'Closed Loop System V2' Integrating Eco-Friendly Technology

From Global No.1 Cathode Material Company to Integrated Secondary Battery Material Company

Ecopro will consecutively participate in battery events in Korea and Japan to unveil the blueprint of the 'Closed Loop System (CLS) V2,' which reduces manufacturing costs by more than 30%.

On the 29th, Ecopro announced that it participated in the '9th Battery Summit Tokyo 2024' held in Tokyo, Japan, on the 27th. The Battery Summit is a global battery event hosted by resource information provider MIRU and Japanese energy companies. This year, Dr. Akira Yoshino, who won the Nobel Prize in Chemistry for developing lithium-ion batteries, also participated.

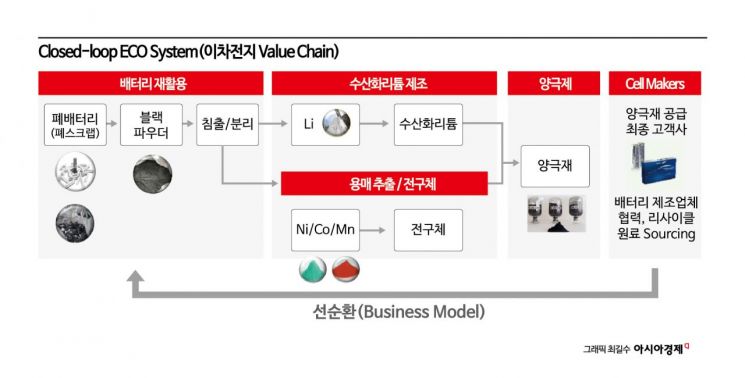

Ecopro introduced the advanced Closed Loop System V2, which integrates eco-friendly elements into the existing Closed Loop System. The Closed Loop System is a system Ecopro implemented on a 120,000-pyeong site at its Pohang campus with an investment of 2 trillion KRW, realizing the entire secondary battery cathode material production process?from recycling waste batteries to raw materials, precursors, and cathode materials?in a single location. It is regarded as the core technology that propelled Ecopro to become the global No. 1 cathode material company. Battery companies and automakers both domestically and internationally have benchmarked this system.

The Closed Loop System V2 is an advanced version of the existing system, incorporating various eco-friendly technologies. Jang Jeheon, Director of Marketing at Ecopro, said, "Ecopro was the first to integrate the entire battery material production process in one place to create an ecosystem, so there was great interest in the construction process and operational know-how."

Ecopro plans to showcase the Closed Loop System V2 at 'InterBattery 2024,' held from the 6th to the 8th of next month at COEX in Gangnam-gu, Seoul, focusing on expanding the scope of waste battery recycling and purifying and reusing industrial wastewater.

Ecopro has decided to gradually expand the collection and reuse of waste batteries to the cell, module, and pack process stages. The battery manufacturing process is divided into the stages of 'raw materials (materials) → electrodes (cathode materials, etc.) → battery cells → battery modules → battery packs.' In the existing Closed Loop System, only scrap and black mass (high-purity recycled mineral powder) generated during the electrode manufacturing process were usable. The industrial wastewater recycling sector aims for 'zero waste water' by decomposing wastewater generated in the material manufacturing process and reusing it in the process or processing it into other materials for commercialization.

Through the Closed Loop System V2, Ecopro plans to significantly reduce the generation of Na2SO4 (sodium sulfate) to lower manufacturing costs. By expanding the scope of waste battery recycling, it aims to minimize mineral mining, which causes environmental pollution, and contribute to improving the natural circulation system by recycling industrial wastewater while also reducing costs involved in the process. Ecopro stated, "In addition, we will unveil future business items such as sodium cathode materials, silicon anode materials, and all-solid-state batteries, revealing our business vision to transform from the global No. 1 cathode material company into an 'integrated secondary battery materials company.'"

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.