Energy Technology Research Institute Develops High-Purity Methane Conversion Technology from Biogas

"Practical Energy Resource Utilization Becomes Possible"

A technology that converts large amounts of organic waste resources generated domestically, such as food waste and livestock manure, into high-quality biogas has been developed and entered pilot operation. Although similar facilities have existed before, the quality of the produced gas was low, reducing their effectiveness. This development is attracting attention as it opens the way for practical energy resource utilization, moving away from the current reality where most food waste is used as compost.

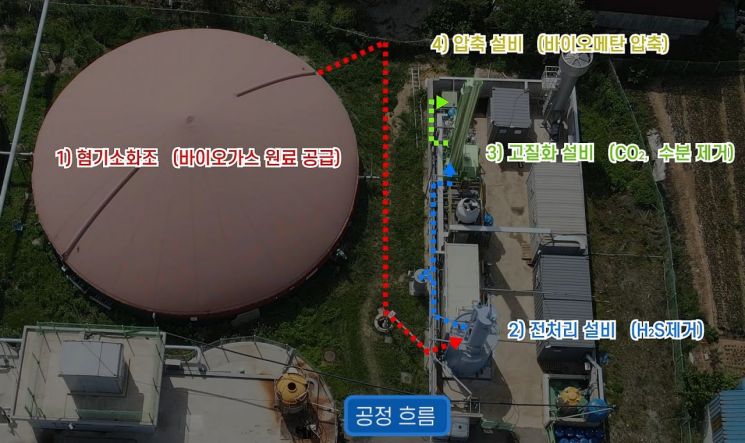

Eupjeongae Agricultural Cooperative Corporation Biogas Chronic Equipment, Photo by Korea Institute of Energy Research.

Eupjeongae Agricultural Cooperative Corporation Biogas Chronic Equipment, Photo by Korea Institute of Energy Research.

On the 11th, the Korea Institute of Energy Research announced that Dr. Kim Seon-hyeong's research team at the Clean Fuel Research Laboratory, in collaboration with the private company Ecobio Holdings, developed a technology that converts biogas containing high concentrations of hydrogen sulfide into high-purity methane. They also succeeded in pilot-scale field demonstration, increasing the possibility of commercialization.

Biogas is a gas generated by the anaerobic digestion of organic waste resources such as sewage sludge, manure, livestock manure, food waste, and animal and plant residues by microorganisms in the absence of air. As the living standards of the public improve, the amount of organic waste that can be utilized as biogas, such as food waste, is rapidly increasing. As of 2019, the amount generated was 65.37 million tons, a 14.7% increase compared to 2010.

However, the current utilization rate of energy resources is only 5.7%. Most of it is simply decomposed and used as compost or liquid fertilizer. Even this causes soil and water pollution and outbreaks of infectious diseases, necessitating long-term and environmentally friendly treatment. The government enacted related laws at the end of last year to increase the utilization of organic waste resources, mandating that up to 80% or more be gradually produced as biogas by 2050. This will be enforced from December 31 this year, and penalties will be imposed for failure to meet the targets.

Biogas mainly consists of methane (45-65%), carbon dioxide (35-55%), and hydrogen sulfide. Removing hydrogen sulfide allows it to be used for power generation and heating. If carbon dioxide is also removed, high-purity methane gas similar to natural gas can be produced, enabling its use in city gas and transportation sectors.

The research team developed a technology that removes hydrogen sulfide, carbon dioxide, and moisture from biogas to produce high-purity biomethane with over 97% purity. It can remove high concentrations of hydrogen sulfide in the thousands of ppm at low cost, making it an optimized technology for the biogas industry in Southeast Asia.

The biogas purification process consists of a pretreatment process that converts hydrogen sulfide, which causes odor and corrosion, into bio-sulfur through a microbial method, and a purification process that removes carbon dioxide and moisture by water absorption to produce biomethane. In the pretreatment process, an alkaline solution is used to remove high concentrations of hydrogen sulfide, and the solution is regenerated through microbial oxidation reactions, enabling economical operation. Notably, it showed excellent performance by almost completely removing hydrogen sulfide from biogas containing more than 4,000 ppm of high-concentration hydrogen sulfide, similar to the properties of biogas in Southeast Asia. Additionally, bio-sulfur that can be used as fertilizer is also produced.

In the purification process, the equipment is divided into several sections and packaged for easy transport and installation, allowing overseas shipment. The process removes carbon dioxide by contacting environmentally friendly and safe water under high pressure and removes moisture through adsorption technology to produce high-purity biomethane. A pilot facility was installed to conduct a demonstration process treating an average of 3 tons of biogas per day. As a result, when applied to biogas containing high concentrations of hydrogen sulfide, it successfully produced stable high-purity methane of over 97%, and obtained certification from the Korea Testing Laboratory for the experimental results.

Dr. Kim said, “The production volume and characteristics of biogas vary greatly depending on raw materials and operating conditions, but the developed technology can handle a wide concentration range of hydrogen sulfide and carbon dioxide, making it applicable to various biogas facilities and capable of stably producing high-purity methane. The developed technology is simple in operation, maintenance, transport, and installation, making it optimized for palm oil industry sites in Southeast Asia where infrastructure is lacking. We plan to attempt entry into the overseas palm oil industry sector in the future.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.