Addition of 'Aircraft Engine Manufacturing' to Business Objectives

Doosan Enerbility announced on the 27th that it will officially begin developing aircraft engines based on its capabilities in developing gas turbines for power generation.

At the regular shareholders' meeting held the day before, Doosan Enerbility added "manufacturing aircraft engines, producing auxiliary propulsion system parts, maintenance, sales, and service business" to its business objectives. Taking this opportunity, the company plans to accelerate the development of aircraft engines, especially for unmanned aerial vehicles (UAVs).

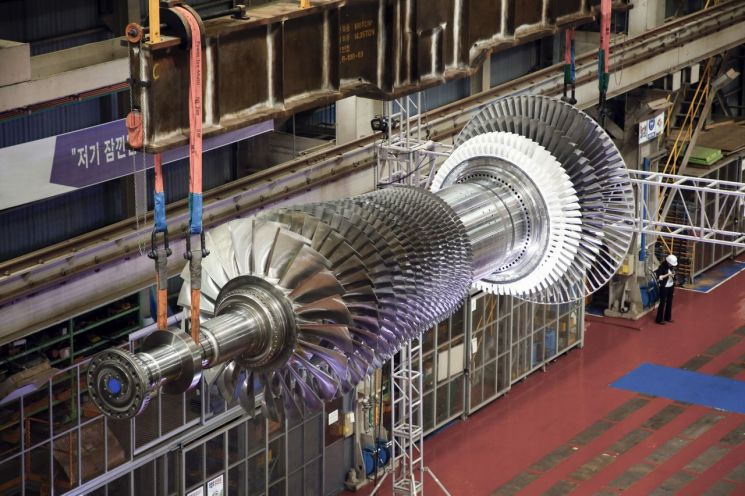

The power generation gas turbines and aircraft engines developed by Doosan Enerbility share the same technological foundation, with similar structures and operating principles.

Aircraft gas turbines play a role in securing thrust (the force that pushes an object in the direction of motion) for flying vehicles. The key factors are high output, lightweight, and operational flexibility. Power generation gas turbines require higher efficiency, higher output, and greater stability than aircraft gas turbines.

A model of Doosan Enerbility's hydrogen turbine showcased at the world electronics and IT exhibition 'CES 2024' held in Las Vegas, USA, in January this year. Doosan Enerbility is developing a hydrogen turbine based on a power generation gas turbine, which it successfully developed as the fifth in the world, and has also officially launched a drone aircraft engine development project with a similar structure and operating principle.

A model of Doosan Enerbility's hydrogen turbine showcased at the world electronics and IT exhibition 'CES 2024' held in Las Vegas, USA, in January this year. Doosan Enerbility is developing a hydrogen turbine based on a power generation gas turbine, which it successfully developed as the fifth in the world, and has also officially launched a drone aircraft engine development project with a similar structure and operating principle. [Photo by Doosan Enerbility]

Doosan Enerbility plans to utilize the know-how accumulated in design, manufacturing technology, and material technology during the development of large gas turbines for power generation in the development of aircraft engines.

When igniting an aircraft engine, technology capable of withstanding ultra-high temperatures of 1500 degrees Celsius inside the engine is required, and the company has already secured cooling and coating technologies that overcome high-temperature environments of 1680 degrees Celsius.

In addition, it possesses differentiated advantages such as ▲core material development capabilities including high-temperature components ▲various intellectual properties (IP) and databases accumulated during its own development process ▲in-house design, manufacturing, and testing infrastructure ▲and advanced engineering capabilities.

Doosan Enerbility's aircraft engine business has already begun.

Currently, it is participating in the "10,000 lbf class (thrust of 10,000 pounds-force) gas turbine engine development for unmanned aerial vehicles" project led by the Agency for Defense Development. In this project, which consists of three tasks, Doosan Enerbility is responsible for two tasks considered the most challenging and core technologies: "engine layout design and component analysis" and "casting and post-processing of turbine vanes and blades," performing the basic design until 2027.

It is also conducting conceptual design for advanced aircraft engines commissioned by the government to secure domestic fighter jet engine technology. Advanced aircraft engine technology is included in the Ministry of Science and ICT's 12 national strategic technologies and the Ministry of National Defense's 10 defense strategic technologies, highlighting its importance from economic and security perspectives.

Seungwoo Son, Vice President of Doosan Enerbility Power Service BG, said, "Doosan's competitiveness lies in having both physical and human infrastructure along with the experience of directly developing, manufacturing, and supplying power generation gas turbines as an original equipment manufacturer (OEM). We will actively utilize this to contribute to the localization of aircraft engines and lay the foundation for entering overseas markets."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)