Visiting POSCO's Battery Heart 'Gwangyang'

② POSCO Group's 'Power of Battery Circulation'

From Precursors and Lithium Hydroxide to Battery Recycling

POSCO Establishes Cathode Material Circular Ecosystem

Lithium, known as 'white petroleum,' and nickel, which has emerged as the 'crown prince' of the electric vehicle battery era, ultimately generate profit in factories. The 'Gwangyang Secondary Battery Complex' of the POSCO Group, located in the Yulchon Industrial Complex in Gwangyang-si, Jeollanam-do, is a place that consolidates such battery material factories.

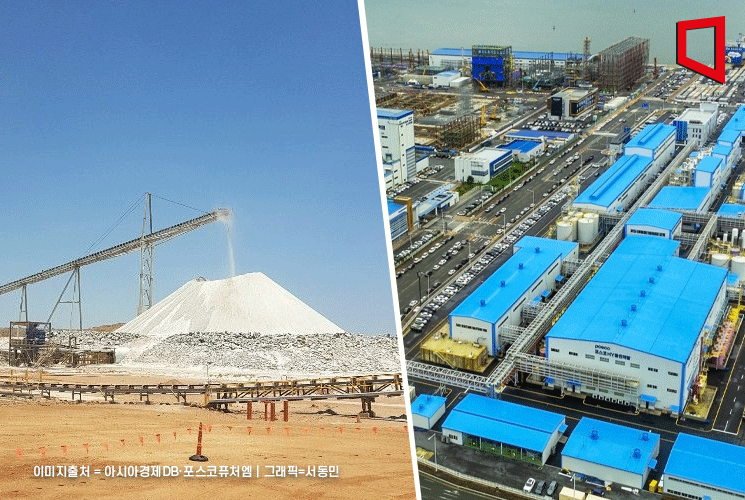

This site is completing POSCO Group's battery value chain competitiveness, spanning from raw materials to materials and recycling. It includes the POSCO Future M cathode material plant producing cathode materials, POSCO Philbar Lithium Solution producing lithium hydroxide, and POSCO HY Clean Metal plant extracting battery raw materials from scrap and waste batteries. The total site area of these three factories near Gwangyang Port is 532,000㎡ (approximately 169,300 pyeong), equivalent to the size of 75 soccer fields. POSCO Group announced on the 2nd of this month that it plans to invest about 73 trillion KRW centered on Gwangyang and Pohang by 2030.

Panoramic view of POSCO Group Gwangyang Secondary Battery Materials Complex. Photo by POSCO Future M.

Panoramic view of POSCO Group Gwangyang Secondary Battery Materials Complex. Photo by POSCO Future M.

The POSCO Future M Gwangyang plant has the capacity to produce not only cathode materials but also precursors, which are intermediate raw materials for cathode materials. The domestic battery industry has long depended on China for precursors. This has raised issues such as supply-demand imbalances and the possibility of exclusion from subsidies by major countries. POSCO Future M plans to expand its precursor production capacity from the current 5,000 tons to 50,000 tons next year.

The POSCO Philbar Lithium Solution plant, which produces lithium hydroxide from lithium spodumene (ore) imported from Australia, is in the final stages of construction ahead of its completion in October this year. As of July, the construction progress rate is 54.5%, with the second plant scheduled for completion in October and the first plant in February next year. This plant is expected to produce 43,000 tons of lithium hydroxide annually. Son Dong-gi, head of the cathode material division at POSCO Future M, said, "The lithium required to produce 90,000 tons of cathode materials at the POSCO Future M Gwangyang plant is about 41,000 tons," adding, "The lithium hydroxide produced by Philbar Lithium Solution alone can support the current scale of cathode material production."

The POSCO HY Clean Metal plant was completed on the 7th of this month. It can process 12,000 tons annually of black powder (a black powder containing various metals obtained after crushing waste batteries). This amount corresponds to the waste battery volume from approximately 85,000 to 100,000 electric vehicles, assuming about 120 to 140 kg per vehicle. POSCO HY Clean Metal extracts 2,500 tons of nickel, 800 tons of cobalt, and 2,500 tons of lithium carbonate from this black powder. Currently, the plant operates with a recovery rate target of 99% for nickel and over 90% for lithium. Kim Ji-hoon, marketing team leader of POSCO HY Clean Metal's business operations office, said, "Currently, the main raw materials are scrap generated during the battery manufacturing process (fragments and waste produced during product manufacturing)" and added, "Considering the battery production scale, it can process scrap from battery plants with a capacity of about 70 GWh (more than 700,000 electric vehicles)." The plant is currently processing scrap from LG Energy Solution's plant in Poland.

POSCO Future M plans to further enhance its global competitiveness through the Gwangyang Secondary Battery Material Complex. By processing and producing key raw materials domestically, it aims to reduce dependence on China and effectively respond to supply chain issues such as the U.S. Inflation Reduction Act and the EU's Critical Raw Materials Act (CRMA). A POSCO Future M official stated, "We plan to increase the annual cathode material production capacity to 1 million tons by 2030."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.