50% Reduction in Carbon Dioxide Emissions

Combustion technology for MW-class ship engines using ammonia, a future renewable energy source, as fuel is being applied on-site for the first time in Korea. It is expected to accelerate competitiveness in the global eco-friendly ship engine market.

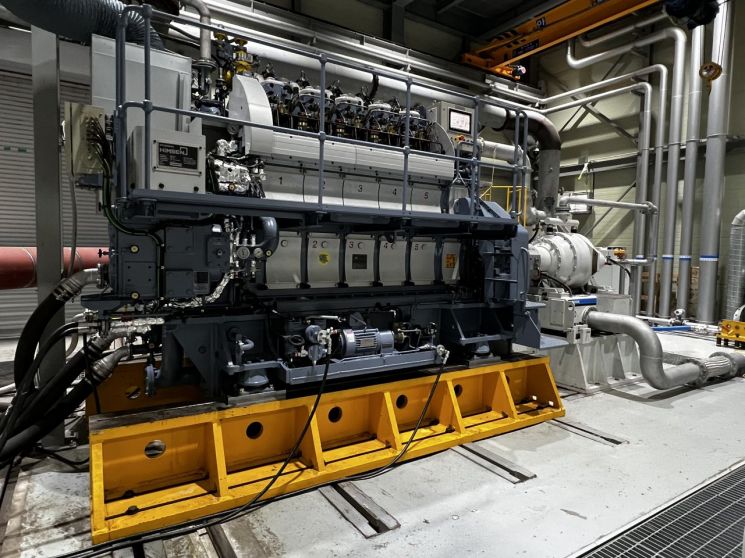

The Korea Institute of Machinery and Materials (Director Ryu Seok-hyun) announced on the 10th that the research team led by Principal Researcher Park Cheol-woong is successfully conducting a demonstration of LNG-ammonia dual-fuel engine combustion technology for ships at the Korean Register Green Ship Equipment Testing and Certification Center in Gunsan, Jeonbuk, through joint research with the Korean Register, HD Hyundai Heavy Industries, HD Korea Shipbuilding & Offshore Engineering, the Korea Research Institute of Ships and Ocean Engineering, and Gunsan University. This research was supported by the Ministry of Oceans and Fisheries’ project “Development of 2100-horsepower LNG-Ammonia Dual-Fuel Engine.”

The research team achieved high output and thermal efficiency by injecting ammonia at high pressure into the combustion chamber of the ship engine and maintaining stable combustion. Although ammonia is a promising carbon-neutral fuel, it is difficult to manage as a material for fuel supply systems due to concerns such as corrosion and toxicity. Additionally, ignition is difficult because of the high ignition energy required, and slow combustion speed increases incomplete combustion, causing a decrease in engine output and efficiency.

Senior Researcher Park Cheol-woong at the Korea Institute of Machinery and Materials is explaining the combustion technology of MW-class LNG-ammonia dual-fuel engines for ships. Photo by Korea Institute of Machinery and Materials

Senior Researcher Park Cheol-woong at the Korea Institute of Machinery and Materials is explaining the combustion technology of MW-class LNG-ammonia dual-fuel engines for ships. Photo by Korea Institute of Machinery and Materials

The demonstrated “MW-class LNG-ammonia dual-fuel engine for ships” verified its performance by preventing corrosion and external leakage of ammonia through changes in the O-ring material in the fuel supply device, enabling high-efficiency combustion and reducing carbon dioxide emissions by more than 50%.

The research team optimized the timing of ammonia fuel injection to match the combustion speed and met the ignition conditions requiring high energy. They also maximized thermal efficiency and improved output performance by directly injecting high-pressure ammonia fuel into the combustion chamber and increasing the air mixture ratio through lean combustion, while simultaneously reducing emissions to solve the problem of incomplete combustion.

Principal Researcher Park Cheol-woong of KIMM stated, “The MW-class LNG-ammonia dual-fuel engine combustion technology for ships is an independent technology that meets greenhouse gas emission regulations for ship engines and can secure leadership in the future shipbuilding market. We will strive to expand its application not only to ship engines but also to power sources such as automobiles and generators where carbon emission reduction is required.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.