Introduction of Advanced Technologies Considering Sustainability and Work Efficiency

Expansion of Plastic Alternative Material Discovery

"Not a Choice but a Necessity"... Spread Among Domestic Food Companies

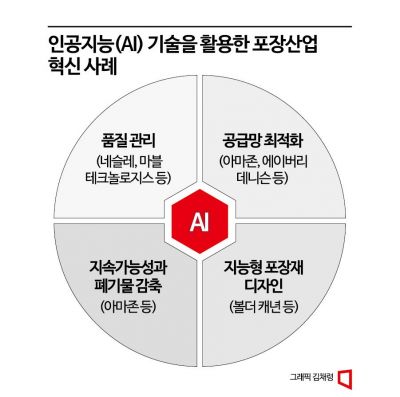

Global distributors are focusing on enhancing sustainability and operational efficiency in the packaging industry, the final stage of product completion. By integrating artificial intelligence (AI) technologies such as machine learning and robotic automation, they perform product packaging and delivery tailored to consumer characteristics, expanding their efforts toward eco-friendly management that minimizes packaging waste.

CJ CheilJedang's stick-type 'Bibigo Gim Snack,' which replaced the plastic tray used as internal packaging with paper [Photo by CJ CheilJedang]

CJ CheilJedang's stick-type 'Bibigo Gim Snack,' which replaced the plastic tray used as internal packaging with paper [Photo by CJ CheilJedang]

According to global market research firm Mintel on the 26th, global food company Nestl? has introduced AI technology into the quality control system of its production line and established automated processes. Based on data collected from this system, they maintain product quality, reduce failure rates, improve energy efficiency, and find ways to save water consumption. Nestl? analyzed that "after applying the AI-based quality control system, waste decreased by 15%, and efficiency increased by 60%."

The world's largest e-commerce company Amazon uses AI to optimize supply chains such as packaging and logistics delivery. By analyzing vast customer data, product characteristics, and delivery requirements, they find efficient packaging and routes, which are used to shorten delivery times and reduce waste. Through AI, Amazon has also achieved a 36% reduction in the weight per shipped item over the past six years while reducing the materials used in packaging.

Global distribution companies are actively replacing packaging materials with eco-friendly materials that can substitute plastics, in addition to adopting advanced technologies. Representative products include paper packaging materials enhanced with water-soluble coatings to improve durability and heat resistance, applied to containers, cups, and straws. Market research firm Global Information (GII) forecasts that the global paper packaging market will grow from $371.8 billion (approximately 475 trillion KRW) in 2022 to $462.6 billion (approximately 591 trillion KRW) by 2028. Indonesian startup Evoware and U.S. eco-friendly material company Loliware have respectively introduced edible products such as natural packaging and straws made from seaweed.

Domestic food companies are also following this trend. CJ CheilJedang replaced the plastic tray used as internal packaging with paper when launching the stick-type 'Bibigo Gim Snack' in the UK last October, reflecting the environmentally conscious European consumer trend.

Ottogi recently applied 'Circular Recycled PET (CR-PET)' jointly developed with SK Chemicals to meat sauce packages such as pork cutlet sauce, sesame pork cutlet sauce, and steak sauce. This is a chemical recycling method that breaks down waste plastic to the molecular level and reuses it as raw material. Earlier, in June last year, Ottogi became the first in the domestic ramen industry to apply eco-friendly packaging made with 'Flexo' printing equipment. Flexo printing uses eco-friendly water-based ink with embossed printing, reducing ink usage by more than 30% compared to conventional methods, and the company explained that it can reduce annual ink and organic solvent usage by up to approximately 1,600 tons.

An Ottogi representative stated, "As damage from recent abnormal weather events has surged, voices raising awareness of the seriousness of climate change are growing louder. We deeply empathize with the need to reduce greenhouse gas emissions and save energy, and we will continue company-wide efforts throughout our business operations."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)