Improving Membrane Panel Bonding Speed

Enhancing LNG Cargo Hold Production Efficiency

Expanding Application to Liquefied Hydrogen Cargo Holds

Samsung Heavy Industries announced on the 21st that it has developed the industry's first 'laser high-speed welding robot.'

Through the laser high-speed welding robot, Samsung Heavy Industries has dramatically improved the welding speed of membrane panels in LNG carrier cargo tanks. It is up to five times faster than the existing Plasma Arc Welding (PAW) method.

When welding a 2m-long membrane panel, plasma arc welding takes about 5 minutes, whereas laser welding finishes in just 1 minute. The increased speed can significantly enhance the productivity of the LNG cargo tank process.

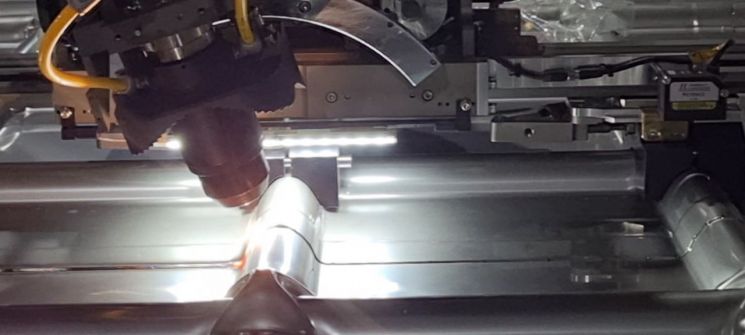

The membrane laser high-speed welding robot is performing a swing motion to automatically weld the curved areas.

The membrane laser high-speed welding robot is performing a swing motion to automatically weld the curved areas. [Photo by Samsung Heavy Industries]

The LNG cargo tank construction process is broadly divided into insulation installation and membrane construction. Among these, membrane panel construction, which comes into direct contact with cryogenic liquefied natural gas, is a high-difficulty welding task that is complicated and time-consuming. The total welding length of the four membrane panels installed on a 174,000㎥ LNG carrier reaches 60 km, equivalent to the straight-line distance from Seoul to Pyeongtaek.

Since 2021, Samsung Heavy Industries' Production Technology Research Center has been developing a high-speed welding robot optimized for membrane cargo tanks by applying the technical characteristics of laser welding. This is because securing skilled welding personnel has become increasingly difficult, and the existing plasma arc welding had limitations in productivity improvement.

The laser high-speed welding robot can generate a wide weld bead by using wobble, which rotates the laser beam at a constant interval and speed, and defocusing, which changes the focal position. It is equipped with a laser displacement sensor that can automatically detect curved welding positions.

The membrane laser high-speed welding robot developed by Samsung Heavy Industries for the first time in the industry

The membrane laser high-speed welding robot developed by Samsung Heavy Industries for the first time in the industry [Photo by Samsung Heavy Industries]

Last month, Samsung Heavy Industries successfully completed a test applying the laser high-speed welding robot to the Korean-type LNG cargo tank (KC-2C). After completing the application test for the French GTT LNG cargo tank (MK-Ⅲ) within the year and obtaining final approval from the client, it plans to fully apply the technology to production.

Choi Doo-jin, head of Samsung Heavy Industries' Production Technology Research Center, said, "The laser high-speed welding robot will be a core technology that can maintain overwhelming competitiveness in the key process of LNG carrier cargo tank construction," adding, "We plan to expand its application to cargo tanks for ultra-low temperature liquefied hydrogen carriers in the future."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.