Successful Localization Based on Reliable Demand

Start of Orders for High-Heat-Dissipation Spacers for Vehicle Power Semiconductors

The Only Company to Achieve Vertical Integration from Materials to Package Products

Recently, interest in new technologies and next-generation materials has grown in the domestic stock market. As the secondary battery market expands, supply and demand concentrated on material companies, then shifted to superconductors. As the market-leading theme changes, material companies are being re-evaluated in terms of value. The financial investment industry expects companies related to next-generation semiconductors to also undergo corporate value reassessment.

Major global system semiconductor companies have entered a competition to dominate the next-generation power semiconductor market. Domestic companies such as Samsung, SK, and LX are also advancing their next-generation power semiconductor businesses. Next-generation power semiconductors are made by fabricating devices on wafers created by combining various chemical elements. Using silicon carbide (SiC) and gallium nitride (GaN) allows for chips that are more heat-resistant and compact compared to silicon-based chips.

Market research firm TrendForce projected that the SiC chip market size will grow from $2.275 billion this year to $5.328 billion by 2026. Of the 2026 market size, 74% will be occupied by automotive chips. Automakers are trying to secure supply in advance, considering the complexity of the manufacturing process for next-generation power semiconductors. This is why the price of next-generation power semiconductors is rising.

Samsung Electronics is preparing its power semiconductor business within its foundry division. At the recently held ‘Samsung Foundry Forum 2023,’ it announced, "Starting in 2025, we will begin foundry services for 8-inch GaN power semiconductor products for consumer, data center, and automotive applications." Samsung Electronics is known to have formed a power semiconductor task force (TF) team within its DS division to review business performance and technological advancement.

SK Group entered the power semiconductor market through mergers and acquisitions (M&A). SK Siltron acquired the SiC wafer business from the US company DuPont in 2019 and plans to invest about 820 billion KRW to expand facilities by 2025.

Successful Localization of Spacers for SiC Power Semiconductors

As applications for SiC and GaN power semiconductors increase, demand grows for 'low thermal expansion, high thermal conductivity materials,' essential for semiconductor chip mounting substrates. The high output and high integration of system semiconductors increase heat generation. Costexis plans to secure production capacity worth 110 billion KRW in total, including 50 billion KRW for RF packages and 60 billion KRW for thermal spacers, in preparation for rising demand.

After three years of preparation, Costexis is discussing spacer supply with major global companies. Following reliability tests at Hyundai Motor’s research center, it is in the quality review stage for mass production with Hyundai Mobis. It is also conducting tests with LG Magna, Vitesco, and Sanken. As part of Korean investments, it supplies samples to ON Semiconductor, which mentioned expanding SiC power semiconductors. Additionally, there is potential for expansion with NXP’s automotive power semiconductors, and substrate approval for Wolfspeed has been completed. NXP is also well known as a company Samsung once considered acquiring but dropped after last-minute price negotiations failed.

Kim Hak-jun, a researcher at Kiwoom Securities, said, "Electric vehicle semiconductors currently focus on Si semiconductors," and predicted, "The market will rapidly shift to SiC power semiconductors." He added, "Switching from Si to SiC is expected to bring two effects: more than 10% improvement in power efficiency and reduction in component size," explaining, "The power semiconductor spacers developed by Costexis are essential materials for SiC semiconductor chip mounting substrates, featuring low thermal expansion and high thermal conductivity."

SiC power semiconductor modules use two double-sided DBC substrates (insulating substrates) to dissipate heat. Power semiconductors such as SiC or GaN are mounted on spacers. Costexis developed materials with thermal expansion coefficients similar to semiconductors. It succeeded in internalizing everything from materials to products. Costexis is the only company in the world that has vertically integrated from materials to packaged products, producing everything in-house.

