POSCO International will supply 6.85 million core eco-friendly vehicle parts to Hyundai Motor over 10 years. The supplied parts are drive motor cores produced by its subsidiary POSCO Mobility Solution. These are essential components required for the drive motor, the heart of eco-friendly vehicles.

On the 8th, POSCO International announced that its subsidiary POSCO Mobility Solution signed a supply contract with Hyundai Motor for 2.5 million drive motor cores. These parts will be installed in Hyundai’s next-generation premium flagship electric vehicles mass-produced from 2025 to 2034.

Previously, POSCO Mobility Solution secured contracts in November last year to supply 3.4 million motor cores for Hyundai’s next-generation hybrid sport utility vehicles (SUVs), and in January this year, a contract to supply 950,000 units for a compact electric SUV model. Including this additional order, POSCO Mobility Solution will supply a total of 6.85 million core parts over 10 years from 2025 to 2034.

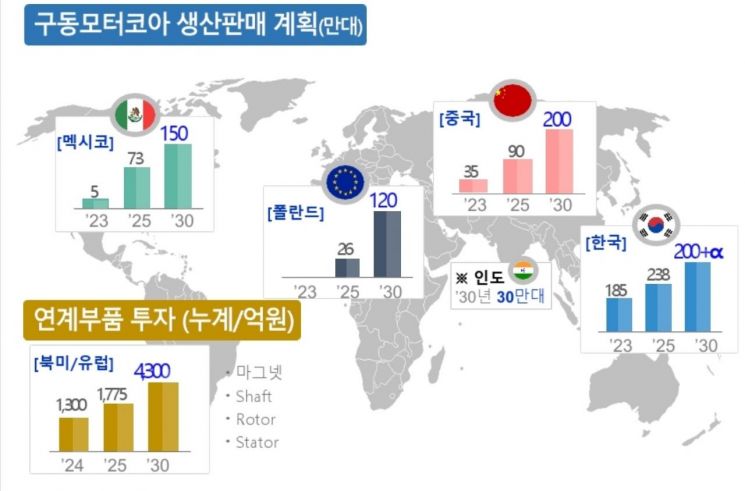

POSCO Mobility Solution, a subsidiary of POSCO International, is the leading domestic manufacturer of drive motor cores. Its strengths lie in proprietary patented technology and the ability to procure electrical steel sheets through POSCO. POSCO International operates overseas factories in North America, Europe, China, and other regions, aiming to establish a global production and sales system for over 7 million drive motor cores by 2030 and secure more than 10% of the global market share.

Domestically, production systems for 2 million drive motor cores have been established in Cheonan and Pohang to prepare for the explosive demand growth in the eco-friendly vehicle motor market. Overseas production systems capable of producing 5 million units by 2030 have also been established in China, Mexico, Poland, and India. Through this, trade barrier risks in the electric vehicle market such as the US Inflation Reduction Act (IRA) and the European Critical Raw Materials Act (CRMA) have been mitigated, meeting local procurement demands of automakers.

In China, a new factory with an annual production capacity of 900,000 units was launched in March last year and is scheduled for completion in the second half of this year. In Mexico, production is planned to start in earnest in the second half of this year with an annual capacity of 1.5 million units. In Europe, Poland was recently selected as a production base, with factory construction starting within this year and production targeted for the second half of 2025.

POSCO International is also expanding its eco-friendly vehicle parts distribution network utilizing its global network. Following $400 million in electric vehicle parts exports last year, it achieved $800 million in cumulative orders this year, doubling last year’s performance.

In particular, it plans to assist domestic small and medium-sized enterprises (SMEs) that previously manufactured internal combustion engine parts to transition into eco-friendly vehicle parts suppliers. Future plans include promoting local production to enhance the global competitiveness of domestic SMEs.

A POSCO International official stated, "Combining POSCO Holdings’ lithium procurement capabilities, POSCO’s automotive steel sheet production capacity, POSCO Future M’s cathode material production technology, and POSCO International’s eco-friendly vehicle parts manufacturing and distribution capabilities completes POSCO Group’s eco-friendly mobility value chain blueprint." He added, "We will become a leader in the future eco-friendly vehicle parts market by actively investing and integrating trading know-how."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.