Professor Jogye-yong's Team Coats Battery Separators with Ultrafine Silica Nanoparticles

A research team at the National Pukyong University has developed a technology to enhance the lifespan and safety of next-generation lithium batteries.

On the 1st, National Pukyong University announced that Professor Jo Gye-yong's research team (majoring in Industrial Chemistry) succeeded in developing a separator coating technology that extends the lifespan and improves the safety of lithium metal anodes used in lithium metal batteries.

According to National Pukyong University, the research team, consisting of Professor Jo Gye-yong, Master’s researcher Park Jae-won, doctoral candidate Kwon Young-je, and Professor Yoon Jeong-sik from Incheon National University (Department of Energy Chemical Engineering), developed an interface control technology for separators that suppresses lithium dendrite formation on lithium metal anodes.

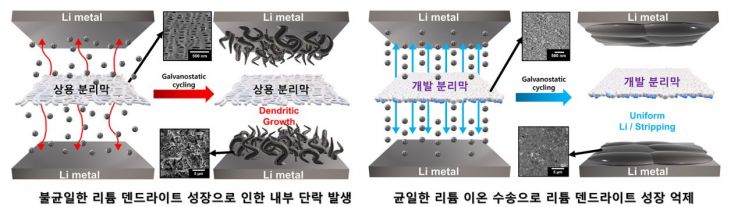

Schematic diagram of lithium dendrite suppression on lithium metal anode through SiO2 nanoparticle coating.

Schematic diagram of lithium dendrite suppression on lithium metal anode through SiO2 nanoparticle coating.

The research team succeeded in suppressing the formation of lithium dendrites, which threaten the safety of lithium metal batteries, by surface modification of polypropylene separators using fluorine-based polymers and coating with ultra-thin silica (SiO2) nanoparticles.

Lithium metal anodes are attracting attention as next-generation anodes capable of realizing high capacity in lithium batteries, but dendrites originating from the lithium metal surface cause rapid lifespan degradation and pose a risk of fire by penetrating the separator and triggering thermal runaway.

Although research on suppressing lithium dendrites is actively underway, existing inorganic particle coatings using binders have issues such as uneven coating layers, difficulty forming ultra-thin layers, and detachment of inorganic particles.

Professor Jo Gye-yong’s team developed a method to coat silica nanoparticles very thinly and uniformly by controlling the separator interface based on fluorine-based polymers.

The newly developed ultra-thin SiO2 nanoparticle coating layer was coated very thinly (200 nm) and uniformly with high density. This made the transport of lithium ions through the separator uniform, suppressing dendrite growth caused by overvoltage due to local lithium ion deficiency.

In addition to improving mechanical properties through silica nanoparticle coating, the separator showed excellent high-temperature safety characteristics by suppressing thermal shrinkage of the separator at high temperatures (140°C).

Professor Jo Gye-yong's team. (Top row from left: Professor Yoon Jeong-sik, Bae Ji-woo, Kaiyun Zhang, Choi Kyung-min, Kwon Young-je, Lee Min-jung; bottom row from left: Kim Se-hoon, Professor Jo Gye-yong, Park Jae-won)

Professor Jo Gye-yong's team. (Top row from left: Professor Yoon Jeong-sik, Bae Ji-woo, Kaiyun Zhang, Choi Kyung-min, Kwon Young-je, Lee Min-jung; bottom row from left: Kim Se-hoon, Professor Jo Gye-yong, Park Jae-won)

Park Jae-won, the first author of the study, said, “We expect that the development of high-performance separators for next-generation lithium metal batteries will solve the major safety issues of secondary batteries and contribute to accelerating the commercialization of lithium metal anodes.”

This research was conducted with support from the Ministry of Trade, Industry and Energy and the Research Foundation’s Excellent New Research Project. The research paper titled “Ultra-thin SiO2 Nanoparticle Layered Separators by a Surface Multi-functionalization Strategy for Li-Metal Batteries: Highly Enhanced Li-Dendrite Resistance and Thermal Properties” was published on February 1 in the international journal Energy Storage Materials (IF 20.4 / JCR top 2.95%).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.