Robot component technology capable of creating versatile tongs that can pick up even potato chips without breaking them, and wearable elbow suits that reduce muscle strain has been developed.

The research teams led by Professor Kim Ji-yoon from the Department of Materials Science and Engineering and Professor Bae Jun-beom from the Department of Mechanical Engineering at Ulsan National Institute of Science and Technology (UNIST) developed a ‘soft valve’ technology, a component that maximizes the advantages of soft and flexible soft robots.

This tube-shaped component senses external stimuli and precisely controls the movement of the actuator without electricity, functioning as a dual-purpose part.

Since it can operate without electricity, it can be safely used underwater or in environments where sparks occur, and as a dual-function component, it enables the lightweight design of robots. The cost is also low, about 800 won per component.

Professor Kim Ji-yoon explained, “Unlike the soft and flexible soft robot body, sensors for stimulus detection and actuator control parts have often been rigid electronic components, but in this study, the sensor and actuator control parts were also made from soft and flexible materials.”

The research team used this soft valve to create versatile tongs that can easily pick up various objects. These tongs successfully grasped everything from fragile potato chips that easily crumble with hard robot hands to heavy and bulky wooden blocks. They also worked well in environments with sparks and underwater.

Additionally, using this component, they developed a wearable elbow assist robot that effectively reduces muscle strain in the arm. The assistive force on the elbow automatically increases according to the angle of the bent arm. When wearing the robot, the force applied to the elbow was found to decrease by an average of 63%.

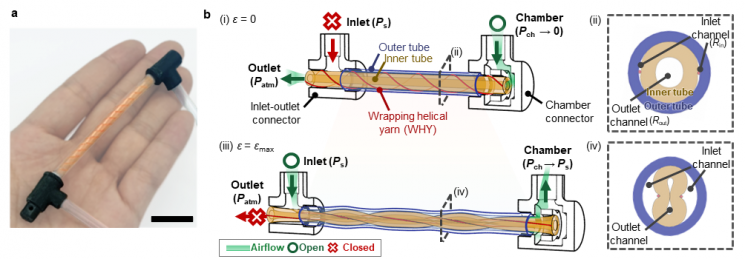

The soft valve operates the actuator by air flowing inside the tube.

When the tube end is pulled, a thread spirally wound inside the tube presses the tube to control the inflow and outflow of air. Pulling the tube end causes the actuator to expand and contract like an accordion bellows.

Furthermore, the research team confirmed that by precisely programming the structure and number of threads wound around the tube, the inflow and outflow of air can be variably controlled. Even when the same force is applied to the tube end, the actuator can be adjusted appropriately according to the shape and number of the wound threads.

Professor Bae Jun-beom from the Department of Mechanical Engineering explained, “The developed component can be easily used without electronic elements by utilizing material programming, which will greatly contribute to the development of various wearable systems.”

This research was published online on July 4, 2023, in the international journal Nature Communications. The research was supported by the Ministry of Science and ICT, the National Research Foundation of Korea (NRF), the Korea Institute of Materials Science (KIMS), and the Korea Evaluation Institute of Industrial Technology (KEIT).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.