KERI Develops World's First Nano 3D Printing Technology

A world-first technology has been developed that replicates the physical phenomena behind the chameleon's ever-changing skin color and the peacock's beautiful feather colors using nano 3D printing, enabling applications in transparent displays and augmented reality (AR) devices.

Peacock Photo by Getty Images Bank

Peacock Photo by Getty Images Bank

The Korea Electrotechnology Research Institute (KERI) announced on the 7th that the Smart 3D Printing Research Team led by Pyo Jae-yeon succeeded in implementing a three-dimensional diffraction grating capable of controlling the path of light based on 'nano 3D printing technology.' This new technology applies the principle of structural color observed in nature to advanced display technologies.

When light encounters tiny microstructures on the scale of wavelengths (ranging from 1/100 to 1/1000 the thickness of a human hair), it diffracts and changes its path. If these microstructures are arranged regularly, diffraction causes reflection of light at specific wavelengths, producing colors known as 'structural colors.' For example, the chameleon's skin color changes not due to pigments but by altering the skin's microstructure to change structural color, and the peacock's feathers display beautiful structural colors due to the characteristic arrangement of their internal microstructures.

The research team realized a 'diffraction grating' capable of finely controlling structural colors using nano 3D printing technology. A diffraction grating is a device that arranges microstructures such as parallel lines regularly to control light diffraction. When light is shone on it, the light reflects along different paths depending on the wavelength, producing structural colors or spectra. In other words, this technology uses 3D printing to control light and precisely reproduce nature's beautiful structural colors without dyes.

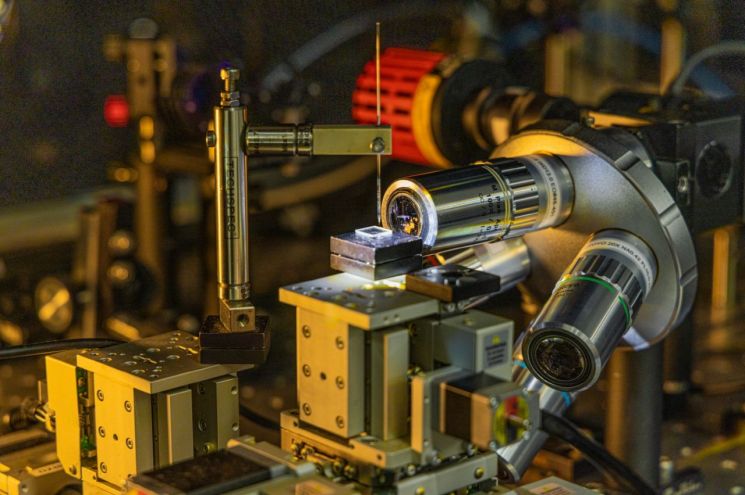

Nano Photonic 3D Printer Used for Fabricating Diffraction Gratings for Advanced Displays. Photo by KERI

Nano Photonic 3D Printer Used for Fabricating Diffraction Gratings for Advanced Displays. Photo by KERI

To control light diffraction at wavelengths as small as 1/1000 the thickness of a human hair, extremely fine diffraction gratings are required. The research team succeeded in printing high-density nano-line diffraction gratings using a new approach called 'Lateral printing' with world-class nano 3D printing technology. This method moves the 3D printing nozzle like sewing to print multiple lines in a bridge-shaped diffraction grating.

The diffraction gratings developed this time are expected to have many applications in advanced display fields. Focusing on the transparency of the diffraction grating itself, it can be used in future transparent display areas such as smart windows, mirrors, and automotive head-up displays. Additionally, it can be widely applied to augmented reality (AR) devices, which already use diffraction gratings as core components. Furthermore, since diffraction gratings can be designed to exhibit different colors depending on deformation, they can be used in mechanical engineering and biomedical fields where deformation detection is necessary, and also serve as tools for various optical physics research.

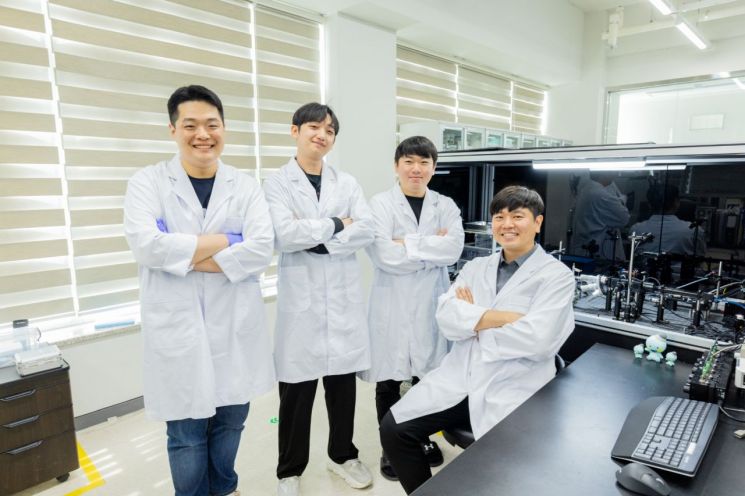

Dr. Jae-Yeon Pyo (right) and the KERI research team have developed a nano 3D printing technology for fabricating diffraction gratings used in advanced displays. Photo by KERI

Dr. Jae-Yeon Pyo (right) and the KERI research team have developed a nano 3D printing technology for fabricating diffraction gratings used in advanced displays. Photo by KERI

Dr. Pyo stated, "This is a world-class 3D printing technology that can accurately implement desired structural colors at desired locations without restrictions on substrate materials or shapes," adding, "It can overcome the limitations of standardized form factors in display devices and enable diversification of shapes."

The research results were published as a cover paper in 'ACS Nano,' a materials science journal issued by the American Chemical Society.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)