KIST-KAIST Joint Research Team

Domestic researchers have developed a technology that can enhance the performance and safety of platinum catalysts used in hydrogen vehicle fuel cells by utilizing artificial intelligence (AI).

On the 14th, the Korea Institute of Science and Technology (KIST) announced that Dr. Hansangsoo and Dr. Kim Donghoon from the Computational Science Research Center, together with Professor Lee Hyukmo from the Department of Materials Science and Engineering at the Korea Advanced Institute of Science and Technology (KAIST), developed a new AI technology capable of rapidly and accurately constructing surface Pourbaix diagrams for platinum nanoparticles sized in the nanometer (nm) scale.

Proton exchange membrane fuel cells (PEMFCs), primarily used in hydrogen vehicles, mainly employ platinum (Pt)-based catalysts. Since the performance of the catalyst is directly linked to the lifespan of the fuel cell, research to improve the performance, especially the stability, of platinum catalysts is essential. Using surface Pourbaix diagrams allows prediction of the surface structure and stability of catalyst materials under actual operating conditions. Surface Pourbaix diagrams can be obtained through adsorption energy simulation calculations using density functional theory (DFT), but for platinum catalysts with nanometer-sized nanoparticle structures, this process takes thousands of hours.

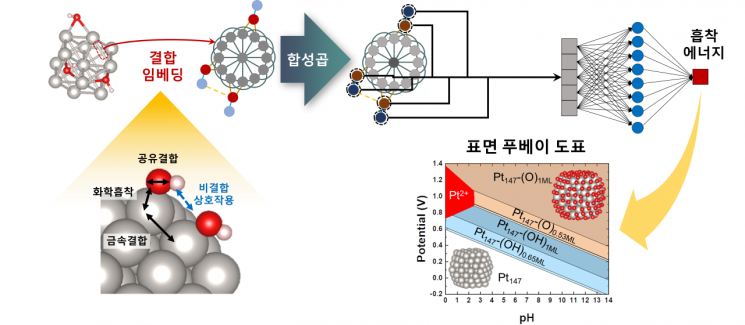

The research team developed a Bond Embedding-Crystal Graph Convolutional Neural Network (BE-CGCNN) model to accurately predict the energy with which adsorbates bind on the catalyst surface. They introduced bond embedding technology, which considers the types of atomic bonds, into the existing Crystal Graph Convolutional Neural Network (CGCNN) model. Using the BE-CGCNN model, the adsorption energy of adsorbates on the surface of platinum nanoparticles can be predicted with an error margin of about 0.1 eV compared to DFT calculations, enabling precise construction of surface Pourbaix diagrams. Compared to the conventional CGCNN model, the error was reduced by up to 85.7%. For platinum nanoparticles approximately 5 nm in size, which are actually used in PEMFCs, the time required to calculate the surface Pourbaix diagram was only about 70 seconds. Using traditional density functional theory would take over a year for such calculations.

Dr. Han stated, “The BE-CGCNN model can be applied not only to platinum but also to predict the stability of various metal and alloy nanoparticles, making it useful for developing new catalyst materials with long lifespans.” Dr. Kim Donghoon added, “By utilizing this technology to develop new nanoparticle catalysts with high stability, the lifespan of fuel cells can be dramatically extended. Moving forward, we plan to secure training data for the model to apply it to various materials beyond platinum and to expand the deep learning model.”

The research results were published online on the 25th of last month in the international academic journal Nature Communications.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.