Professor Kim Seok-jun's Team at Korea University of Technology and Education Develops New Technology

A domestic research team has developed the world's first lithium metal secondary battery with an anode material coated in metallic glass, achieving a lifespan more than twice as long as existing batteries.

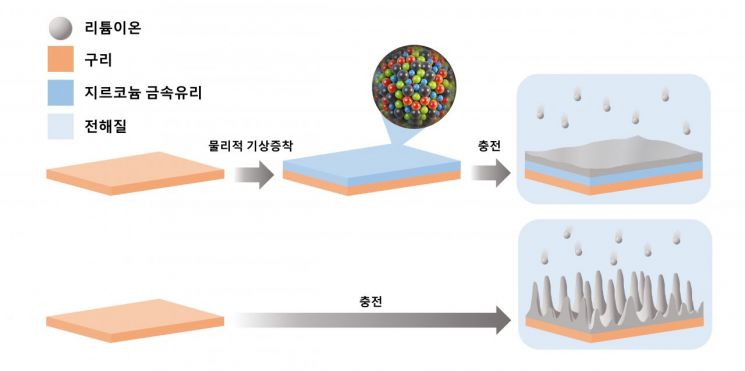

The National Research Foundation of Korea announced on the 22nd that Professor Kim Seok-jun's research team at Korea University of Technology and Education developed a technology that coats metallic glass on the current collector and lithium anode surface of secondary batteries to improve the lifespan of anode-free and lithium metal secondary batteries.

Metallic glass refers to an alloy in an amorphous state where the arrangement of metal atoms becomes disordered like glass when molten metal is rapidly supercooled below its melting point. It is widely used in golf heads, tennis rackets, and mobile phone cases. As demand for secondary batteries in electric vehicles and eco-friendly mobility increases significantly, there is a growing need for next-generation secondary batteries with larger capacity and faster charging than the currently most used lithium-ion batteries. In particular, research is actively underway to increase battery energy density by eliminating bulky and heavy anode materials or replacing conventional graphite anodes with lithium metal and other materials.

Such anode-free batteries or lithium metal secondary batteries can increase gravimetric energy density by about 1.5 times compared to conventional lithium-ion batteries. However, lithium metal is continuously exposed to the electrolyte, and side reactions with the electrolyte consume lithium, shortening battery life.

The research team identified metallic glass, an alloy with a disordered atomic structure like glass, as an optimal coating material for secondary batteries. While previous studies have explored polymers, oxides, and crystalline metals as anode coating materials, this is the world's first research applying metallic glass. Because metallic glass lacks regularity in atomic arrangement similar to liquids, it has very few defects, resulting in a uniform surface and excellent corrosion resistance. By coating this material on the current collector and lithium metal anode surface, uniform lithium deposition during charging was induced, minimizing the contact area between charged lithium and the electrolyte, thereby improving cell performance. Metallic glass acts as a protective film for the lithium metal anode within the battery, where oxidation and reduction reactions are active, suppressing side reactions with the electrolyte and dramatically enhancing cell lifespan. In the case of lithium metal batteries, full cells using lithium iron phosphate cathodes demonstrated long-life characteristics exceeding 1800 cycles.

Professor Kim stated, “Metallic glass-coated lithium metal can be applied in environments that manufacture currently commercialized secondary batteries, which is expected to greatly aid the mass production of lithium metal secondary batteries.”

This research achievement was published last month on the 8th in the international journal on surfaces and interfaces, Small.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)