse osmosis membranes have been desalinating 470,000 tons of water per day in the Oman region. With the addition of the Ghubrah Phase 3 project, the daily desalination volume will reach 770,000 tons. The total seawater desalination capacity in Oman is 1.5 million tons per day. Oman, located in a desert climate with low rainfall, focuses on securing water resources through desalination. In particular, it is continuously promoting large-scale desalination projects through its mid- to long-term national plan, 'Vision 2040.'

LG Chem entered the Oman market in 2016 by supplying reverse osmosis membranes to the Sohar desalination plant with a daily desalination capacity of 250,000 tons. It also applied reverse osmosis membranes to the Salalah project, producing 120,000 tons of drinking water per day in 2018, and to the Barka Phase 5 desalination plant with a daily capacity of 100,000 tons in 2021.

LG Chem's reverse osmosis membrane (RO) to be introduced at Ashdod seawater desalination plant in Israel (Provided by LG Chem)

LG Chem's reverse osmosis membrane (RO) to be introduced at Ashdod seawater desalination plant in Israel (Provided by LG Chem)

LG Chem's reverse osmosis membranes achieve a world-class salt removal rate of 99.89%. They require less pressure for desalination, enabling energy savings, and by applying Thin Film Nanocomposite (TFN) technology that coats nanoparticles on the membrane surface, they maintain salt removal efficiency while providing over 20% higher flow rate compared to competitors' products.

Hyung Hoon, Executive Director of LG Chem's RO Membrane Business Division, said, "Since we have established our presence in Oman from the early stages of the business, we consider it meaningful to participate in the Ghubrah Phase 3 project, which will become a major water supplier in Oman. We will work together with our clients to provide clean and sustainable water supply."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.