Domestic researchers have developed a technology for producing key industrial raw materials in the chemical field that reduces carbon emissions by utilizing oleaginous yeast.

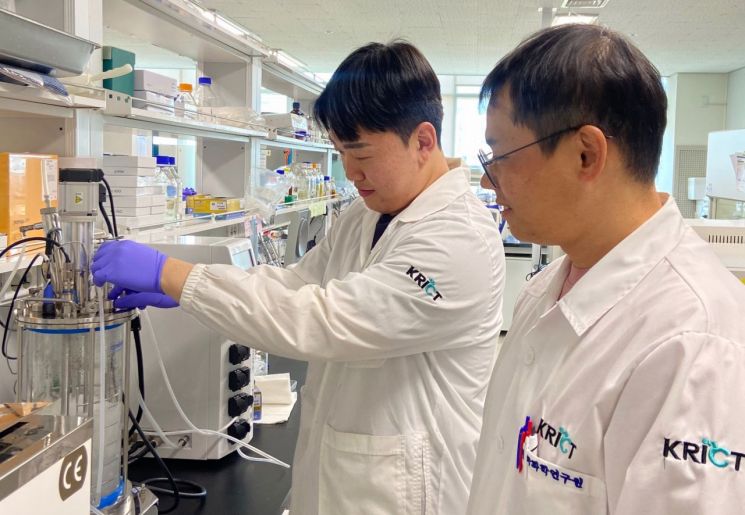

Culturing the microbial cell factory strain 'Yarrowia lipolytica' for bio adipic acid production. Photo by Korea Research Institute of Chemical Technology

Culturing the microbial cell factory strain 'Yarrowia lipolytica' for bio adipic acid production. Photo by Korea Research Institute of Chemical Technology

The Korea Research Institute of Chemical Technology (President Young-Kuk Lee) announced on the 18th that the research team led by Dr. Baek Seung-ho and Dr. Noh Myung-hyun successfully developed a microbial cell factory for producing bio adipic acid using Yarrowia lipolytica, an oleaginous yeast used as an industrial microorganism. Oleaginous yeast refers to yeast with excellent ability to accumulate fat or oil in the body.

This achievement is a technology that produces bio adipic acid from biomass by utilizing synthetic biology technology. Synthetic biology technology has been selected as a key technology in the 'Advanced Bio' field among the '12 National Strategic Technologies' announced by the government. By applying this technology, adipic acid is expected to be widely used in clothing, daily life, and industrial application product areas where it serves as a major chemical material.

Adipic acid is an essential intermediate raw material for nylon fibers and a core chemical material used for various purposes such as biodegradable plastic raw materials and food additives. Most adipic acid is produced from fossil fuels such as naphtha and natural gas, but since nitrous oxide (N2O) generated during the production process causes the greenhouse effect, the development of environmentally friendly and sustainable bio adipic acid production technology is essential.

Recently, as environmental regulations and demands for carbon emission reduction have increased, movements to replace with carbon-neutral bio-chemical raw materials are spreading, but the technologies developed so far have many points to be supplemented for commercialization, such as using pathogenic microorganisms that can cause diseases in the human body or difficulties in genetic manipulation.

Accordingly, the research team developed the world's first technology to produce adipic acid by utilizing Yarrowia lipolytica, an oleaginous yeast designated as a Generally Recognized As Safe (GRAS) food additive by the FDA, as a microbial cell factory. The completed microbial cell factory is an eco-friendly technology that selectively decomposes and converts fatty acid-derived substances through microbial cultivation processes to efficiently produce bio adipic acid. As a core technology to replace petrochemical-based adipic acid, it is expected to be applicable in various fields in the future.

President Young-Kuk Lee said, “We hope this achievement will contribute to securing Korea’s core technology for bio-material production in the future.”

The research results were published in the January issue of Bioresource Technology (IF: 11.4), a prestigious journal related to biomass.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)