Korea Institute of Fusion Energy Achieves Triple Lithium Extraction Compared to Previous Methods

A research result has emerged that significantly improves the extraction efficiency of lithium, one of the important mineral resources, by utilizing plasma technology.

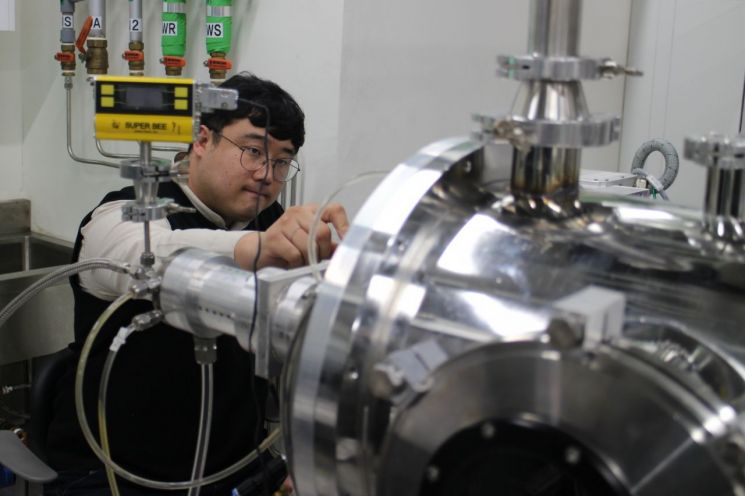

The Korea Institute of Fusion Energy (Director Yu Seok-jae) announced on the 1st that researchers at the Plasma Technology Research Center applied carbon dioxide (CO2) microwave plasma technology to the lithium extraction process and succeeded in extracting three times more lithium compared to the conventional lithium extraction method.

Lithium is typically extracted by mixing sodium carbonate (Na2CO3) with brine containing lithium to form lithium carbonate (Li2CO3), which is a compound of lithium and carbon dioxide. This method has the disadvantage of requiring an additional process to remove sodium impurities mixed in the extracted lithium carbonate.

As an alternative, a lithium extraction method that injects carbon dioxide gas into the brine instead of sodium carbonate is being used, but this method also has the problem of low extraction rates in brine where lithium salts combined with chlorine exist.

Dr. Kim Ji-hoon and Dr. Yang Jong-geun from the Fusion Research Institute utilized carbon dioxide microwave plasma technology, which ionizes carbon dioxide and treats it in a plasma state, to improve the efficiency of the lithium extraction method using carbon dioxide. When the research team conducted comparative experiments using simulated brine to compare the efficiency of the lithium extraction method using carbon dioxide plasma with the conventional method, the experiment using plasma technology showed about three times higher extraction efficiency.

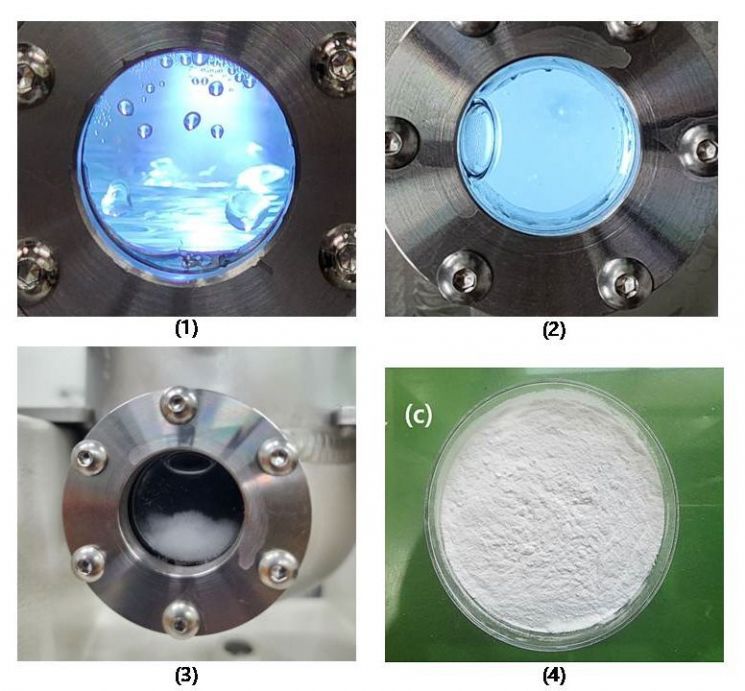

Lithium mineral carbonation process using plasma.

Lithium mineral carbonation process using plasma.(1) Carbon dioxide plasma treatment of simulated brine containing lithium

(2) White solid material (lithium carbonate) formed through the mineral carbonation process of the simulated brine

(3) Precipitated lithium carbonate after completing plasma treatment

(4) Lithium carbonate powder obtained by filtering the solution in (3)

The lithium extraction rate in the experiment directly injecting carbon dioxide gas was only 10.3%, but in the experiment treated with carbon dioxide plasma, the lithium extraction rate reached 27.87%.

This study is the first to confirm improved extraction efficiency by applying plasma technology to the lithium extraction process compared to conventional methods. The related research paper* was published in DESALINATION (IF 9.9), a prestigious journal in the field of water resources.

*Paper title: Novel approach for recovering lithium from simulated aqueous solutions using carbon dioxide microwave plasma (‘23.12)

Dr. Yang Jong-geun, the first author of the paper, said, “Through this study, we confirmed that the heat of the plasma and the ions, electrons, and radicals constituting the plasma during carbon dioxide plasma generation affect the lithium extraction efficiency,” and added, “We plan to further expand research on plasma lithium extraction processes through additional studies on the effects of carbon dioxide plasma.”

The research team expects that the lithium extraction process using plasma could be a new approach for developing technology that efficiently extracts lithium even from seawater, which has a lower lithium concentration than the salt lakes where lithium extraction currently takes place.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.