'Smart Factory & Automation Industry Expo 2024' Opens

Showcasing AI-Powered Factory Automation Technologies

Domestic and International Companies Participate...Record High Visitors Expected

On the 27th, the 'Smart Factory & Automation Industry Exhibition 2024 (AW 2024)' held at COEX Exhibition Hall in Samseong-dong, Seoul, was packed with numerous visitors, befitting Asia's representative industrial exhibition. This exhibition, participated by over 500 companies, runs for three days from this day until the 29th. Visitors could see a wide range of digital transformation-related products and solutions at a glance, from factory automation components to Internet of Things (IoT) and artificial intelligence (AI)-based industrial robots.

Hanwha Robotics' robotic arm is shaking a wine bottle and glass as if it were a sommelier.

Hanwha Robotics' robotic arm is shaking a wine bottle and glass as if it were a sommelier. [Photo by Lee Seong-min]

"Your iced Americano is ready."

When ordering a drink at the kiosk, the order details appeared on the monitor. It informed that the waiting time was 2 minutes and 40 seconds. Measuring the actual time for the drink to be served showed it was quite accurate. The focus of the caf? customers' attention was not a human barista but a robotic arm. The time taken to make the drinks through robots and automation systems was predictably consistent. Customers did not have to wait endlessly for their ordered drinks.

Kim (23, male), a university student who received a robot-made drink, said, "I major in 3D product design, so I came to gain various insights," adding, "Compared to when I visited two years ago, there seem to be more booths and more people."

To the left of the coffee robot, a robotic arm decanting wine like a sommelier also caught attention. At the booth prepared by Hanwha Robotics, it was crowded with people wanting to see robots handling both coffee and wine. Hain Oh, assistant manager of the robot sales team at Hanwha Robotics, explained, "Coffee robots have already been introduced in many places, but wine robots are not yet officially released in the market," adding, "We enhanced safety by introducing a visual safety system together."

Visual safety is a system that uses dual 3D cameras to detect human movement and automatically stops the robot's operation, allowing users to set the operational range themselves. Robots equipped with visual safety were also displayed at the booth.

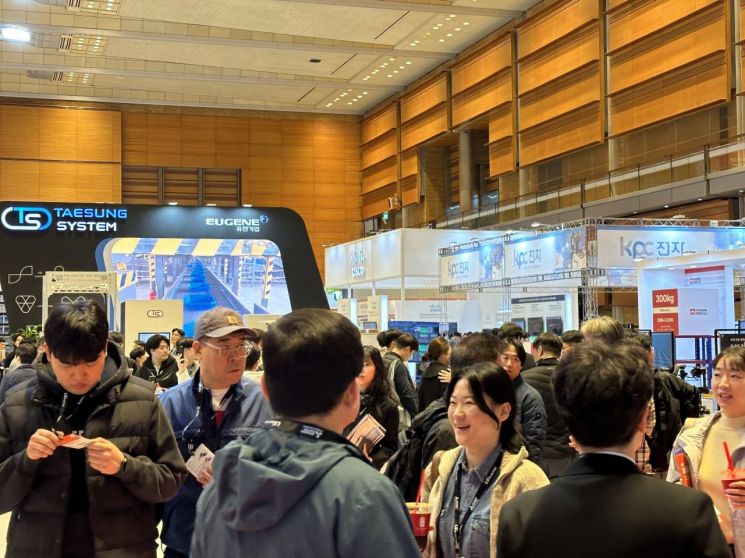

On the morning of the 27th at 10 AM, the 'Smart Factory and Automation Industry Exhibition 2024 (AW 2024)' held at COEX was crowded with people.

On the morning of the 27th at 10 AM, the 'Smart Factory and Automation Industry Exhibition 2024 (AW 2024)' held at COEX was crowded with people. [Photo by Lee Seong-min]

Marking its 34th edition this year, AW 2024 was held under the theme of a ‘Sustainable Factory,’ meaning the implementation of autonomous manufacturing technology in the manufacturing industry using artificial intelligence (AI). Global companies such as Siemens and Mitsubishi Electric Automation, as well as domestic companies like LS Electric, Hanwha Robotics, and CJ OliveNetworks, showcased smart factory solutions equipped with automation technology.

LS Electric, which set up the largest booth at this event, celebrated its 50th anniversary by presenting innovative technologies for future factories under the theme ‘Seeking Total Solutions for the New Era of Automation Industry.’ Sangcheol Ahn, manager of the technical sales team at LS Electric, said, "We are exhibiting broadly divided into devices and applications," adding, "We are introducing our logistics automation systems used in various fields such as battery manufacturing."

In the Smart Logistics Special Zone, a 'robot dog' was weaving through the large crowd. Known as a quadruped robot, the robot dog is not yet widely used in smart factories but is expected to be used for traversing difficult terrains or conducting early morning patrols, according to Rainbow Robotics.

The robot dog supports both autonomous driving and manual control modes. As the number of visitors increased in the afternoon, the robot dog, which had been avoiding people autonomously, was being operated manually by staff for safety reasons.

Manual control was possible when the controller and the robot were connected to the same Wi-Fi network. Although technology using communication networks such as LTE has been developed, it is not yet commercialized. Su-deok Hwang, team leader of sales team 3 at Rainbow Robotics, said, "Collaboration with telecom companies is necessary to use communication networks, but discussions have not progressed significantly due to differences in data transmission speeds," adding, "In the future, I believe technology will emerge that integrates sensors and communication networks to enable operation from very distant locations."

The country's first humanoid robot, 'Hubo,' which attracted great attention in the AI era, was also on display. Although it is not yet at a stage to be used in smart factories, there are expectations that it could be commercialized as AI advances. Jungwoo Heo, technical director at Rainbow Robotics, said, "Ultimately, the most important factor for robots to replace humans is intelligence," adding, "If that level of intelligence, that is, AI technology, supports it, robots will eventually be able to perform all tasks that humans do on site."

The massive container belt and autonomous mobile robots (AMR) created by CJ OliveNetworks also caught visitors' eyes. Among them, a service that sorts parcels in collaboration with Chinese equipment manufacturer Weijim was central. The service recognizes unique QR codes on each parcel and sorts them according to user-defined conditions. It provides customized sorting technology based on parcel size, weight, and region.

Inwoo Kim, manager of the manufacturing logistics business team at CJ OliveNetworks, explained, "Our strength lies in the extensive references accumulated based on our experience with internal businesses such as CJ Logistics and CJ Olive Young." He added that since many companies offer similar services, competitiveness must ultimately be secured through details, references, and pricing.

More than 60,000 visitors had completed pre-registration by the day before the event opened. The organizers forecast that the scale of visitor attendance, as well as the number of participating company booths, will set a record high.

Kang Kyung-sung, the first vice minister of the Ministry of Trade, Industry and Energy, who visited the site that day, said, "Digital transformation (DX) is a key technology that can compensate for the shortage of on-site workers amid a declining working-age population," adding, "Since Korea has considerable technological capabilities in the manufacturing sector, we will focus on upgrading systems by introducing AI here."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.