Domestic researchers have succeeded for the first time in the world in developing a mass production technology for high-performance smart textiles.

KAIST announced on the 8th that Professor In-Kyu Park of the Department of Mechanical Engineering, Professor Joon-Sung Ahn of Korea University Sejong Campus, Dr. Yong-Rok Jung of the Korea Atomic Energy Research Institute, and Dr. Jun-Ho Jung of the Korea Institute of Machinery and Materials jointly developed the "metal-ceramic nano ribbon yarn manufacturing technology for smart textiles."

(From left) Professor An Junsung, Dr. Jeong Yongrok, PhD candidate Kang Mingu, Dr. Jeong Junho, Professor Park Inkyu. Provided by KAIST

(From left) Professor An Junsung, Dr. Jeong Yongrok, PhD candidate Kang Mingu, Dr. Jeong Junho, Professor Park Inkyu. Provided by KAIST

Smart textiles are future-oriented fibers that combine existing textiles with digital information technology. The functional nanofiber manufacturing processes developed so far have limitations in manufacturing with various materials, and to realize high-performance smart textiles, the development of functional metal-ceramic nanofibers with excellent electrical properties and mechanical flexibility of nanomaterials has been recognized as essential.

For the same reason, the joint research team developed a universal metal-ceramic nano ribbon fiber manufacturing platform technology to overcome the fundamental and material limitations of functional nanofibers used in smart textiles.

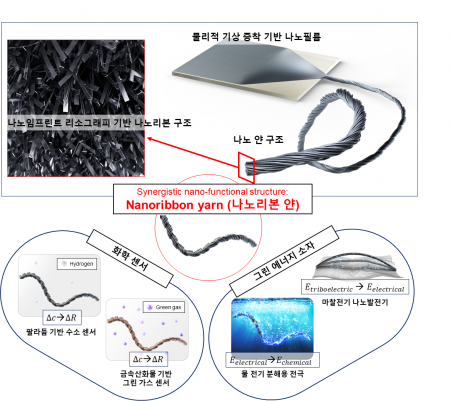

The technology developed by the joint research team obtains metal-ceramic nano ribbons suspended in the air by depositing metal on a nano mold (a substrate with nano-structured patterns made by nano imprint lithography, a process that transfers micro and nano-scale patterns onto a thin polymer film) and then etching the mold using a plasma etching process.

Additionally, by twisting bundles of nano ribbons with weakened adhesion to the substrate into yarn form, the nano ribbon yarn shape can be secured. The joint research team emphasized that this is the world's first yarn manufacturing process applicable to various inorganic materials, opening the way for mass production of high-performance smart textiles.

Yarn refers to a thread form that has a continuous strand structure by aligning natural or synthetic fibers parallel in the length direction and twisting them. It is a commonly used form in threads used for knitting and weaving.

Schematic diagram of metal and ceramic nano ribbon yarn and its application fields. Provided by KAIST

Schematic diagram of metal and ceramic nano ribbon yarn and its application fields. Provided by KAIST

In this study, the joint research team demonstrated the possibility of producing nano ribbon yarns using metals and oxides such as gold, palladium, nickel, aluminum, platinum, tungsten oxide, tin oxide, nickel oxide, indium oxide, and copper oxide.

They also confirmed that the developed nano ribbon yarns can be used not only as high-performance gas sensors capable of detecting green gases such as hydrogen and ammonia but also as green energy-related devices such as water electrolysis and triboelectric nanogenerators, the joint research team added.

The developed inorganic nanofibers are expected to overcome the limitations of existing smart textile materials and contribute to applications in medical industry, fashion industry, defense, healthcare smart textiles, and implementing the Internet of Things (IoT) in textiles.

Professor In-Kyu Park of KAIST said, "The developed metal-ceramic nano ribbon yarn manufacturing technology is expected to provide a clue to solving the essential problems of material diversity and mass production in the smart functional nanofiber manufacturing process." He added, "The joint research team plans to utilize this technology for manufacturing various nano electronic devices including sensors and energy devices, serving as a stepping stone to becoming a leading nation in nanostructure manufacturing technology and smart textile technology."

Meanwhile, Professor Joon-Sung Ahn of Korea University Sejong Campus, Dr. Yong-Rok Jung of the Korea Atomic Energy Research Institute, and Min-Koo Kang, a doctoral student in the Department of Mechanical Engineering at KAIST, participated as co-first authors in this study, which was published in the March online edition of the international journal Small.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)