Addressing Both Worker Safety Accidents and Human Errors at the Same Time

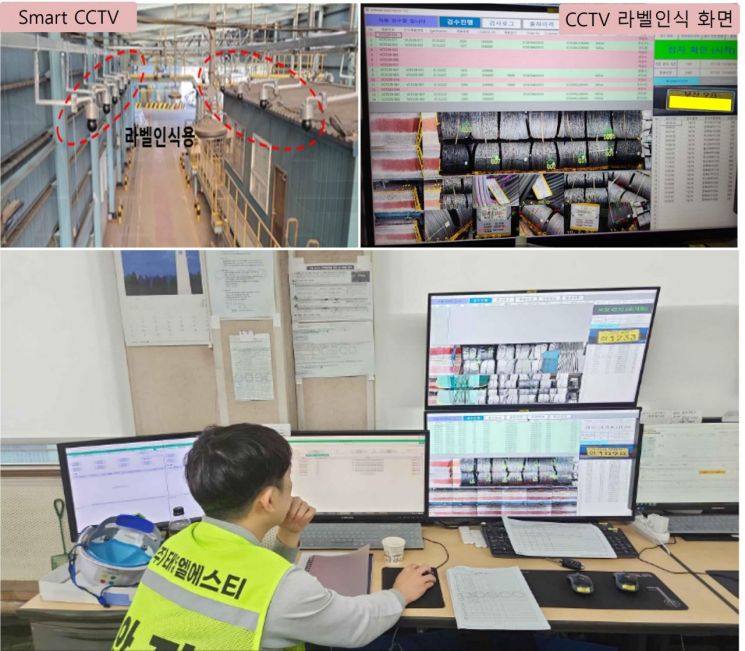

POSCO Pohang Steelworks has automated the inspection process for wire rod products by integrating Smart CCTV product label detection with AI-based character recognition technology.

POSCO Pohang Steelworks has developed technology to automate the inspection process of wire rod products and is monitoring the automated inspections.

POSCO Pohang Steelworks has developed technology to automate the inspection process of wire rod products and is monitoring the automated inspections.

At the inspection site, where production information for products such as wire rods, coils, and plates produced at Pohang Steelworks is checked against the actual items loaded onto vehicles for shipment to customers, there are cases where the product label is attached on the opposite side of the inspection position. In such cases, inspectors must board the vehicle and visually inspect the labels themselves.

During this process, the possibility of human error increases as inspectors visually compare MES invoice information with product labels, which can lead to customer claims. Furthermore, focusing on inspection tasks while standing atop loaded vehicles can result in unexpected safety accidents.

To address these issues, the Product Shipment Section of the Production Technology Department collaborated with POSCO DX to develop the 'Wire Rod Product Label Inspection Automation' technology using 12 Smart CCTV cameras.

This technology features a 'tracking coordinate video analysis' model that controls the rotation and zoom functions of the 12 cameras, automatically tracking the label positions of irregularly loaded wire rod products on vehicles, recognizing the characters, and comparing the recognized text with MES data. The inspection results are then output to the system, achieving full automation of the inspection process without human intervention.

The key feature of this smart technology is the use of an object recognition AI algorithm that not only views fixed screens but also allows the AI model to directly control the angle and zoom functions of the CCTV to locate label positions.

Applying the developed object recognition AI algorithm to existing CCTV systems enables easy expansion of this automation to inspection sites for other products such as plates and coils, in addition to wire rod products.

A representative from Pohang Steelworks stated that, through this automation, there are plans to expand the application of this technology to coil and plate product inspection sites by 2025.

Kim Sungwook, the manager in charge of this technology development at the Product Shipment Section, said, "I am very proud to have developed a Smart + AI convergence technology that can prevent both safety accidents and human error at the product shipment site," and added, "I hope to continue discovering various Smart projects in the field to contribute to the company's development."

Pohang Steelworks is accelerating efforts to enhance productivity and profitability by utilizing CCTV as the eyes of operators, integrating AI technology for automating visual tasks, real-time monitoring of operational status and material quality, and reducing operator workload.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.