[Hyundai High-Performance Electric Vehicle Unveiled]

Equipped with Various New Technologies to Realize N Brand Value

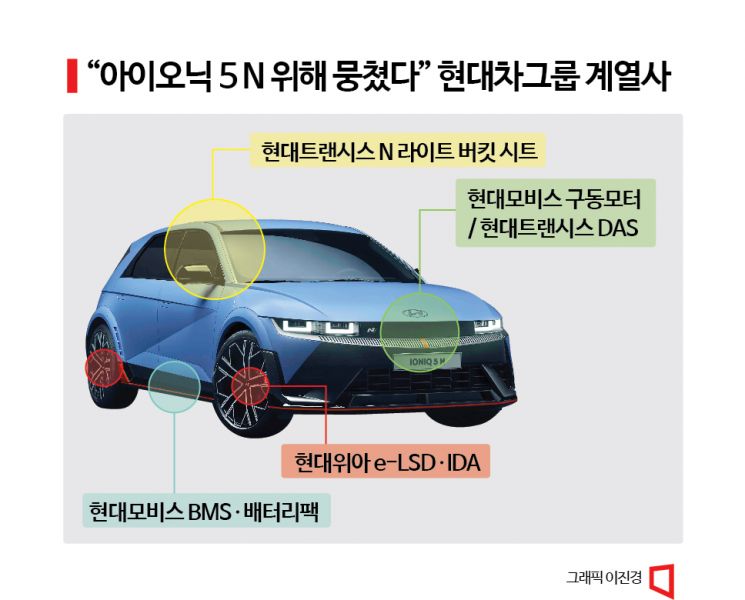

Hyundai Mobis, Wia, Transys and Other Affiliates Fully Mobilized

Utilizing 'Vertical Integration' Advantages from Drive Motor to Seats

The Ioniq 5 N, Hyundai Motor's first high-performance electric vehicle, is a car that embodies Hyundai Motor Group's advanced electrification technology. Not only did it incorporate newly developed technologies, but each group affiliate also honed its own capabilities. It fully leveraged the advantages of a vertically integrated complete car manufacturer.

Hyundai Motor introduced new technologies to the Ioniq 5 N with three goals in mind: ▲improving cornering performance ▲achieving driving capabilities suitable for race tracks ▲and creating a sports car that can also be used in everyday life.

First, to enhance cornering ability, Hyundai Motor applied the ‘hydro mount’?which reduces vibrations during driving?for the first time in its vehicles. Electric vehicles are heavier than internal combustion engine vehicles of the same class, which inevitably causes more body roll, but this was reduced by utilizing fluid inertia. This improved ride comfort and made handling more stable. The integrated drive axle (IDA), used in World Rally Championship (WRC) rally cars, was applied to both the front and rear wheels. By integrating the wheel joint and hub, the number of parts and weight were reduced. An electronic limited-slip differential (e-LSD), which actively controls the driving force of the left and right wheels, was applied to reduce understeer (the tendency to push outward during cornering when accelerating) and enable sharp exits from curves.

The high-performance rear motor was applied with track driving in mind. A 2-stage motor system equipped with two inverters controlling motor speed was used; normally, only one inverter operates, but at high speeds, both operate.

The virtual transmission system ‘N e-Shift’ and virtual sound system ‘N Active Sound Plus’ enhance driving enjoyment. They allow drivers to experience the shifting sensation and engine sound typical of internal combustion motorsport vehicles. Two external speakers are also installed to clearly announce that this is a high-performance car.

To equip these technologies, Hyundai Motor Group affiliates collaborated closely. According to our comprehensive reporting, Hyundai Mobis supplied the drive motor, battery management system (BMS), and battery pack for the Ioniq 5 N. Hyundai Wia provided the e-LSD and IDA, contributing to the vehicle’s improved handling and cornering performance. Hyundai Transys supplied the N light bucket seats and DAS (a device that separates or connects the motor and drive shaft depending on driving conditions to switch between two-wheel and four-wheel drive). These seats reinforce the side bolsters to support the driver even during sharp cornering. DAS reduces unnecessary power loss, thereby extending the electric vehicle’s driving range.

Starting with the Ioniq 5 N, collaboration among group companies is expected to accelerate further. At the Uiwang Research Center, where research institutes of Hyundai Motor Group affiliates are gathered, Hyundai Mobis has established a research building overseeing the group’s entire electrification efforts; Hyundai Motor and Kia have set up battery development departments; and Hyundai Wia has prepared an electric vehicle thermal management testing facility, all conducting research.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

!["I'd Rather Live as a Glamorous Fake Than as a Poor Real Me"...A Grotesque Success Story Shaking the Korean Psyche [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)