GIST Research Team Also Demonstrates Process Simplification Effects

A technology has been developed that, when sprayed onto the surface of organic solar cells, self-coats to extend the lifespan of the solar cells by up to 24 times and also achieves process simplification effects.

The Gwangju Institute of Science and Technology (GIST) announced on the 30th that Dr. Kang Hong-gyu from the Next Generation Energy Research Center, Director Lee Kwang-hee, and a joint research team from Imperial College London in the UK succeeded in simplifying the coating process of organic solar cells and securing high efficiency and long lifespan by utilizing a material that forms a thin layer by itself.

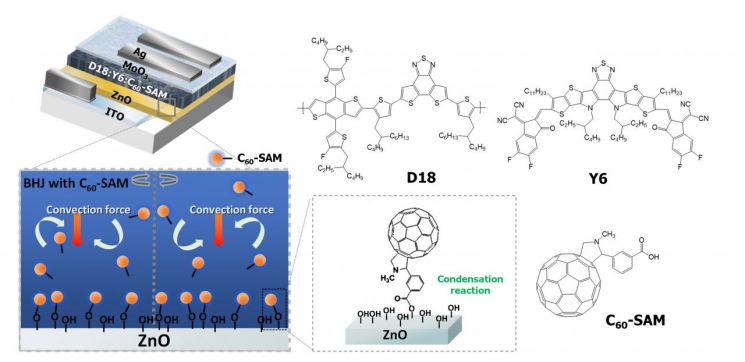

Schematic diagram of the organic solar cell structure, molecular structures of the photoactive material and C60-SAM material, and the vertical self-assembly mechanism. Photo source provided by GIST

Schematic diagram of the organic solar cell structure, molecular structures of the photoactive material and C60-SAM material, and the vertical self-assembly mechanism. Photo source provided by GIST

This research achievement was published on the 25th of last month in the international journal in the field of materials science, Advanced Science.

Organic solar cells have advantages over inorganic solar cells using silicon in that they are cheaper, lighter, flexible, and transparent.

In particular, they can be used in various industries by attaching films to windows of buildings and cars or glass greenhouses, leading to continuous research efforts.

Among them, zinc oxide, widely used in inverted-structure organic solar cells, has high light transmittance and excellent charge transport capability, but when it absorbs ultraviolet rays, it causes a photocatalytic phenomenon that decomposes the photoactive layer that generates electricity. In this case, the ability to absorb light decreases, significantly reducing electricity production efficiency. Attempts have been made several times to apply a passivation layer on zinc oxide, but complex coating processes caused manufacturing costs to rise.

The research team applied a monomolecular material called ‘fullerene-based self-assembled material (C60-SAM)’ onto zinc oxide to form a protective layer by itself, thereby securing the stability of zinc oxide, improving the efficiency and lifespan of the cell, and also simplifying the coating process. C60-SAM takes advantage of forming a thin layer on the surface when it meets zinc oxide. The team mixed C60-SAM with the photoactive material for coating and allowed it to react with zinc oxide to form the protective layer by itself. A condensation reaction occurred between the carboxylic acid terminal group of C60-SAM and the hydroxyl group on the zinc oxide surface, enabling the stable formation of the protective layer in between.

In particular, the time taken for the efficiency of the organic solar cell to drop by 10% was greatly improved from about 20 minutes to 8 hours, an increase of approximately 24 times.

Dr. Kang said, “It is significant that we solved the stability problem occurring between the electron transport layer and the photoactive layer of inverted-structure organic solar cells by forming a protective film using a self-assembled layer, a new method,” adding, “Even reducing the coating process by one step can greatly improve mass production feasibility, which will be a great help for commercialization of organic solar cells.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.