POSCO E&C is strengthening its competitiveness by advancing intelligence in the construction industry based on innovative artificial intelligence (AI) technology.

POSCO E&C established a dedicated smart construction organization in 2018 and has been focusing on developing smart technologies. This year, it is actively incorporating AI, construction robots, and other technologies into Building Information Modeling (BIM) to increase productivity on construction sites and reduce risks, thereby advancing its smart technology strategy.

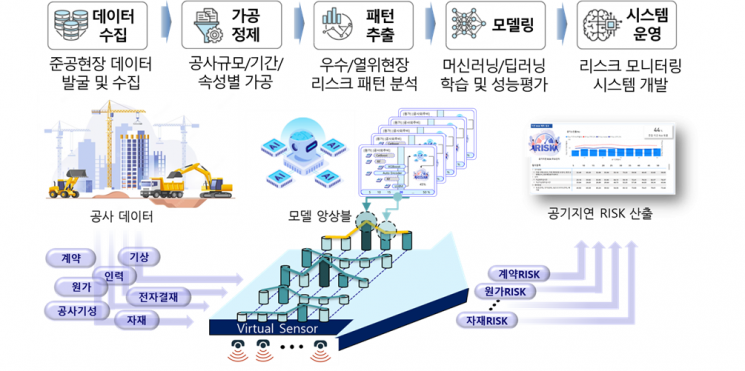

The foundation of AI technology development is the big data from projects conducted so far. Using deep learning, construction-specialized AI models are applied to core tasks in the project life cycle (PLC). Through this, POSCO E&C is enhancing work efficiency and minimizing errors, progressing toward intelligent project management.

One representative AI technology is the regional real estate market analysis system. It digitizes data on supply and demand, prices, transactions, development prospects, economy, and market indicators over 10 years for 219 cities, counties, and districts nationwide, and analyzes the market status quickly based on AI models. This model can identify key influencing factors affecting the real estate market in the respective regions. A POSCO E&C official stated, "We can check market analysis values in real time, actively discovering cities that need housing supply and determining the appropriate supply scale and timing."

There is also a system that predicts prices of market-sensitive materials such as rebar, ready-mixed concrete, steel plates, and PHC piles. Using a time-series data-based prediction model, it allows users to check price trends. It shows future prices up to six months ahead in maximum, average, and minimum price ranges, and classifies risk indices into four levels to support purchasing plans at each project stage. This helps establish optimal purchasing strategies such as early ordering to minimize the burden of rising construction costs. Accuracy is improved by reflecting causal factors like raw material prices and interest rates.

The rebar consumption prediction model is used in new apartment construction. POSCO E&C calculates rebar usage by type of apartment through machine learning-based big data analysis of past apartment projects it has constructed. Since accurate prediction of rebar usage is possible from the estimation stage, stable rebar supply and construction quality assurance are achievable. It reduces estimation time by more than 60% compared to before and improves accuracy up to 95%.

Additionally, accumulated data on apartment project performance shows the risk of schedule delays by key factors such as construction, procurement personnel, and costs. Project execution risk measured monthly can be intuitively checked through a dashboard, enabling early detection of abnormal signs and proactive responses in the early construction phase. The official explained, "We are actively using this in ongoing apartment sites to minimize issues such as delays in move-in caused by schedule extensions."

Conceptual Diagram of Early Detection Monitoring System for Air Delay Risk in Multi-family Housing / Image provided by POSCO E&C

Conceptual Diagram of Early Detection Monitoring System for Air Delay Risk in Multi-family Housing / Image provided by POSCO E&C

The intelligent closed-circuit television (CCTV) safety facility installation monitoring system is also noteworthy. It analyzes video information obtained from existing CCTV using AI technology to monitor in real time whether safety facilities such as fall-prevention covers and safety railings have been arbitrarily dismantled, and sends alerts to prompt restoration actions. By synthesizing videos of various elements such as materials and workers with 3D images and training the system, reliability has been increased up to 95%.

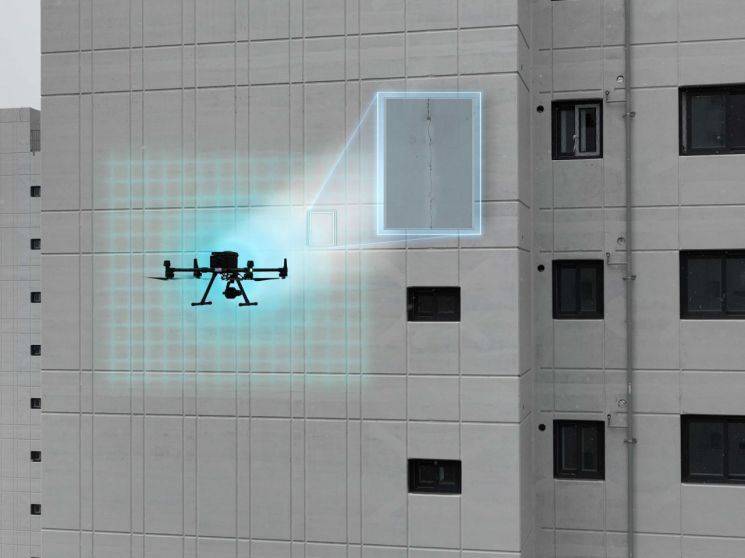

The AI crack management solution using drones is an AI crack image analysis platform developed by POSCO E&C that combines drone filming and vision AI technology, achieving a crack recognition accuracy of about 90%. It automatically detects the width and length of concrete cracks and can prioritize identification of dangerous cracks. POSCO E&C is actively applying this solution to concrete exterior wall crack inspections in apartment buildings and plans to expand its application to infrastructure such as bridges and plant structures.

In addition, POSCO E&C is developing a 'contract document review system' that uses large language model (LLM) technology like ChatGPT to automatically review essential contents in contract documents and enable Q&A in a chat format for inquiries. Along with the 'drawing automatic review system' to strengthen structural stability and ensure design quality, it is scheduled for commercialization within this year.

A POSCO E&C official said, "We plan to expand the development and application of AI technologies tailored to construction," adding, "We will actively utilize smart construction technologies that combine smart and AI to innovate construction sites."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)