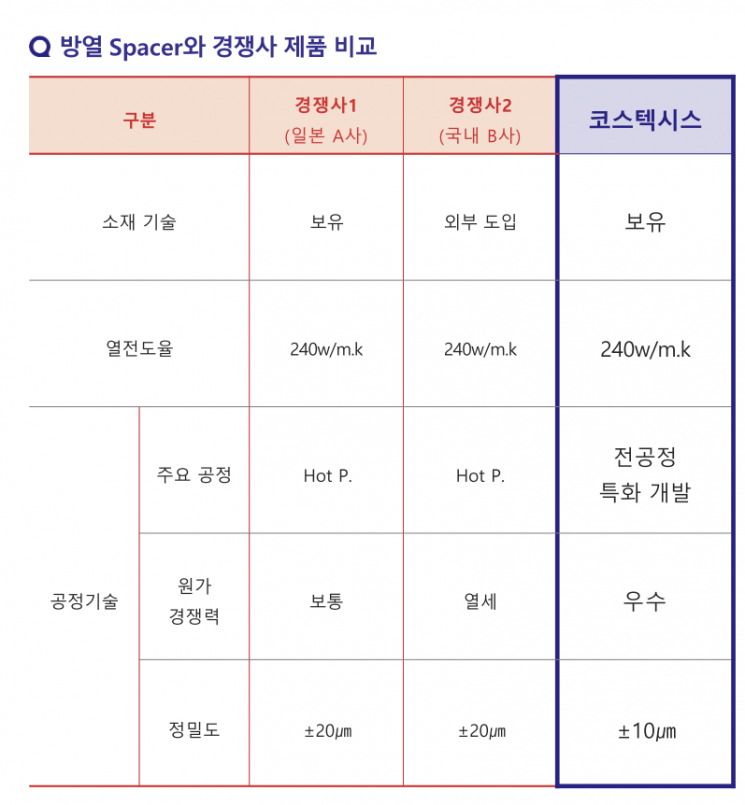

Recognized for its technology by global electric vehicle companies, Costexis participates in numerous collaborative developments. It developed a high thermal conductivity CMC40 material with a thermal expansion coefficient below 6.8 PPM/℃ and thermal conductivity above 180 W/m·K. It is also involved in next-generation power module development. Thermal spacers for power semiconductors are dominated globally by Japanese companies A and F. In Korea, these are entirely imported from Japan. Costexis’s high thermal conductivity materials, CMC and CPC, have superior thermal conductivity and price competitiveness compared to competitors. It supplies prototypes to automotive manufacturers. It is closely collaborating from the development stage on power semiconductor thermal spacer components with global automakers planning mass production of SiC power semiconductors for electric vehicles. Large-scale orders are expected once mass production begins.

Last month, Costexis signed an initial supply contract for high thermal conductivity spacers for automotive power semiconductors with a global power semiconductor specialist company. Costexis’s automotive high thermal conductivity spacers are key material components for next-generation compound power semiconductors such as SiC and GaN, which have recently attracted market attention. They have been tested by several global semiconductor companies.

Costexis CEO Han Kyu-jin said, "We have been in extensive discussions with leading domestic and international companies related to automotive power semiconductors," adding, "Mass production orders are proceeding faster than expected." He continued, "We could feel that the overall automotive power semiconductor market is accelerating," and emphasized, "It is significant that orders are moving beyond the testing phase to the mass production stage."

Based on competitiveness from applying self-developed core thermal materials to radio frequency (RF) packages, Costexis counts global semiconductor company NXP as a key client. It plans to lead overseas markets through full-scale sales of 5G communication RF packages and investment in mass production facilities for low thermal expansion, high thermal conductivity spacers for next-generation power semiconductors for electric vehicles.

Recognized for its technological capabilities, Costexis was selected as a joint research and development institution for the Ministry of Trade, Industry and Energy’s materials and components technology development project. The government project is titled ‘Development of Ultra-High Frequency GaN MMIC (Microwave Monolithic Integrated Circuit) Dedicated Package and Post-Packaging Process Development.’ Costexis is responsible for developing ultra-high frequency low-loss, high thermal conductivity, inspection function path-providing GaN MMIC dedicated packages and implementing thermal design that facilitates heat dissipation from power devices.

Costexis achieved sales of 25.3 billion KRW and operating profit of 3.57 billion KRW last year. In the first quarter of this year, it recorded sales of 2.3 billion KRW and an operating loss of 300 million KRW.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)