Withstands flames at 1500℃... Industry's highest level

Manufacturing process using tape-form lamination method

LG Chem has succeeded in developing a battery 'thermal runaway' delay material that can withstand flames at 1500℃ for more than 20 minutes.

Thermal runaway, a major cause of electric vehicle battery fires, is a phenomenon where heat is generated as stress is applied to battery cells due to various causes. Thermal runaway has been cited as one of the factors delaying the popularization of electric vehicles.

On the 27th, LG Chem announced that it had developed a 'special flame-retardant thermoplastic continuous fiber composite material (special flame-retardant CFT)' in collaboration with LX Hausys. The special flame-retardant CFT solved the heat and pressure of thermal runaway, which was difficult to withstand with conventional plastics alone. This material can withstand strong flames and high pressure for more than 14 times longer than existing composite materials.

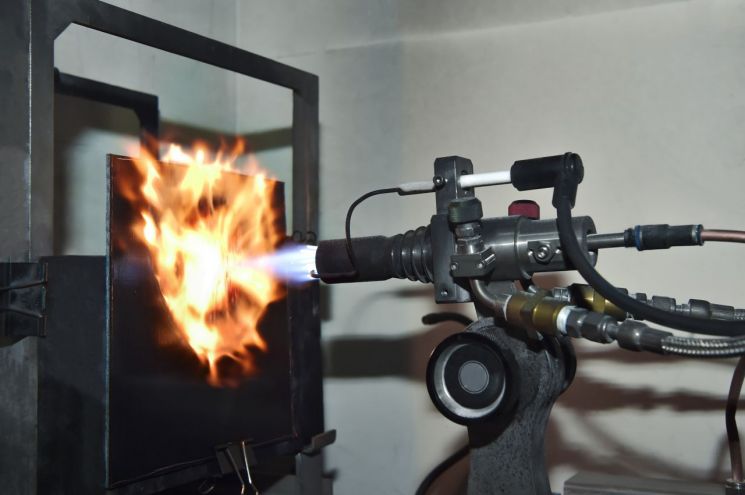

The special flame-retardant CFT developed by LG Chem and LX Hausys did not melt, drip, or develop holes even after 20 minutes when heat and pressure above 1500℃ were applied to a thin 1.6mm thick special flame-retardant CFT, according to LG Chem's own torch test results. This is an industry-leading level of flame blocking performance.

Test scene of 'Special Flame-Retardant CFT' that withstands heat and pressure above 1500℃ for more than 20 minutes

Test scene of 'Special Flame-Retardant CFT' that withstands heat and pressure above 1500℃ for more than 20 minutes [Photo by LG Chem]

The special flame-retardant CFT incorporates LG Chem's thermal runaway delay material technology and LX Hausys's thermoplastic composite material (Continuous Fiber Thermoplastics·CFT) manufacturing technology. The thermal runaway delay material developed by LG Chem last year blocked flames for more than 10 minutes at over 1000℃, the longest time in the world at that time. LX Hausys improved the blocking performance by using a manufacturing process that laminates LG Chem's material in tape form.

The special flame-retardant CFT is rigid and has low deformation under force (high stiffness), making it suitable for use in large battery pack top and bottom covers among electric vehicle battery components. It is expected to effectively delay the spread of flames in the event of an electric vehicle fire, helping secure time needed for driver evacuation and fire suppression.

LG Chem has been conducting research and development on thermal runaway delay materials since 2009. It completed material development last year and established a mass production system. The thermal runaway delay material, which allows for precise molding, is mainly used in battery modules. The special flame-retardant CFT developed this year is used for large battery pack covers that wrap the modules, so when both materials are used together, they can doubly prevent the spread of flames.

Shin Jaemyung, head of the Marketing Division of LG Chem's Engineering Materials Business Unit, said, "Since announcing the development of the battery thermal runaway delay material last year, we have been working closely with LX Hausys. We are proud to have a comprehensive solution lineup including delay materials, glass mats, and CFT for electric vehicle thermal runaway."

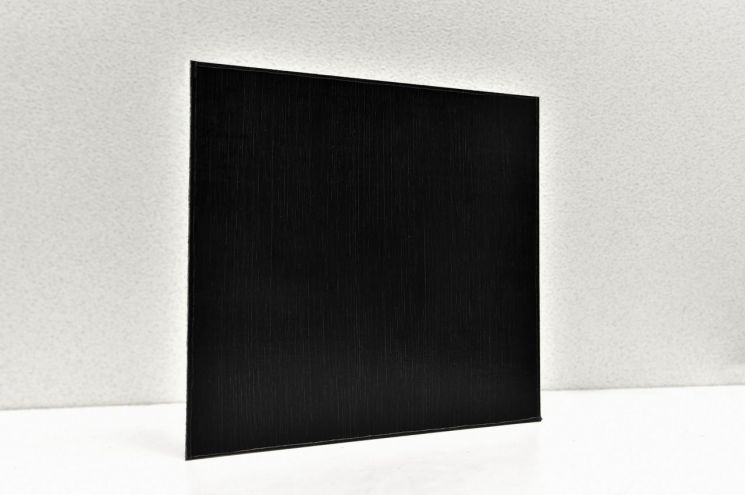

Battery thermal runaway delay material 'Special Flame-retardant CFT' jointly developed by LG Chem and LX Hausys [Photo by LG Chem]

Battery thermal runaway delay material 'Special Flame-retardant CFT' jointly developed by LG Chem and LX Hausys [Photo by LG Chem]

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.